The manufacturing world is shifting faster than ever, and robots in manufacturing are no longer a futuristic vision; they’re the backbone of modern production lines. Recent reports from global robotics bodies reveal an explosive adoption curve, with millions of robotic systems now powering every type of manufacturing unit across all industries. This surge is beyond automation as it is about redefining how industries operate in an age where precision, speed, and consistency decide who stays competitive.

With advancements in artificial intelligence (AI), sensors, and machine learning (ML), robotics in manufacturing has matured into a strategic advantage. What began centuries ago with the first industrial revolution, which included machines supporting human labour, has now evolved into fully integrated, intelligent systems that elevate quality, improve safety, and accelerate time-to-market. From welding and assembly to packaging, raw material handling, and shipping, robotic applications are expanding across every stage of the production floor.

And if you’re wondering whether robots are costly, overly complex, or reserved only for large enterprises, the reality is the complete opposite. Modern solutions are scalable, adaptable, and surprisingly accessible for small and medium-sized manufacturers.

In this blog, we’ll dive deep into how robotics is shaping the future of manufacturing, explore real-world applications, discuss benefits, break myths, and help you understand how it can help your business achieve growth, productivity, and accuracy.

What Is Robotics In Manufacturing?

Robotics in manufacturing refers to the use of automated, programmable machines designed to execute repetitive and complex industrial tasks with unmatched accuracy. These systems handle everything from welding and assembly to inspection, pick-and-place operations, packaging, and material movement, often performing the same process thousands of times with identical precision. Integrating robots in manufacturing helps bring a level of consistency and reliability that human workers can’t match in high-volume production environments. That doesn’t mean manufacturers don’t need human workers; robotics just helps manufacturers have better accuracy and productivity, collaborating with workers.

Modern robots, however, are no longer limited to fixed, repetitive tasks. Advances in sensors, machine vision, and intelligent software allow them to adapt their actions in real time, making them equally effective in low-volume, high-mix workflows where every unit may require a slightly different output. This evolution is also powering the rise of robotic process automation in the manufacturing industry, with systems that automate digital and physical workflows together to create faster, smarter production cycles.

Today’s factory floors include a diverse lineup of robots:

- Heavy-duty machines built to manage dangerous or high-risk materials

- Precision robots capable of manipulating microscopic components

- Autonomous mobile robots that navigate plants independently to move parts, tools, and finished products

With enhanced speed, safety, endurance, and intelligence, robots in manufacturing amplify human capability, freeing employees to focus on problem-solving, innovation, quality improvement, and higher-value strategic work.

How Emerging Technologies Amplify the Significance of Robotics in Manufacturing?

The latest wave of smart technologies is amplifying the benefits of robotics in manufacturing, transforming standalone machines into fully connected, intelligent automation systems.

Here is how key technologies are accelerating this shift:

-

The Industrial Internet of Things (IIoT)

IoT in the Manufacturing creates a connected network of machines, sensors, people, and workflows that continuously share data. This real-time intelligence empowers manufacturers to make smarter decisions, enhance product quality, and significantly reduce downtime across operations.

-

5G Connectivity

Delivers ultra-reliable, low-latency communication between robots and factory systems. Faster data transmission enables smoother coordination, precision control, and seamless automation across the smart factory.

-

Virtual Simulation

Allows engineers to model, test, and validate robot behavior in a digital environment before deployment. This reduces risks, accelerates installation, and ensures optimized robot performance from day one.

-

Virtual Platforms

Standardize and streamline automation across multiple applications. Manufacturers can reuse processes, simplify programming, lower maintenance effort, and scale robotics more cost-effectively.

To see how manufacturers are already leveraging automation to unlock measurable outcomes, explore our case study on digital transformation in manufacturing operations.

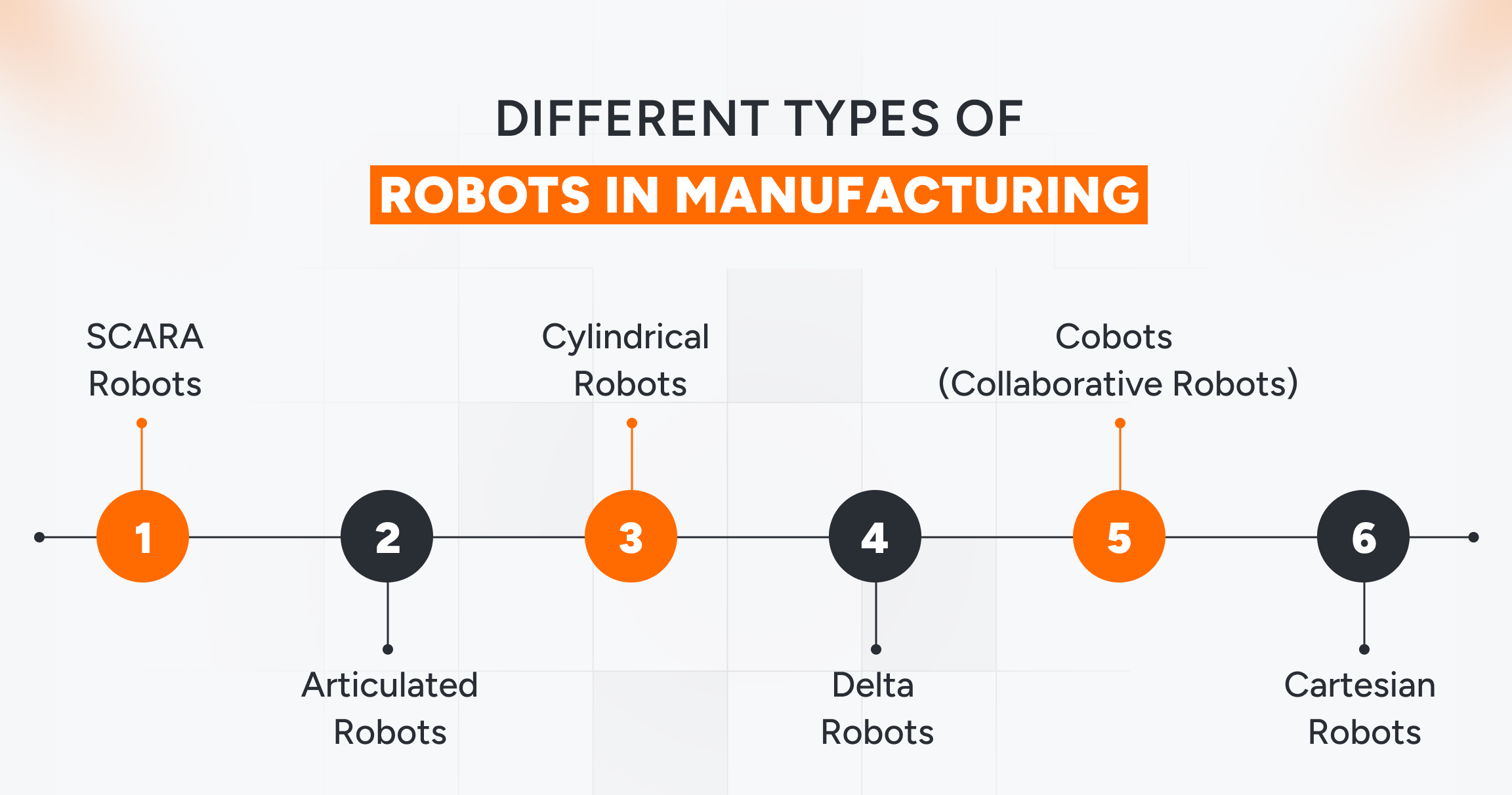

Different Types of Robots in Manufacturing

As robotics in manufacturing evolves, factories are adopting a wide variety of robotic systems. There are different types of robots, each designed to solve specific challenges and optimize different stages of production. From high-speed assembly to precision handling and autonomous mobility, today’s robots bring flexibility, efficiency, and intelligence to every corner of the industrial floor. Understanding these types helps businesses choose the right tools and strengthen their automation strategy, especially as robotic process automation in the manufacturing industry continues to merge digital and physical workflows.

SCARA Robots

SCARA, or Selective Compliance Assembly Robot Arm, features a four-axis design that combines rigidity with controlled flexibility. This makes them extremely fast and accurate, ideal for high-speed pick-and-place tasks in electronics, food, and consumer goods. Their compact footprint and precision often make them the first choice for repetitive micro-assembly work.

Articulated Robots

Articulated robots mimic the movement of a human arm, using 4, 5, or 6 axes to deliver exceptional range and versatility. Whether welding car bodies, picking boxes, painting surfaces, or assembling machinery, these robots form the backbone of automation across almost every industry. Their ability to rotate freely makes them one of the most flexible tools on the factory floor.

Cylindrical Robots

Built with a rotating base and either a single or multiple arm segments, cylindrical robots excel at tasks that require lift-rotate-place motions. They often appear in processes where items move along conveyors or are lifted from one station to another. Their ability to handle repetitive rotational tasks makes them valuable for packaging, handling, and assembly.

Delta Robots

Delta robots feature an iconic triangular, downward-pointing structure, suspended above the workspace. Although not designed for heavy loads, they are unmatched in speed and accuracy for lightweight tasks such as sorting food products, handling pharmaceutical items, and micro-assembly. Their agile movements make them one of the fastest robotic systems available.

Cobots (Collaborative Robots)

Unlike traditional robots that work behind safety fences, cobots are engineered to operate safely beside humans. They’re smaller, slower, and built with collision detection, making them perfect for shared tasks like quality checks, material handling, and guided assembly. Their ease of programming and adaptability also make cobots excellent tools for AI-driven learning workflows.

Mobile Industrial Robots (AGVs & AMRs)

Mobile robots move materials autonomously throughout factories and warehouses. While older AGVs follow fixed routes, today’s AMRs use sensors, cameras, and intelligent mapping to navigate freely and avoid obstacles. They support lean manufacturing by ensuring the right materials reach the right station at the right time.

Cartesian Robots

Also known as linear robots, Cartesian systems operate along X, Y, and Z axes using a rail-based structure. Their linear motion delivers exceptional precision, often reaching 0.01 to 0.1 mm accuracy. These robots are widely used for CNC machining, dispensing, assembly, and pick-and-place operations. They’re easy to customize and reconfigure, although their payload capacity is limited due to their axis-supported structure.

Each of these robot types plays a distinct role in transforming production environments, illustrating how robots in manufacturing are moving beyond simple automation that helps manufacturers create smarter, safer, and more efficient production units built for the future.

Applications of Robotics in Manufacturing

The evolution of robots in manufacturing has completely reshaped how factories operate.

Below are the most impactful and widely adopted applications of robotics across modern manufacturing, each playing a major role in optimizing operations and elevating production quality.

1. Production & Assembly

Robotic arms now wear many hats on the assembly line, such as lifting heavy components, performing repetitive movements, and handling delicate micro-assembly tasks with equal precision.

Examples include robot-guided screw fastening in electronics, adhesive dispensing in automotive manufacturing, and precision alignment for consumer goods. These systems ensure consistent quality while freeing human workers for problem-solving and innovation.

2. Cutting & Welding

Welding and cutting are high-risk, accuracy-sensitive operations, making them ideal candidates for robotic intervention.

Robots handle spot welding, arc welding, laser cutting, and plasma cutting while maintaining consistent weld patterns within milliseconds.

This not only improves quality but also protects workers from burns, UV radiation, and chemical fumes, which are major hazards in traditional welding environments.

3. Material Handling

From loading conveyors to managing hazardous substances, robots reduce the friction in material flow across facilities.

Applications include:

- Automated pick-and-place operations

- AGVs and AMRs transporting raw materials

- Robotic arms sorting, polishing, or painting components

These systems help minimize workplace injuries and accelerate throughput, especially in fast-moving industries like chemicals, packaging, and metals.

4. Palletizing & Packaging

Robots automate tasks like sorting items, stacking them into pallets, sealing boxes, and prepping units for shipment with speed and consistency.

For example, food manufacturers use high-speed palletizing robots to handle fragile items without breakage, while pharmaceutical companies deploy robotic packaging systems for tamper-proof sealing.

5. Machine Tending

Machine tending is one of the more complex and rapidly expanding applications of robotics.

Robots manage tasks such as:

- Loading/unloading CNC machines

- Adjusting machine settings

- Deburring and cleaning components

- Monitoring production cycles

This leads to fewer interruptions, tighter cycle times, and reduced dependency on manual supervision.

6. Quality Inspection & Quality Assurance

Modern robots equipped with advanced vision systems, sensors, and machine learning algorithms can inspect every product with near-zero margin for error.

They detect micro-cracks, dimensional inconsistencies, discolouration, or deviations from tolerance instantly.

Manufacturers in electronics, automotive, and medical devices rely heavily on robotic quality assurance to maintain strict compliance and avoid costly recalls.

7. Painting, Drilling & Finishing Operations

Tasks like painting, drilling, and grinding require extreme consistency, something robots are naturally good at.

- Painting robots ensure uniform coating with minimal overspray.

- Drilling robots deliver precise hole placement at scale.

- Grinding robots maintain consistent pressure for perfect finishes.

These systems drastically reduce material waste while improving product appearance and durability.

8. Sorting & Pick-and-Place

Robots excel at high-speed sorting and pick-and-place tasks based on shape, size, weight, or colour.

For instance, in consumer goods packaging, robots sort hundreds of products per minute, while in electronics, they pick micro-components with sub-millimetre accuracy.

9. Autonomous Transportation Within Facilities

AGVs and AMRs are becoming the backbone of factory logistics. These mobile robots deliver raw materials to workstations, carry finished products to storage areas, and keep production flowing smoothly.

Their ability to self-navigate using cameras, LiDAR, and machine learning creates safer, smarter, and more efficient industrial environments.

10. Material Movement & Safety Handling

In industries involving chemicals, metals, or hazardous environments, robots prevent injuries by taking over dangerous tasks.

They move corrosive materials, handle high-temperature components, or navigate environments unsafe for humans, which helps boost workplace safety dramatically.

These applications highlight how robots in manufacturing are doing much more than automating tasks. From enhanced quality control to faster production cycles and safer workspaces, the benefits of robotics in manufacturing continue to multiply, empowering businesses to innovate and scale.

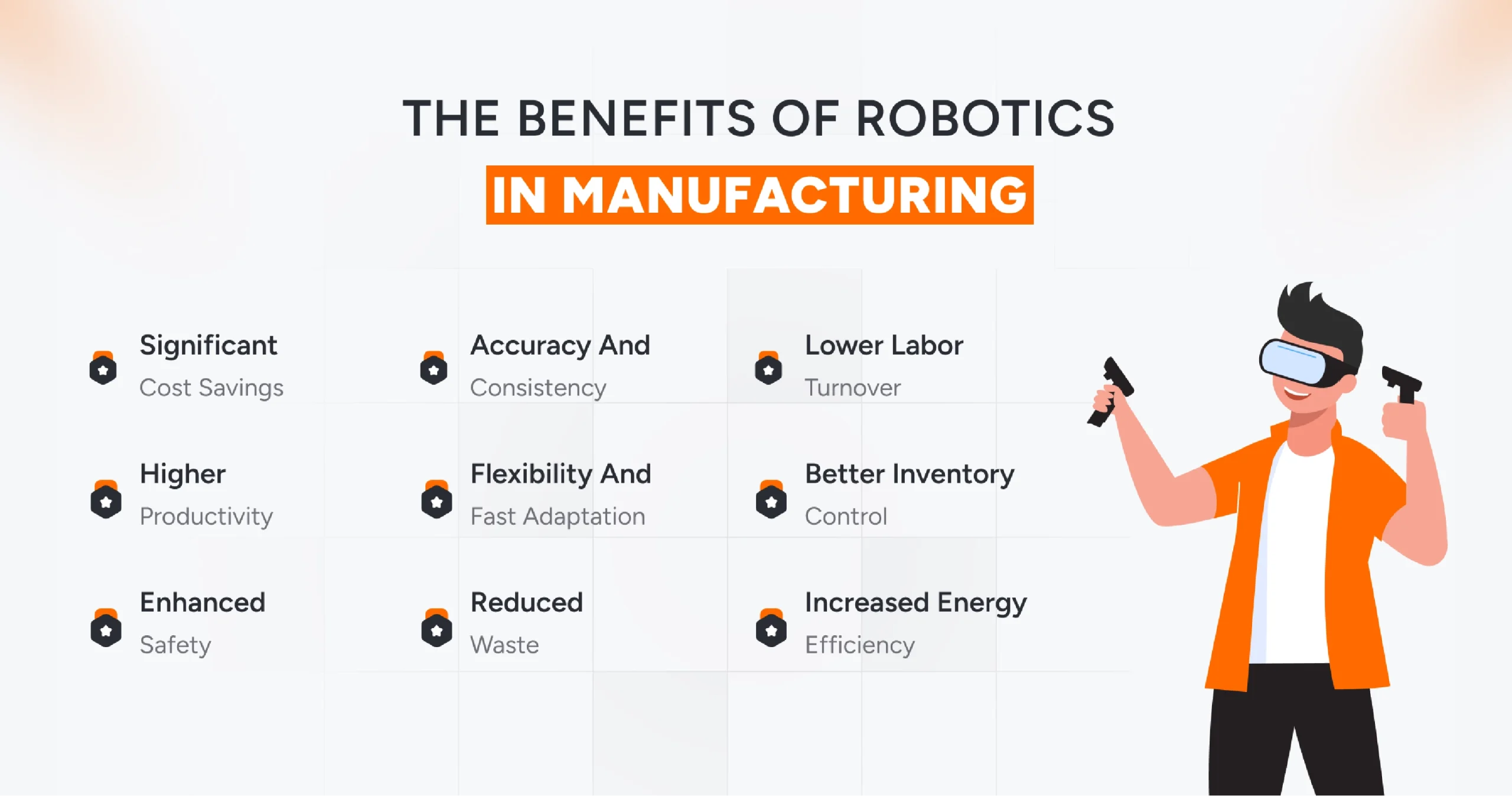

The Benefits of Robotics in Manufacturing

The rise of robots in manufacturing has completely transformed how modern factories compete, scale, and deliver. As more industries adopt intelligent automation and robotic process automation in manufacturing industry workflows, the advantages continue to compound.

1. Significant Cost Savings Over Time

While robots require upfront investment, the long-term savings are undeniable. Automation reduces labor expenses, minimizes rework, prevents production delays, and cuts overhead costs like lighting and heating. With faster cycle times and fewer errors, manufacturers achieve more output using fewer resources.

2. Higher Productivity and Continuous Operation

Robots can operate 24/7 without needing any breaks, completing tasks that would require multiple human shifts. This constant uptime accelerates production cycles, increases daily output, and ensures manufacturers can meet high-volume demands without compromising quality or efficiency.

3. Enhanced Workplace Safety

One of the most immediate benefits of deploying robots is improved safety. Robots handle hazardous tasks with precision, such as high-temperature operations, heavy lifting, chemical handling, and sharp tool interactions. This reduces workplace injuries, protects workers from harmful environments, and ensures compliance with tough safety regulations.

4. Superior Accuracy and Consistent Quality

Robots excel at precision. Their repeatability eliminates common issues caused by fatigue, distractions, or human error. Every weld, cut, placement, or assembly is executed with exact consistency. That leads to fewer defects, higher product reliability, and dramatically improved customer satisfaction.

5. Flexibility and Fast Adaptation to Changing Demands

Modern robotic systems are agile, re-programmable, and easily integrated into new workflows. Whether manufacturers need to switch product variants, scale output, or modify production sequences, robots adapt quickly. This flexibility lets organizations respond to market changes faster and introduce new products with minimal manufacturing downtime.

6. Reduced Waste and Increased Yield

Robots produce more units that meet quality standards on the first attempt, minimizing breakage, rework, scrap, or discarded materials. Manufacturers not only reduce material losses but also increase the overall yield of their production lines, which helps improve margins without increasing costs.

7. Lower Labor Turnover and Relief From Skill Shortages

With highly skilled manual labor becoming harder to recruit, robotics offers a sustainable solution. Once programmed, robots work without constant retraining. They reduce dependency on scarce technical labor and allow human workers to focus on supervision, maintenance, and strategic roles rather than repetitive manual work.

8. Faster Throughput and Better Inventory Control

Robots streamline production lines by reducing downtime, optimizing cycle times, and supporting lean inventory strategies. Faster movement of goods reduces work-in-progress inventory and enables more accurate production planning & scheduling. As a result, manufacturers deliver faster, operate more efficiently, and maintain healthier cash flow.

9. Increased Energy Efficiency and Lower Overheads

Robots allow facilities to operate with reduced lighting, heating, and general overhead requirements. With automated systems performing tasks without needing ideal human working conditions, factories save substantial energy. These savings compound, improving profitability and making operations more sustainable.

As manufacturers embrace advanced automation and smarter workflows, partnering with experts who specialize in IT services for manufacturing can amplify these results and accelerate transformation.

Conclusion

The rapid evolution of robots in manufacturing is the defining advantage that separates future-ready factories from those that fall behind. As production demands rise and competition intensifies, integrating intelligent automation early unlocks the full benefits of robotics in manufacturing, from precision and speed to cost efficiency and safer work environments. AQe Digital helps businesses adopt scalable, high-impact automation strategies powered by cutting-edge robotics and robotic process automation in manufacturing industry workflows. With our expertise, you can modernize operations faster, reduce risks, and accelerate growth. If you’re ready to automate smarter, feel free to contact us to explore the right robotics roadmap for your business.

FAQs

Costs vary widely depending on robot type, workload, and integration complexity, but ROI often appears within 6–24 months due to reduced labor, fewer errors, and higher output.

Yes. Modern robotics systems are modular and scalable, designed to support SMEs with lower upfront investments and strong long-term savings.

Most industrial robots require minimal maintenance thanks to durable components, built-in diagnostics, predictive analytics, and advanced monitoring tools.

Robots track operations with time stamps, precision logs, and automated inspection data, helping manufacturers meet industry and regulatory standards.

Key trends include AI-driven robots, autonomous mobile systems, smarter sensors, digital twins, and human-robot collaboration that further optimize production.