Retailers lose billions of dollars every year due to inefficient inventory management. But what’s causing it? From stockouts that frustrate customers to overstocking that drains cash flow, there are many reasons. These inefficiencies don’t just cut into margins, they drive customers toward competitors who manage their operations better.

The good news is that businesses adopting advanced inventory management software are reversing this trend. Such software helps them with inventory optimization, achieve higher order accuracy, lower carrying costs, and improve customer satisfaction. The challenge isn’t just realizing that inventory management matters, but knowing which solution to choose and how to implement it before inefficiencies become too costly to ignore.

Especially when the inventory management software market is set to reach $7.14 billion by 2033, growing at a CAGR of 8.4%, you need to find the right option. This comprehensive guide, curated by our experts, is designed to assist you with it.

In this guide, we’ll cover:

- What is inventory management software, and why does it matter?

- The difference between inventory control and inventory management

- The top factors to consider when selecting the right inventory management software

By the end, you’ll have a clear roadmap to turning operational challenges into competitive advantages and driving sustained retail growth.

What is Inventory Management Software?

Inventory management software is a system that enables businesses to track, organize, and manage all critical tasks related to inventory control. It centralizes data, helps reduce stockouts through automated retail inventory systems, and provides demand forecasts through real-time reports.

Such software features integrated retail store inventory software that help optimize purchasing activities and ensure real-time reporting for supply chain efficiency.

How Has Inventory Management Software Evolved?

Inventory management software has evolved from a manual, paper-based system to automated cloud-based systems, which are much more sophisticated. This software uses barcodes, RFID, artificial intelligence (AI), and the Internet of Things (IoT) to ensure optimal inventory management.

Here is how it evolved over the years,

- Primitive Systems- In the early days, inventory was tracked manually using ledgers, paper records, and spreadsheets. This method was prone to errors, time-consuming, and unsuitable for growing businesses. Stockouts, overstocking, and lack of visibility were common issues.

- Barcode-Based Tracking- With the introduction of barcode technology in the 1970s and 1980s, businesses started using barcode scanners to track inventory items more accurately. This significantly reduced human error and sped up the process of data entry and stock audits.

- On-Premise Inventory Software- By the 1990s, specialized on-premise inventory management systems were introduced. These provided businesses with digital record-keeping and basic automation features but required heavy infrastructure, upfront licensing costs, and dedicated IT teams for maintenance.

- Cloud-Based Inventory Systems- In the 2000s, cloud technology transformed inventory management. Software-as-a-Service (SaaS) platforms offered real-time visibility, remote access, and integration with accounting, e-commerce, and supply chain systems. Businesses could now scale without worrying about infrastructure or high upfront costs.

- AI, IoT, and RFID-Enabled Solutions- Today’s inventory management solutions are highly intelligent and interconnected. Modern warehouse stock management software use AI for demand forecasting, IoT sensors for real-time tracking, and RFID tags for instant visibility .

What are the Benefits of Using Inventory Management Software?

Implementing inventory management software isn’t just about tracking products—it’s about transforming your entire retail operation into a lean, profitable, and customer-focused business. Modern eCommerce stock management software deliver measurable benefits that directly impact your bottom line while freeing your team to focus on strategic growth initiatives.

1. Increased Operational Efficiency

Gone are the days of endless spreadsheets and manual stock counts. Inventory management software automates time-consuming tasks that once required hours of manual labor. Barcode scanning and RFID integration eliminate data entry errors while speeding up receiving, picking, and cycle counting processes.

In fact, companies using automated inventory systems reduce manual data entry errors by 67% and achieve 99.5% inventory accuracy.

2. Reduction in Stockouts and Overstock

What if you never need to explain to your customer why their favorite product is out of stock, and avoid the cash drain of overstocked items gathering dust in your warehouse?

AI algorithms can analyze purchasing patterns, seasonal trends, and market conditions to predict precisely what you need and when. This allows businesses to improve stock turnover. According to McKinsey, AI can reduce inventory levels by 20–30% by enhancing demand forecasting through machine learning and dynamic segmentation.

3. Improved Cash Flow and Profit Margins

Your inventory is your most significant investment, shouldn’t it work harder for you? Inventory management software optimizes every dollar tied up in stock by ensuring you invest in products that sell, not products that sit.

Reduced carrying costs include eliminating storage fees for excess inventory, lower insurance premiums, and decreased waste from expired or obsolete products. Better demand planning means smaller, more frequent orders that improve cash flow velocity while maintaining service levels.

4. Enhanced Customer Satisfaction

Happy customers drive repeat business and referrals. 99% order accuracy becomes achievable when software eliminates human error in picking and fulfillment. Real-time inventory visibility and an enhanced stock control system mean customers receive accurate product availability information.

Faster fulfillment times result from streamlined warehouse operations and optimized picking routes generated by the software. When customers consistently find what they want and receive it quickly, satisfaction scores and sales soar.

5. Strategic Business Intelligence

You can transform your inventory data into a competitive advantage with advanced AI-based analytics capabilities. It can help you identify most profitable products, understand seasonal buying patterns, and ensure retail inventory control.

Supplier performance metrics reveal which vendors consistently deliver on time, provide high-quality products, and offer the best value. It enables more innovative partnerships and more effective negotiations.

This is why there has been widespread adoption of AI-based inventory management software. In fact, spending on AI-powered supply chain and inventory management software will increase to $55 billion by 2029.

What are the Key Features to Look for in Inventory Management Software?

Inventory management software offers numerous features that retail companies can utilize to streamline their operations. Some of these features are,

1. AI-based Demand Forecasting

Modern systems utilize artificial intelligence and predictive analytics to forecast customer demand, leveraging historical sales data, seasonal trends, and market fluctuations to inform their predictions. This reduces stockouts, minimizes overstocking, and ensures that businesses always have the right products available at the right time.

2. Real-Time Inventory Tracking

With barcode scanning, RFID, and IoT integrations, businesses can track stock levels in real-time across multiple locations, warehouses, stores, and distribution centers. This eliminates discrepancies, improves visibility, and helps maintain accurate stock records.

3. Automated Reordering

Inventory management software can be configured to trigger automated reorders when stock levels hit a predefined threshold and identify key inventory stock days. This ensures uninterrupted product availability while saving procurement teams time and reducing human error.

4. Multi-Channel Integration

For retailers and eCommerce companies, multi-channel integration is crucial. The software should seamlessly synchronize inventory across platforms, including online stores, physical outlets, and marketplaces such as Amazon or Shopify, ensuring consistent availability across all sales channels.

5. Centralized Dashboard & Analytics

A unified dashboard provides a single view of inventory health, sales trends, supplier performance, and stock movement. Customizable reports and analytics empower businesses to make data-driven decisions and optimize supply chain strategies.

6. Supplier & Purchase Order Management

Built-in supplier management tools simplify the creation, approval, and tracking of purchase orders. Businesses can negotiate better deals, monitor vendor performance, and streamline procurement cycles.

7. Batch & Expiry Tracking

For industries such as food, pharmaceuticals, or cosmetics, batch and expiry tracking is critical. Advanced inventory tracking software enables businesses to manage batch numbers, expiration dates, and recalls, ensuring compliance and minimizing waste.

8. Scalability & Cloud Accessibility

Cloud-based solutions provide scalability for growing businesses. They allow remote access, automatic updates, and the flexibility to manage multiple warehouses or global supply chains without heavy infrastructure investments.

Inventory Control vs. Inventory Management: What’s the Difference?

Terms such as inventory control and inventory management are often used interchangeably in the retail industry. However, they represent distinct functions within the broader ecosystem of stock oversight. Understanding the difference is crucial for optimizing efficiency, reducing inventory costs, and ensuring products are always available when customers need them.

What is Inventory Control?

Inventory control focuses on the day-to-day regulation of stock within a business. It ensures that the right products are stored in the right quantities, in the right place, and at the right time. Core activities include tracking stock levels, preventing stockouts or overstocking, monitoring expiration dates, and maintaining product quality.

For example, in retail, inventory control ensures that a store doesn’t run out of fast-moving items while avoiding excess inventory of slow-moving goods. In manufacturing, it involves maintaining a steady supply of raw materials without tying up unnecessary capital. In short, inventory control deals with the accuracy, availability, and cost-efficiency of existing stock.

What is Inventory Management?

Inventory management is a process of managing, ordering, storing, using, and selling a company’s stock. This includes management of raw materials, components, and finished products. Using inventory management software, you can ensure effective handling of raw materials, enhanced pre-processing, and reduce wastage. Inventory management sets the strategic direction, while inventory control ensures that execution is accurate and reliable.

Key functions of inventory management include:

Planning & Forecasting: Predicting customer demand using historical data and AI-based tools.

Supply Chain Integration: Coordinating with suppliers, distributors, and logistics partners.

Automation & Optimization: Leveraging software to automate reordering, streamline workflows, and generate real-time reports.

Financial Oversight: Ensuring that inventory investments align with cash flow, profitability, and business growth.

What is the Difference Between Inventory Control and Inventory Management?

Here are the key differences between inventory control and inventory management,

Which Is More Important for Your Business?

Inventory control and management go hand in hand. Focusing solely on control can ensure stock accuracy but may hinder future demand adaptation. Conversely, prioritizing management without proper control can lead to inaccuracies and disruptions.

For small businesses, effective inventory control is crucial for maintaining efficiency. As companies grow, effective inventory management becomes vital to cope with larger supply chains and customer demands.

Utilizing modern inventory management software is the most effective approach. These systems combine control and management, providing real-time stock visibility, automated reordering, and advanced forecasting capabilities in a single platform.

Now that you know the benefits and features, it’s time to choose an inventory management software for your business. But how to choose the right one?

Top Factors to Consider When Selecting Inventory Management Software

Strategic inventory management software selection is crucial for achieving operational excellence and maintaining a competitive positioning. Organizations that prioritize comprehensive evaluation criteria achieve 30% higher inventory efficiency and measurably superior profit margins.

The decision requires a systematic assessment of critical factors that align with enterprise objectives and operational requirements.

Strategic Integration Requirements

Seamless connectivity across all business systems is non-negotiable. Your solution must integrate with existing POS, e-commerce platforms, and ERP systems through robust APIs and pre-built connectors. Poor integration creates data silos, inventory discrepancies, and operational inefficiencies that directly impact customer satisfaction and competitive advantage.

Customization and Operational Flexibility

Generic solutions limit competitive differentiation. Enterprise-grade platforms offer configurable dashboards, automated workflow engines, and flexible reporting frameworks that adapt to your unique operational requirements. This flexibility enables organizations to maintain established processes while optimizing system performance for specific industry needs.

User Adoption and Training Requirements

Intuitive design determines implementation success. Complex interfaces that require extensive training can create user resistance and delay the realization of ROI. Prioritize mobile accessibility, streamlined navigation, and comprehensive support resources to ensure rapid adoption across all user levels.

Total Cost of Ownership Analysis

Comprehensive financial evaluation extends beyond licensing fees. Assess implementation costs, training expenses, ongoing support, and infrastructure requirements over multi-year periods. Cloud-based solutions typically offer superior cost predictability with automatic updates and scalable pricing models.

Scalability and Future-Proofing

Platform scalability must accommodate business growth without operational disruption. Your selected solution should handle increased transaction volumes, expanded locations, and evolving market requirements while maintaining performance standards. Evaluate vendor development roadmaps and proven scalability track records.

Best Practices for Implementing Inventory Management Software

Successful implementation transforms inventory chaos into operational excellence, but only when executed strategically and effectively. Organizations that follow proven implementation methodologies achieve measurable improvements in deployment efficiency and user satisfaction. These best practices ensure your investment delivers maximum value while minimizing operational disruption.

1. Establish Clear Project Goals and Scope

Define specific, measurable objectives before implementation begins. Document current pain points, establish target KPIs, and create realistic timelines with dedicated budget allocations. Involve key stakeholders from operations, IT, and management to ensure comprehensive requirement gathering and organizational alignment.

🚀 Pro Tip: Create a project charter that includes success metrics like inventory accuracy percentage, order fulfillment speed, and cost reduction targets. This document becomes your north star during challenging implementation phases.

2. Build a Cross-Functional Implementation Team

Assemble dedicated team members with clearly defined roles and responsibilities. Include a project manager, warehouse operations leader, IT specialist, database administrator, and WMS expert. This diverse team ensures technical expertise combines with operational knowledge for optimal system configuration.

🚀 Pro Tip: Designate “super users” from each department who become internal champions and trainers. These individuals accelerate adoption by providing peer-to-peer support and addressing department-specific concerns.

3. Conduct Thorough Data Migration Planning

Clean, accurate data migration determines system effectiveness from day one. Audit existing inventory records, standardize product naming conventions, and eliminate duplicate entries before migration begins. Create comprehensive backup procedures and validate data accuracy throughout the transfer process.

🚀 Pro Tip: Run parallel systems for 2-4 weeks during migration to identify discrepancies and ensure data integrity. This safety net prevents costly errors while building user confidence in the new system.

4. Implement Comprehensive Training Programs

User competency drives adoption success and ROI realization. Develop role-specific training modules that address daily tasks, exception handling, and reporting requirements. Provide hands-on practice sessions with real data scenarios and create quick-reference guides for ongoing support.

🚀 Pro Tip: Record training sessions and create a digital library of tutorials. This resource accelerates onboarding for new employees and serves as refresher training for existing staff.

5. Execute Phased Rollout Strategy

Gradual implementation minimizes risk while allowing system optimization. Start with pilot locations or product categories to identify issues before full deployment. Use feedback from early adopters to refine processes and address concerns before rolling out the organization-wide rollout.

🚀 Pro Tip: Choose your most adaptable team members for the pilot phase. Their positive experience and feedback create momentum for broader organizational acceptance.

6. Establish Continuous Monitoring and Support

Post-implementation support ensures long-term success and continuous improvement. Set up regular performance reviews, maintain vendor support relationships, and create internal helpdesk procedures. Monitor key metrics continuously and make system adjustments based on operational feedback.

🚀 Pro Tip: Schedule monthly “power user” meetings to identify optimization opportunities and share best practices across departments. These sessions maintain momentum and drive continuous improvement.

Top Inventory Management Software You Can Choose For Your Operations

Here’s a refined table featuring some of the top inventory management software solutions, complete with direct links to their official websites.

As you can see all the software options have specific red flags. But with AQe Digital you can avoid these bottlenecks by building a custom solution.

How AQe Digital Helps You Build Advanced Inventory Management Software?

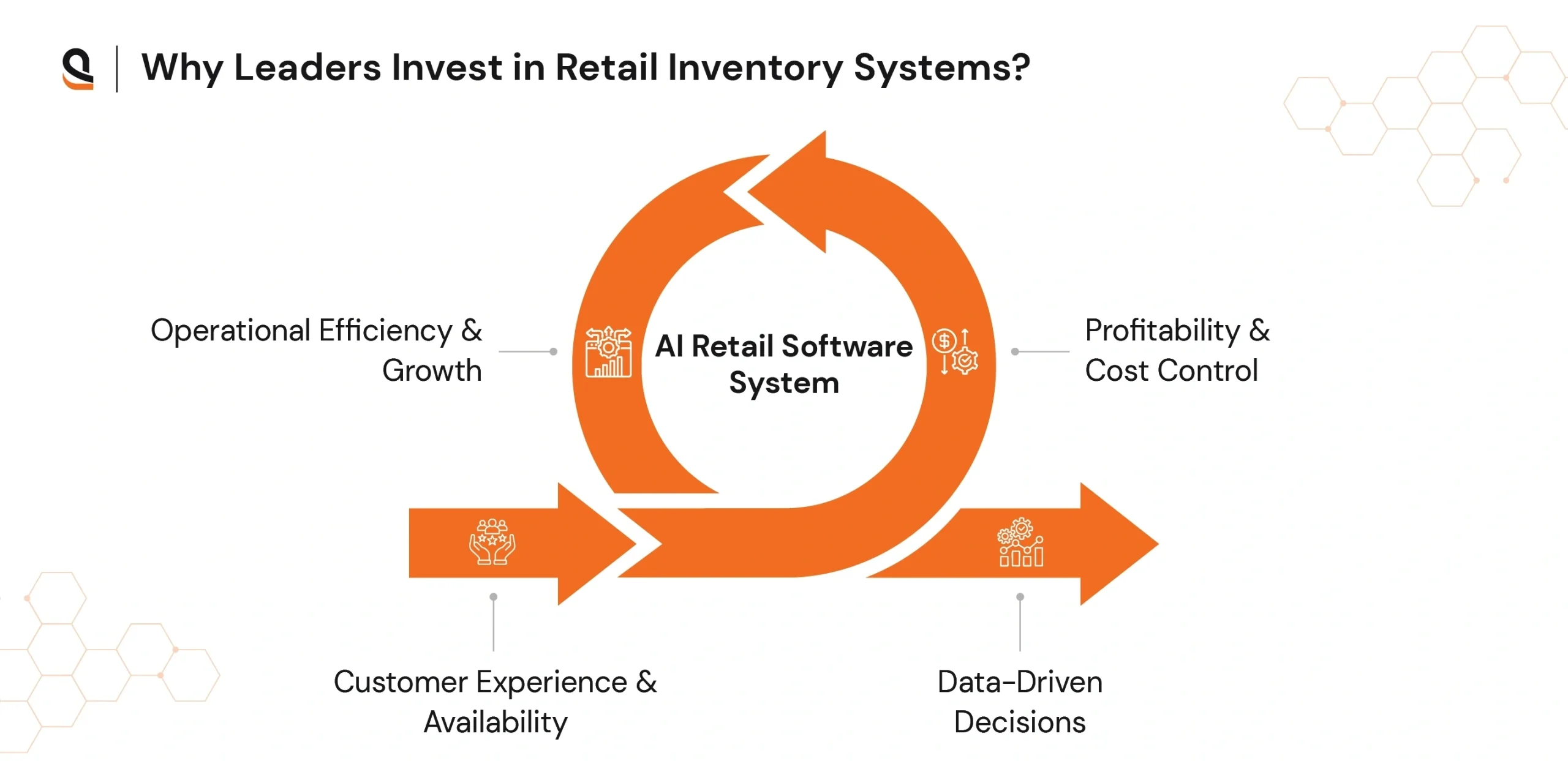

Inefficient inventory management costs retailers billions annually, but the solution lies in adopting the right software. Understanding inventory management and the distinction between inventory control and management is crucial for selecting the right platform.

Data-driven, customer-centric decisions will shape the future of retail. Businesses that stick to outdated systems risk falling behind, while those that embrace advanced solutions will benefit from improved accuracy, efficiency, and resilience.

AQe Digital specializes in designing and implementing tailored inventory management solutions, including AI-powered demand forecasting and real-time analytics. We aim to reduce carrying costs, prevent stockouts, and enhance customer satisfaction. If you’re ready to transform your inventory management, partner with AQe Digital today to future-proof your business.

FAQs

Inventory management software is a digital solution that helps businesses track, manage, and optimize stock across warehouses, stores, and sales channels. It automates processes such as demand forecasting, order management, and stock replenishment, reducing carrying costs and preventing stockouts.

Inventory control focuses on monitoring stock levels, ensuring accuracy, and avoiding losses due to theft or misplacement. Inventory management takes a broader approach, covering the entire lifecycle of products—from procurement and warehousing to forecasting demand and fulfilling customer orders.

Without efficient inventory systems, retailers risk overstocking, stockouts, and higher operational costs. Advanced inventory management software improves order accuracy, enhances customer satisfaction, and ensures better use of working capital.

Key factors include scalability, ease of integration with ERP/POS systems, real-time analytics capabilities, automation features, user-friendly dashboards, vendor support, and overall cost of ownership.

Yes. Most modern inventory management solutions are designed for seamless integration with POS, ERP, and eCommerce platforms, ensuring centralized visibility and eliminating data silos.