Efficient supply chain management is crucial for the growth and success of textile manufacturers, regardless of size or location. A well-managed supply chain allows these manufacturers to respond quickly to market changes, maintain quality control, ensure timely product delivery, and achieve a better ROI with reduced operational costs. The textile industry’s intricate and complex supply chain requires robust digital solutions to manage vast inventories and streamline operations.

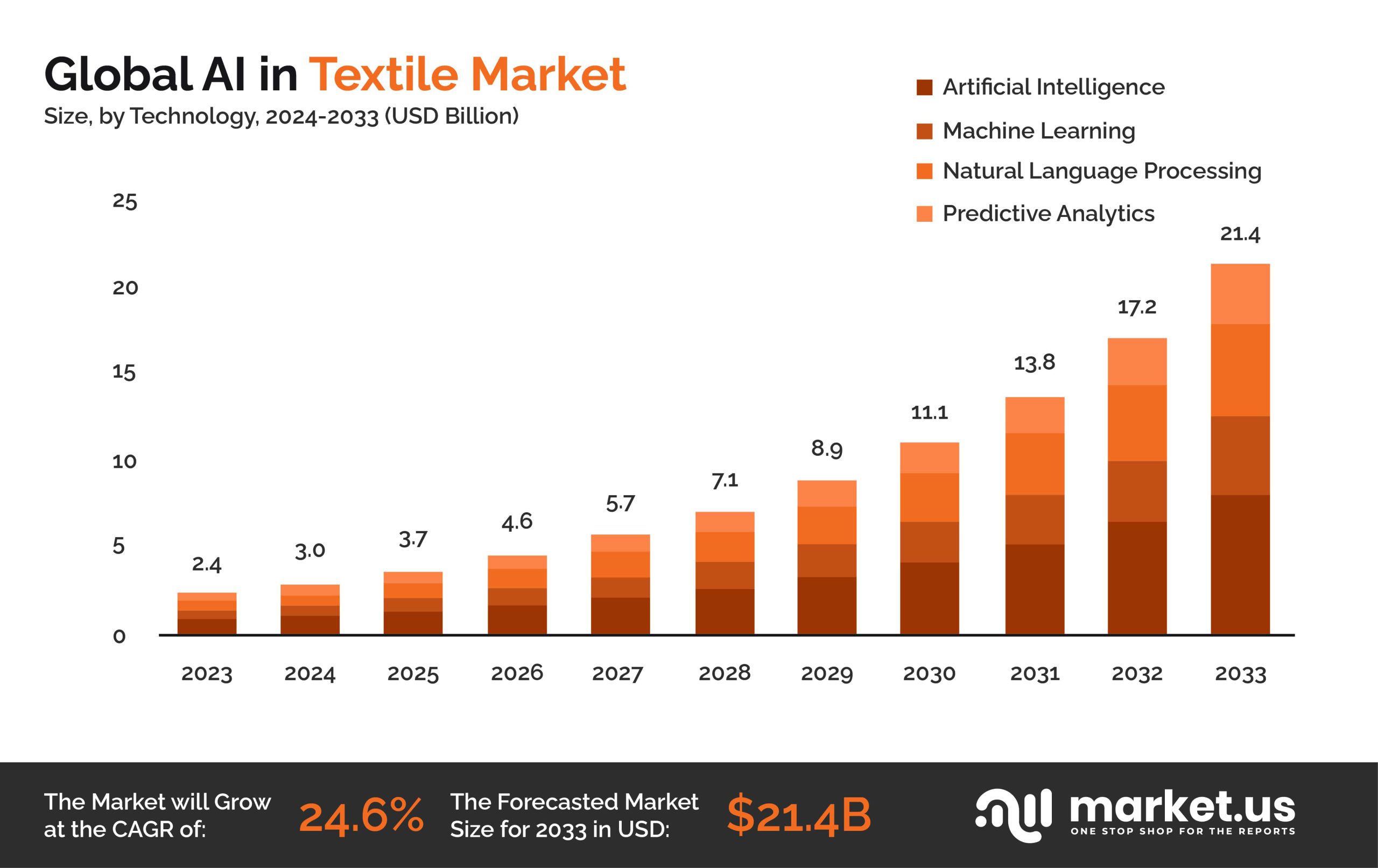

Following the challenges of supply chain management and foreseeing the market trends, textile manufacturers are increasingly turning to technologies especially Artificial Intelligence (AI) to optimize the supply chain management processes. According to Research and Markets, AI in supply chain management will reach $17.5 Billion by 2028.

Also, enabling an AI-driven supply chain can be 67% more effective with reduced risk and overall lower cost. Without efficient management, textile businesses face challenges such as overstocking, understocking, delayed deliveries, and decreased productivity, which can increase storage costs, result in missed sales opportunities, and cause revenue losses.

Why Is Supply Chain Management Optimization Important For Textile Industries?

The advent of online shopping and eCommerce trends has increased demand for fast fashion items. Generally, it is produced in large quantities and at a rapid speed to cope with the changing apparel life-cycle trends increasing the entire pressure on the supply chains of textile manufacturers. Such pressure on the supply chain has resulted in operational inefficiencies and unexpected disruptions, making textile manufacturers explore AI capabilities to optimize and streamline supply chain management.

Cost Efficiency

The textile industry is highly competitive and controlling costs is essential for profitability. Supply chain optimization with AI can help you procure raw materials at competitive rates from reliable vendors to reduce production costs. AI-driven supply chains can help textile manufacturers curb excess stock, minimize storage costs, and reduce the risk of material obsolescence or waste.

Speed to Market

Rapidly changing trends and consumer demands, especially in fast fashion affect the textile industry. Having an optimized supply chain helps textile manufacturers reduce lead times and enhance the production process. A smart supply chain streamlines the entire process- from raw material procurement to distribution. It helps textile manufacturers meet the market the needs, and consistently deliver the relevant products within less time.

Quality Control

Textile manufacturers can have better control over the overall manufacturing process with an efficient supply chain. Implementing technology-driven advanced quality control inspections helps manufacturers have the best product quality meeting industry standards and order requirements. Consistent quality strengthens customer trust as well as reduces the chances of returns and defects, enhancing overall manufacturing and supply chain efficiency.

Risk Management

Natural disasters, geopolitics, raw material shortages, or supply chain disruptions are the common risks faced by textile manufacturers. A well-planned textile supply chain builds resilience in the process by diversifying the suppliers and developing strategic plans to deal with unexpected risks. Additionally, smart supply chain management needs to ensure compliance with international trade regulations, labor laws, environmental standards, and diverse taxation. By managing such compliance textile manufacturers can mitigate associated risks such as legal penalties.

Customer Satisfaction

With an efficient supply chain textile manufacturers can meet the production schedules and deliver the orders on time. Manufacturers can offer products tailored to specific customer needs by enabling greater product flexibility. Well-managed supply chain apart from enhancing customer satisfaction, also strengthens relationships with clients and customers leading to more business and long-term growth.

Impact Of Inefficient Supply Chain On Textile Manufacturers

Increased Costs

Increases in transportation costs, higher inventory holding costs, expedited shipping fees, and reworks due to defects adversely impact operational costs.

Reduced Profitability

Higher operational costs due to overstocking-under stocking, and poor resource allocation can impact the overall revenue cycle reducing the profitability.

Delayed Production

The slow raw material procurement process, transportation delays, and production bottlenecks can delay the entire supply chain process.

Resource Misallocation

Poor planning and forecasting can disrupt inventory management leading to overstocking or shortages of raw materials.

Inventory Challenges

Excessive inventory results in capital hold and increases storage costs, while less stock can result in lost sales opportunities and production delays.

Quality Issues

The disrupted supply chain can lead to inconsistent product quality and non-compliance with regulatory standards resulting in product rejections and financial losses.

Order Fulfillment Issues

Inefficient supply chain results in order processing errors, delayed shipments, and inaccurate delivery information.

How Can We Help Enhance Supply Chain Management Efficiency Up To 30-35% For Textile Industries With AI?

Our data experts provide industry-specific AI solutions leveraging the latest tools and technologies for quick results. Explore how our team can help textile manufacturers with their AI/ML expertise.

50-60% Improved Inventory Forecasting

Our data experts can help textile manufacturers rapidly gather and process data from multiple sources to provide real-time data regarding the inventory to manage the supply chain using data collection and analytics techniques. Our predictive capabilities can help you predict future demand accurately to avoid under-stocking and over-stocking.

What You Get?

- Reduced overstock and understock situations

- 30-40% improved production planning

- 25-30% reduction in operational costs

Demand Forecasting

Leverage the capabilities of A with a time series analysis model for data-driven predictions considering multiple variables like seasonality, fashion trends, economic factors, and customer behavior. Track the dynamic consumer preferences, and market trends with deep learning processes by capturing complex patterns within your data for more precise forecasts. Stay agile, responsive, and competitive with an AI-integrated supply chain making the right products available at the right time.

- 40-50% accurate production planning

- 30-40% reduces waste

- 25-30% enhanced ROI

35-40% Better Distribution Process

AI integration within the supply chain can optimize logistics, route planning, and demand-driven distribution. With AI-powered tools, textile manufacturers can analyze historical sales data, real-time market trends, and customer locations to determine the most efficient distribution strategies. AI models can segment markets by prioritizing shipments with clustering and classifications from the available data.

What You Get?

- 30-35% Faster Deliveries

- 20-25% Cost-efficiency

- 50-60% enhanced customer satisfaction

Supplier Selection and Management

Our multi-criteria decision analysis can help you score and rank suppliers using AI/ML referring to various criteria like cost, quality, reliability, and delivery times. It helps in making more informed decisions when selecting suppliers. Additionally, integrating AI with the supply chain process helps manufacturers monitor supplier performance for on-time raw material delivery.

What You Get?

- 10-15% reduced raw material procurement cost

- 20-25% enhanced operational efficiency

- 30-40% quick decision-making

Supply Chain Visibility and Transparency

Have real-time visibility into every aspect of your production and supply chain operations using IoT devices for accurate tracking of raw materials and products. It helps you ensure a smooth production process and timely delivery of the order. With real-time data, manufacturers can make informed decisions and track the entire process to make any proactive measures required for a smooth supply chain.

- 20-25% enhanced transportation efficiency

- 40-50% more accurate order fulfillment

- 25-30% increases productivity

Predictive Maintenance

Leveraging IoT, IIoT sensors, and edge computing our data experts can help textile manufacturers have real-time visibility into every aspect of their operations. Using ML models like anomaly detection and regression models for failure predictions, our data experts can help you predict when a machine is likely to fail to avoid unexpected downtime and disrupted production processes. For textile manufacturers, it can help minimize downtime and avoid costly disruptions to production.

What You Get?

- 25-30% increased productivity

- 25-30% enhanced cost-effectiveness

- 60-70% accurate resource allocation

Why AQe Digital Is Preferred AI-Solution Provider For Textile Manufacturers?

D2M: No, it’s not about Direct To Mobile, it’s about Direct To Management. For every project we undertake the top brasses of our management get directly involved in ensuring top-notch service and timely delivery of the project. Speak with our CXOs; Offering direct access to our leadership team and industry experts, fostering transparency, swift decision-making, and a deep understanding of client needs.

Client-centric Co-creation: Collaborating closely with clients throughout the project lifecycle to innovate and develop solutions that align perfectly with their goals and requirements.

Agility and Flexibility: AQe Digital emphasizes agility and scalability enabling rapid adaptation to evolving data landscapes and business requirements. Unlike rigid solutions that struggle with agility, AQe Digital’s approach ensures swift responsiveness to market changes and operational demands.

Hyper-personalized Client Engagement: No one-size-fits-all; Tailoring our services to meet the unique needs and preferences of each client, ensuring a personalized experience that exceeds expectations.

Tailored SLAs: AQe Digital adapts service level agreements (SLAs) and contractual terms to your business objectives and risk management strategies, offering flexibility that standard approaches lack.

Conclusion

The impact of Artificial Intelligence (AI) on the textile industry is evident and long-lasting, especially in supply chain management. The entire industry is shifting towards smart manufacturing and intelligent supply chain management for better operational efficiency and to stay ahead of the curve for competitive advantage. With the progression of AI’s tools and technologies, it is expected to grow with its capabilities and advantages.

AQe Digital’s unwavering dedication to operational efficiency, transparency, and sustainable practices for the integration of AI into textile industries is setting a benchmark with each new project we are undertaking. Contact us to boost the potential of your supply chain management with our tailored AI solutions for better productivity, ROI, and efficiency.