Manufacturing today runs on data. Machines, sensors, ERP platforms, and supply chains produce massive streams of information every second. The challenge is no longer collecting data, but connecting it. Yet, 82% of enterprises report that data silos disrupt their critical workflows, and as much as 68% of enterprise data goes unanalyzed. It locks away where it can’t support decision-making. Too often, systems remain isolated, creating blind spots that hinder productivity and responsiveness.

Big data integration solves this. It combines data from multiple sources and makes it accessible in real-time. Using techniques such as ETL, streaming pipelines, APIs, or cloud-native integration, manufacturers can create a single, consistent view of their operations.

As data analytics initiatives 2025 move forward, the focus is on how effectively companies use modern big data analytics platforms. For manufacturers, big data analytics services are no longer a support task; it’s a core driver of Industry 4.0.

Let’s dive into the big data integration techniques transforming manufacturing.

What is Big Data Integration?

Big data integration is the process of combining structured and unstructured data from multiple sources, such as IoT sensors, ERP systems, MES platforms, and cloud applications into a unified, consistent format that can be analyzed effectively.

Unlike traditional data integration, which focuses on smaller, static datasets, big data integration handles massive volumes of real-time information using techniques such as ETL, data virtualization, streaming pipelines, and API-based connections.

In manufacturing, this means:

-> Enabling predictive maintenance and process optimization.

-> Improving quality control and resource planning.

We’ve successfully implemented this in one of our projects for a global chemical manufacturer, where AI-powered data analytics streamlined operations and boosted efficiency — see the full case study here

Traditional vs. Modern Data Integration Techniques

Data integration has been around for decades. But the scale, speed, and complexity of big data in manufacturing have pushed the boundaries far beyond what traditional methods can handle.

Traditional data integration was built for smaller, structured datasets and slower reporting cycles. It worked well for static environments, but it cannot keep up with today’s manufacturing demands. Modern big data integration techniques are designed for speed, scale, and complexity.

Why Big Data Integration is Critical for Manufacturing Leaders

Manufacturing today generates data at an unprecedented scale—ranging from IoT sensors on the shop floor to ERP systems and legacy platforms. Yet, despite this abundance, many organizations still struggle with siloed and disconnected information.

When these silos are broken, the results can be transformative. Deloitte found that connected data systems improve operational efficiency by 10% to 20%.

For manufacturers, the message is clear: data integration is no longer optional. It’s the key to achieving operational excellence, enabling smarter decision-making, and building innovation-ready factories of the future.

1. Eliminating Operational Blind Spots

- IoT in manufacturing provides real-time insights into machine health and the status of production lines.

- ERP systems track operations, inventory, and financials across departments.

- Legacy systems often hold valuable historical data that remains untapped.

Bringing all these systems together transforms scattered data into a single, actionable view.

2. Make Decisions with Confidence, in Real Time

- Gain instant visibility into KPIs, supply chain performance, and equipment status.

- Predict maintenance needs before machines fail.

- Allocate resources dynamically to maximize throughput and efficiency.

Leaders can shift from reactive firefighting to a proactive strategy.

3. Unlock Deeper Insights and Continuous Improvement

- Analyze data across IoT, ERP, and MES systems to uncover hidden patterns.

- Forecast demand, capacity, and inventory with higher accuracy.

- Identify process bottlenecks and continuously optimize workflows.

Analytics stops being a post-mortem exercise and becomes a driver of operational excellence.

4. Gain a Competitive Edge

- Accelerate time-to-market by streamlining operations.

- Reduce costs and improve efficiency across the board.

- Leverage unified data to power AI, machine learning, and Industry 4.0 initiatives.

Data integration is the foundation for smarter, faster, and more resilient manufacturing.

For effective decision-making, manufacturers should rely on advanced analytics services that industry leaders trust. Our services have been recognized among the “Top 100+ Big Data Analytics Companies”, reflecting our commitment to helping manufacturers turn data into actionable insights. Contact our team to explore how our solutions can enhance your operations.

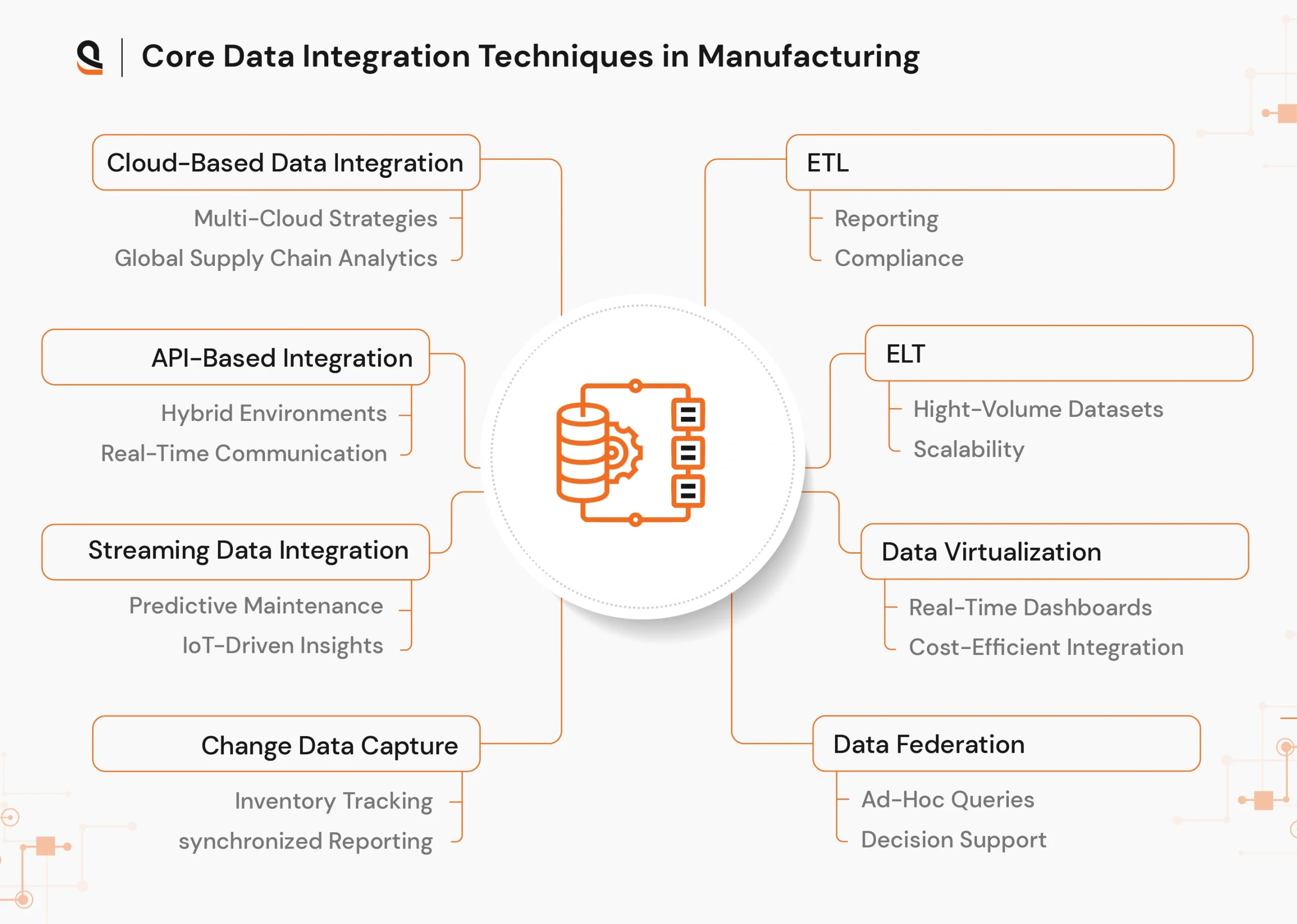

What Are the Core Data Integration Techniques in Manufacturing?

Effective enterprise data integration requires a thoughtful approach that aligns technical execution with strategic outcomes.

Each data integration technique serves a distinct purpose, helping manufacturing leaders convert fragmented data into actionable insights.

ETL (Extract, Transform, Load)

Building scalable ETL data pipelines has become essential for modern manufacturers. ETL has long been the backbone of data integration. It works by extracting data from multiple sources, transforming it into a standard structure, and loading it into a warehouse or data lake.

For manufacturers, ETL is often used to consolidate ERP transactions, CRM records, and historical production data.

It is reliable and well-understood, but because it processes data in batches, it can’t keep up with real-time factory operations.

Best suited for: reporting, compliance, and trend analysis.

ELT (Extract, Load, Transform)

ELT flips the traditional model. Instead of transforming data before storage, raw data is loaded first into a modern platform like Snowflake, BigQuery, or Azure Synapse, and then transformed as needed.

This approach takes advantage of the massive processing power of today’s big data analytics platforms.

For manufacturers, this means faster handling of IoT sensor data, large-scale supply chain records, and production metrics.

Best suited for: high-volume datasets, fast analysis, and scalability in Industry 4.0 environments.

Data Virtualization

With data virtualization, the data doesn’t have to be moved. Instead, a virtual layer connects multiple systems and presents a unified view of information.

Manufacturers can view ERP, MES, and IoT data on a single dashboard without replicating datasets or incurring additional storage costs.

This technique is valuable for leaders who need quick, real-time insights without building heavy integration pipelines.

Best suited for: real-time dashboards, quick analytics, and cost-efficient integration.

Data Federation

Data federation is often compared to virtualization, but it is more focused on query-level integration.

A single query can pull results from multiple databases, even if the data lives in separate systems.

While it’s not ideal for very large datasets, it works well when a manufacturer needs fast answers to specific business questions without merging entire data lakes.

Best suited for: ad-hoc queries, reporting, and decision support.

Change Data Capture (CDC)

CDC tracks changes in real time—like new transactions, updates, or deletions—and sends only that data downstream.

For manufacturers, this ensures that production data, supply chain inventories, and order systems are always synchronized without reloading everything.

It’s an efficient way to keep analytics platforms and business systems up-to-date with the latest activity.

Best suited for: inventory tracking, live production monitoring, and synchronized reporting.

Streaming Data Integration

Streaming is the lifeline of real-time manufacturing analytics. Using platforms like Apache Kafka, Apache Flink, or Spark Streaming, data flows continuously from machines and IoT devices.

This technique powers predictive maintenance by identifying equipment failures before they occur and enhances quality control through real-time anomaly detection.

For factories aiming to become brilliant factories, streaming is a must.

Best suited for: predictive maintenance, IoT-driven insights, and Industry 4.0 automation.

API-Based Integration

APIs (Application Programming Interfaces) create direct bridges between applications, platforms, and devices.

Manufacturers can use APIs to connect IoT devices with ERP systems, link MES with cloud analytics, or integrate third-party logistics platforms.

This approach is flexible, secure, and future-proof, making it easier to add or replace systems without re-engineering the entire data flow.

Best suited for: hybrid environments, custom integrations, and real-time system-to-system communication.

Cloud-Based Data Integration

Cloud-based integration utilizes tools such as AWS Glue, Azure Data Factory, or Google Dataflow to orchestrate and automate data movement.

It offers scalability and flexibility, allowing manufacturers to scale up when demand spikes or scale down when systems are idle.

For global enterprises, cloud-native integration ensures that data is available across regions while maintaining compliance and security.

Best suited for: multi-cloud strategies, global supply chain analytics, and scaling data analytics initiatives in 2025.

Advantages of Big Data Integration in Manufacturing

Integrating data isn’t just a technical upgrade, it’s a strategic enabler for smart manufacturing. By combining production data, IoT streams, supply chain records, and ERP systems into a single ecosystem, manufacturers gain the ability to act more quickly, reduce inefficiencies, and enhance decision-making.

Here’s how big data integration in manufacturing creates real-world impact:

1. Improved Operational Efficiency

- Unified data eliminates silos between ERP, MES, and IoT platforms.

- Managers get a single source of truth, reducing duplication and manual reporting.

- Enables lean manufacturing practices by highlighting waste, delays, or bottlenecks in production.

2. Real-Time Visibility and Monitoring

- Streaming and CDC-based integrations provide live updates from machines, sensors, and production lines.

- Helps track OEE (Overall Equipment Effectiveness), equipment downtime, and production status instantly.

- Leaders can respond to disruptions in real time instead of relying on delayed reports.

Get real-time visibility across your manufacturing operations – Connect with us

3. Predictive Maintenance

- Combining IoT sensor data with big data analytics enables manufacturers to forecast when machines are likely to fail.

- This minimizes unplanned downtime and avoids costly emergency repairs.

- Extends equipment lifespan while improving plant reliability and uptime.

4. Smarter Supply Chain Management

- Integration connects procurement, inventory, logistics, and demand forecasting systems.

- Manufacturers can anticipate material shortages, optimize stock levels, and ensure on-time delivery.

- Enables data-driven supplier collaboration by sharing real-time updates.

5. Enhanced Product Quality

- Data integration makes it possible to trace defects back to specific processes, machines, or suppliers.

- Combining quality inspection data with production metrics helps in root-cause analysis.

- Leads to fewer recalls, consistent quality, and higher customer satisfaction.

6. Faster and Better Decision-Making

- With a 360-degree view of operations, leaders can make proactive decisions.

- Advanced analytics and AI become more effective when they can pull from a centralized, integrated dataset.

- Reduces the gap between data collection and business action.

7. Scalability and Flexibility for Industry 4.0

- Cloud-based integration supports scalable data processing as production grows.

- New machines, IoT devices, or ERP modules can be added without breaking the data flow.

- This makes manufacturers future-ready for Industry 4.0 and smart factory adoption with AI-driven production & scheduling.

8. Cost Optimization

- Reduces the time and money wasted on manual reporting and disconnected systems.

- Prevents losses caused by downtime, excess inventory, and inefficient processes.

- Provides the foundation for ROI-driven digital transformation initiatives.

Big data integration in manufacturing is more than IT infrastructure—it’s the backbone of operational excellence, predictive intelligence, and competitive advantage.

Whether it’s predictive maintenance, real-time dashboards, or supply chain management, integrated data ensures manufacturers are not just collecting information but turning it into measurable business value.

Challenges in Big Data Integration for Manufacturers

While the benefits of big data integration are clear, many manufacturers struggle with the execution.

Legacy systems, fragmented platforms, and data quality issues often make integration complex. Here are the most common challenges:

1. Legacy Infrastructure

- Many plants still rely on outdated ERP or MES systems that don’t easily connect with modern big data analytics platforms.

- Upgrades or middleware are often needed, which can add cost and complexity.

2. Data Silos

- Information is locked within different departments—production, quality, supply chain, and maintenance.

- Without proper integration, leaders end up with incomplete visibility and delayed decision-making.

3. Data Quality and Standardization

- Manufacturing data comes from machines, IoT devices, and human inputs, often in different formats.

- Poor data quality or inconsistent data can undermine analytics, leading to faulty predictions.

4. Real-Time Processing Limitations

- Many manufacturers need streaming analytics but lack the infrastructure to process data instantly.

- This limits the ability to support predictive maintenance and live monitoring.

5. Scalability Issues

- As production expands, the volume, velocity, and variety of data grow rapidly.

- Legacy pipelines often fail to keep up with cloud-scale demands.

6. Security and Compliance Risks

- Data sharing across plants, suppliers, and cloud platforms increases the risk of breaches.

- Compliance with ISO, GDPR, and industry-specific standards adds another layer of complexity.

How AQe Digital Can Help Manufacturers in Big Data Integration

Recent big data polls in manufacturing show a clear trend: while most leaders recognize the advantages of big data integration, many still face barriers in execution.

These numbers underline a simple truth: collecting data is not enough—manufacturers need seamless data integration techniques to unlock real value.

At AQe Digital, we understand that manufacturers need more than just tools—they need a scalable integration strategy tailored to their operations. Here’s how we bridge the gap:

- Legacy System Modernization → We re-engineer ERP/MES platforms to work with modern data integration pipelines.

- Big Data Analytics Services → Using ETL/ELT, streaming, CDC, and API-based methods, we connect shop-floor data with cloud analytics platforms.

- Data Quality Management → We standardize and cleanse manufacturing data to ensure accuracy for predictive analytics.

- Cloud-Native Scalability → Our solutions leverage platforms like AWS Glue, Azure Data Factory, and Google Dataflow, ensuring manufacturers are future-ready.

- Security-First Approach → We implement robust encryption, access control, and compliance frameworks for safe data flow.

- Business-Focused Analytics Enablement → Beyond integration, we ensure your data supports predictive maintenance, supply chain optimization, and smart factory initiatives.

Final Takeaway

Big data integration is the backbone of modern manufacturing. It connects fragmented systems, delivers real-time visibility, and powers smarter decisions. Without it, scaling analytics and Industry 4.0 initiatives become nearly impossible.

The challenge is clear: legacy systems, data silos, and scalability issues hinder progress. The solution is to get an expert who knows both manufacturing workflows and modern data integration techniques. At AQe Digital, we help manufacturers unify data, enable predictive insights, and build scalable integration pipelines designed for the future.

With the proper integration, you don’t just manage data, you turn it into a competitive edge.

FAQs

We provide end-to-end data integration services that connect information from IoT devices, sensors, ERP systems, MES platforms, and legacy software. Our IT services for the Manufacturing industry ensure seamless data flow, helping you access real-time insights, improve operations, and make smarter decisions.

Our integration solutions break down data silos by combining data from multiple sources using ETL pipelines, APIs, event-driven workflows, and cloud integration. We create a unified data environment so your teams can access consistent, accurate information when they need it most.

Yes, we specialize in connecting both modern IoT devices and older legacy systems. Our team ensures that all data sources work together smoothly, without disrupting your current operations, allowing you to unlock insights from existing investments.

We enable real-time visibility by integrating live data streams and system interactions through APIs and event-driven pipelines. This empowers you to monitor production, maintenance, and supply chain activities as they happen, reducing downtime and improving efficiency.

Absolutely. Our cloud integration services set up scalable data lakes and analytics platforms that support advanced reporting, machine learning, and predictive analytics. We help you turn raw data into actionable insights that improve planning, forecasting, and overall performance.

Security is built into every stage of our integration process. We implement encryption, role-based access controls, monitoring, and compliance checks to ensure data is shared safely. Our solutions are designed for reliability, protecting sensitive information while supporting operational continuity.

Our services deliver faster reporting, improved data accuracy, and real-time operational visibility. Many of our clients begin to see measurable improvements—such as reduced downtime , better quality control, and faster response times—within weeks of implementation.

With expert-driven solutions and trusted services recognized among the “Top 100+ Big Data Analytics Companies,” we help manufacturing leaders integrate complex data environments efficiently. Our proven methods support better decision-making, operational resilience, and long-term growth.