Every manufacturing company knows the pain of machines breaking down at the worst possible moment or products failing quality checks after it’s too late.

In fact, unplanned downtime costs the world’s top 500 companies nearly $1.4 trillion each year, with the automotive industry alone losing up to $2.3 million per hour of halted production. You don’t just lose output, you lose resources, time, and customer confidence.

Now imagine if you could see these problems before they happened! This is precisely what predictive analytics in manufacturing can deliver for your business. It turns real-time data into foresight, saving time, money, and reputation.

Let’s understand in detail how predictive analytics is reshaped by manufacturing IT services. Here, you will find the tangible benefits you can capture, along with the practical steps to make them work in your business.

If efficiency, quality, and growth are priorities, this is a read you can’t afford to miss.

Let’s start!

What is Predictive Analytics in Manufacturing?

Predictive analytics in manufacturing is the practice of using historical and real-time data to anticipate equipment failures, quality issues, and production inefficiencies before they happen.

It represents a significant advancement in how companies manage their operations, moving beyond traditional reactive or scheduled approaches to a more proactive and data-driven strategy.

It is an advanced tool for smart manufacturing that utilises data-driven insights to help manufacturers make informed decisions and predict future events.

By analysing historical and real-time data, predictive analytics identifies patterns and forecasts future outcomes, enabling manufacturers to anticipate issues such as equipment failures, quality defects, and supply chain disruptions before they occur.

What Are The Core Building Blocks for Manufacturing Predictive Analytics?

Predictive analytics in manufacturing isn’t built overnight. It relies on three foundational layers – data, intelligence, and integration. Together, these building blocks transform raw machine signals into actionable foresight that drives both technical efficiency and business impact.

Data Collection with Sensors, IoT, and MES

Predictive analytics in manufacturing begins with the collection of vast amounts of high-fidelity data.

Here is how it pans out,

What is collected

- Machines send signals, such as vibration, temperature, sound, and electricity usage, that hint at health and performance.

- This is paired with context like shift, speed, recipe, and recent work orders, so insights make sense.

How it’s captured

- Small devices called sensors are placed on machines and continuously monitor what’s happening.

- These readings travel through standard factory connectors.

Cleaning and syncing

- The data is checked for errors (spikes, gaps, wrong units) so bad readings don’t trigger false alarms.

- Clocks are aligned so events from different machines line up correctly on a timeline.

Storing safely

- Data is stored in two ways: for fast access during live monitoring, and for long-term retention of trends and audits.

- This makes it easy to look back and see what led to issues or improvements.

Keeping it secure

- Connections are encrypted and access is controlled so only the right teams and apps can see machine data.

- This protects both factory operations and customer information.

Why it matters

- Clean, synced, and contextual data enable software to identify early warning signs and suggest actions before breakdowns or defects occur.

- The result is less downtime, lower costs, and better product quality with fewer surprises.

Machine Learning Models for Prediction

Once data is collected, machine learning models analyze it to detect patterns that humans would likely miss. For example, subtle changes in vibration or energy use may indicate a part is nearing failure long before it actually breaks.

ML models used for predictions continuously learn and improve, making predictions more accurate over time. They also adapt to different production environments, ensuring the insights remain relevant as processes evolve.

Integration into Production Workflows

The real value of predictive analytics comes when insights are embedded into day-to-day operations. Integration with existing systems such as MES, ERP, and Computerized Maintenance Management Systems (CMMS) ensures that predictive alerts automatically trigger maintenance schedules, quality checks, or workflow adjustments.

Such a process creates a closed-loop system where data doesn’t just inform leaders but actively drives operational decisions. Seamless integration ensures predictive models don’t operate in isolation but directly influence shop-floor execution. It’s the difference between “knowing a problem exists” and “seeing it solved before it impacts delivery or customers”.

What Are The Top Benefits of Manufacturing Analytics?

Predictive analytics is not just a technical upgrade. It directly impacts efficiency, cost, and competitiveness. Below are the core business outcomes manufacturers achieve with their adoption.

- Reduction of Equipment Downtime and Enhanced Maintenance

- Improvement of Production Efficiency and Optimization

- Enhanced Quality Control and Defect Reduction

- Significant Cost Reductions

- Strengthened Supply Chain Management & Resilience

- Increased Safety & Risk Mitigation

- Sustainability & Energy Efficiency Gains

- Better Sales, Marketing & Workforce Planning

1. Reduction of Equipment Downtime & Smarter Maintenance

- Predictive maintenance (PdM) uses sensor and IoT data to forecast equipment failures before they occur.

- Maintenance can be scheduled proactively, reducing unplanned downtime and avoiding production halts.

- This approach extends the lifespan of machinery, increases reliability, and improves overall equipment uptime.

- For example, if vibration or spindle load data indicates a tool failure, alerts can trigger timely corrective actions, helping avoid missed maintenance schedules, eliminating costly reactive repairs, and reducing unnecessary interventions.

2. Improved Production Efficiency & Process Optimisation

- Manufacturing analytics solutions identify bottlenecks and inefficiencies in production lines.

- By optimising resource allocation and production schedules, manufacturers can boost throughput by 10–30% and labour productivity by 15–30%.

- Predictive forecasting of Overall Equipment Effectiveness (OEE) enables leaders to make timely interventions, reducing days of low performance.

3. Enhanced Quality Control & Defect Reduction

- Predictive quality analytics identifies defect patterns early, preventing quality issues before they impact production.

- Corrective measures can be applied in real-time, such as adjusting temperature or humidity, to reduce waste and rework.

- Consistent product quality strengthens a brand’s reputation and fosters customer trust.

4. Significant Cost Savings

- Predictive analytics reduces operational costs by optimising maintenance schedules, production planning, and inventory management.

- Accurate demand forecasting prevents overproduction, underproduction, and excess inventory.

- Avoiding unexpected breakdowns and recalls directly contributes to higher profit margins.

5. Strengthened Supply Chain Management & Resilience

- Predictive models improve demand forecasting accuracy by up to 85%, helping optimise stock levels and production schedules.

- By monitoring supplier performance and logistics data, manufacturers minimise risks of delays and disruptions.

- These insights enable better resilience to market volatility, geopolitical risks, and changing customer demands.

6. Increased Safety & Risk Mitigation

- By detecting equipment faults early, predictive analytics reduces the risk of accidents and hazardous failures.

- Safer operations lower liability risks while protecting the wellbeing of the workforce.

- Predictive fault diagnosis also contributes to lower insurance costs and stronger compliance standards.

7. Sustainability & Energy Efficiency Gains

- Manufacturing analytics software pinpoints inefficiencies in energy use and waste management.

- Real-time monitoring helps balance energy loads and shift consumption to off-peak times, cutting costs and carbon footprint.

- Proactive detection of over-consuming machines drives greener operations and long-term sustainability goals.

8. Better Sales, Marketing & Workforce Planning

- By analysing customer data, predictive analytics enables better demand forecasting and product-market alignment.

- Sales teams benefit from accurate demand signals, while production aligns with real market needs.

- Workforce analytics predicts skill gaps, helping leaders upskill teams or plan hiring strategies effectively.

Manufacturing analytics solutions are specialized platforms designed to capture, process, and analyze massive volumes of production data. The goal of these platforms is not just reporting historical performance but enabling predictive and prescriptive actions that improve productivity, quality, and cost-efficiency.

Manufacturing analytics software turns raw data into business intelligence by tracking KPIs, detecting anomalies, and forecasting future outcomes. Manufacturers use these platforms to reduce equipment downtime, enhance supply chain agility, and gain a competitive advantage in fast-changing markets.

Types of Manufacturing Analytics Solutions

- On-Premise Software – Installed on local servers for full control and compliance.

Examples: Siemens Opcenter, Rockwell Automation FactoryTalk. - Cloud-Based Manufacturing Analytics Software – Scalable and cost-efficient, enabling real-time data analytics, IoT connectivity, and MES integration.

Examples: PTC ThingWorx, Microsoft Azure IoT, GE Predix. - Predictive Maintenance Platforms – Use predictive analytics in manufacturing to forecast failures and reduce downtime.

Examples: IBM Maximo, Augury, SparkCognition. - Production Optimization Tools – Improve OEE by identifying inefficiencies, optimizing schedules, and reducing waste.

Examples: AspenTech, Tulip, Plex Systems.

Choosing the Right Manufacturing Analytics Software

The right choice of a manufacturing analytics software depends on your existing infrastructure, growth goals, and whether agility or control is the top priority. When selecting a solution, manufacturers should focus on:

Cost & Scalability: Cloud-based options like Microsoft Azure IoT or GE Predix are ideal for scalability and lower upfront costs. On-premise systems like Siemens Opcenter suit companies needing strict compliance and control.

Integration with IoT/MES: Tools like PTC ThingWorx or Rockwell FactoryTalk integrate seamlessly with IoT devices and MES platforms, enabling real-time insights.

Use Case Alignment:

- For predictive maintenance: IBM Maximo or Augury.

- For production optimization: AspenTech or Tulip.

- For end-to-end operations: Plex Systems as a cloud-native manufacturing analytics solution.

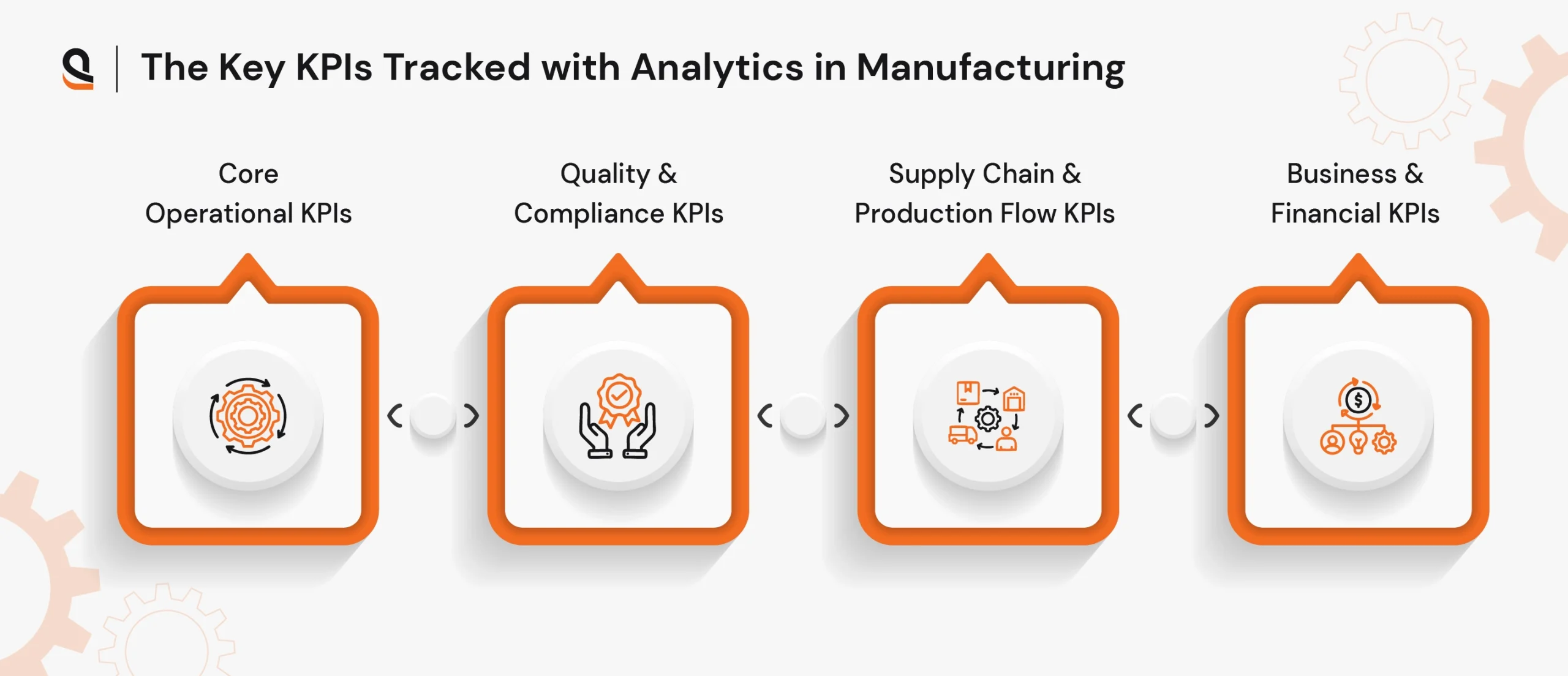

Which Are The Key KPIs Tracked with Analytics in Manufacturing?

Manufacturing analytics becomes truly powerful when it translates raw data into measurable business outcomes. By tracking specific KPIs, leaders and decision-makers gain visibility into production performance, equipment health, and financial impact. These KPIs help technical experts optimize operations while giving executives clear evidence of ROI and competitive advantage.

1. Core Operational KPIs

Operational KPIs measure how well equipment and processes are running on the shop floor. This includes:

Overall Equipment Effectiveness (OEE)

- OEE combines availability, performance, and quality into a single percentage. It highlights how much of the plant’s capacity is being fully utilized.

- A higher OEE means improved productivity without additional capital investments.

MTBF & MTTR

- MTBF [Mean Time Between Failures] measures reliability, while MTTR [Mean Time To Repair] reflects the responsiveness of repair processes.

- Predictive analytics can forecast likely failure points, reducing both manufacturing downtime and repair costs.

Unplanned Downtime Rate

- Manufacturers can track unexpected stoppages and their duration by measuring the unplanned downtime rate.

- By identifying recurring causes, manufacturers can prevent disruptions, safeguard delivery timelines, and reduce maintenance expenses.

2. Quality & Compliance KPIs

Quality indicators ensure that production meets standards while minimizing waste. This will include:

First Pass Yield (FPY)

- FPY measures how many products pass inspection without rework.

- A higher FPY directly lowers production costs and shortens cycle time, making the plant more competitive.

Scrap & Rework Rate

- This highlights material losses and inefficiencies in the production process.

- Reducing these rates boosts margins and ensures better utilization of raw materials.

Defect Rate & Predictive Quality Indicators

- By analyzing process parameters, predictive models detect quality deviations early.

- This prevents large batches of defective products, cutting warranty costs and safeguarding customer trust.

3. Supply Chain & Production Flow KPIs

The KPIs for production flow track the efficiency with which raw materials and finished goods move through production. The main parameters will include:

Cycle Time & Throughput

- Cycle time reflects how long it takes to produce a finished product, while throughput measures overall production output.

- Analytics helps identify bottlenecks and streamline flow, maximizing plant capacity.

Inventory Turnover & Stockouts

- Tracking material usage and availability ensures resources are managed efficiently.

- High turnover indicates efficient supply use, while reduced stockouts keep production continuous and customers satisfied.

On-Time Delivery (OTD)

- OTD tracks whether orders are fulfilled within promised timelines.

- For manufacturing business leaders, strong OTD performance translates into customer loyalty and better market reputation.

4. Business & Financial KPIs

Financial KPIs translate operational efficiency into bottom-line impact. These will include:

Cost of Poor Quality (CoPQ)

- This includes costs from defects, scrap, rework, and warranty claims.

- Analytics helps reduce CoPQ by proactively managing risks in the production process.

Maintenance Cost per Unit Produced

- This measures the amount spent on upkeep relative to output.

- Predictive maintenance lowers these costs by shifting from reactive repairs to planned interventions.

ROI on Analytics Initiatives

- Beyond operations, leaders want proof of value.

- ROI measures the impact of predictive analytics on profitability through cost savings, reduced downtime, and more efficient use of assets.

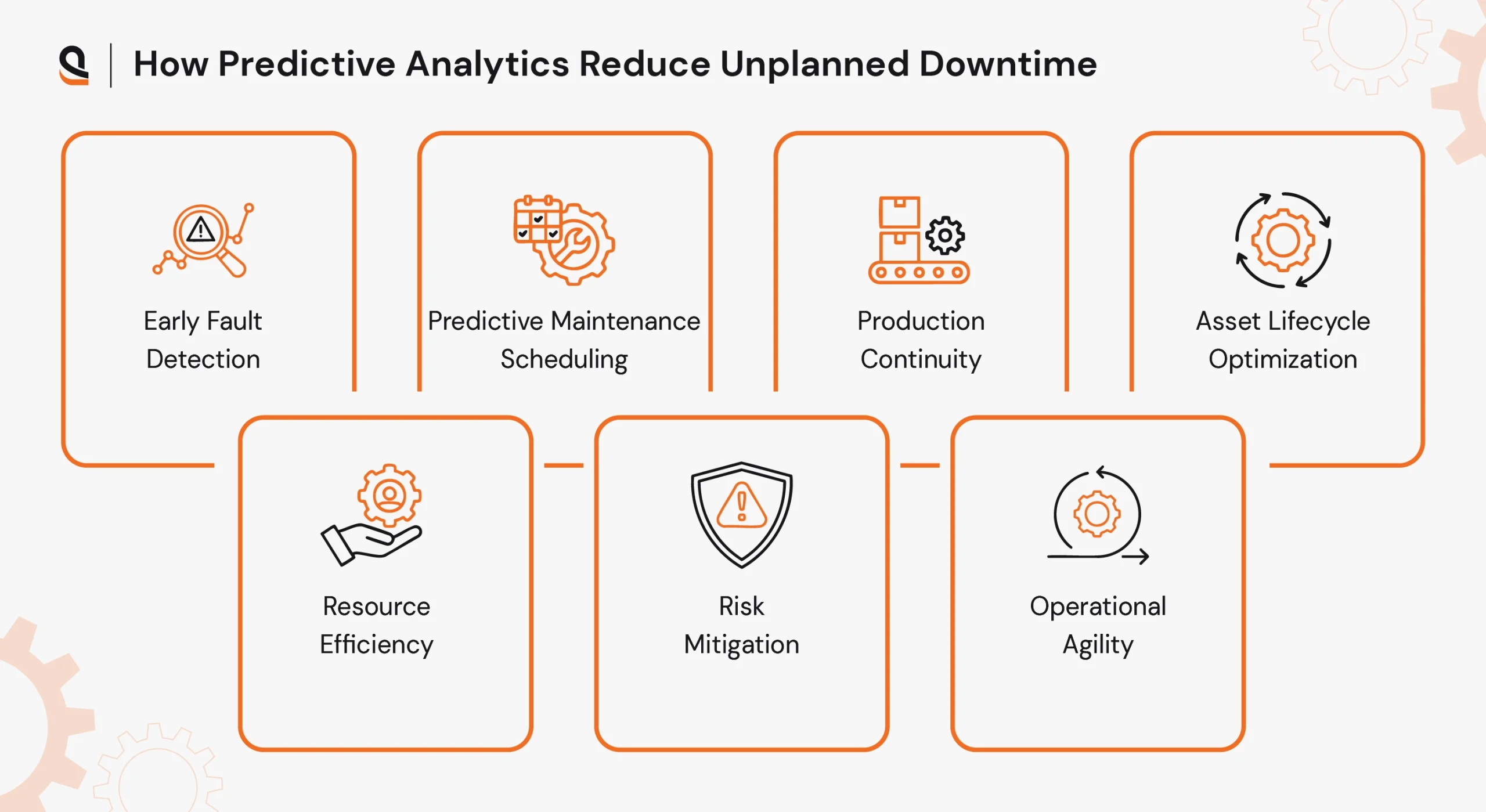

How to Reduce Unplanned Downtime through Data Analytics in Manufacturing?

Predictive analytics enables manufacturers to anticipate equipment issues and take action before they disrupt production. It turns real-time sensor and MES data into actionable insights, helping teams maintain continuous operations and optimize resources. Here’s how it delivers real-world impact:

Early Fault Detection

Continuously monitors machines for unusual vibrations, temperature spikes, or pressure changes. By identifying deviations early, maintenance can intervene before a line stops, preventing costly downtime.

Predictive Maintenance Scheduling

Plans maintenance based on actual machine health rather than fixed schedules. This reduces unnecessary repairs while ensuring interventions occur before failures, keeping production flowing smoothly.

Production Continuity

Minimizes unplanned stoppages and ensures throughput and delivery targets are met. By anticipating potential failures, teams can adjust workflows or shift workloads without impacting timelines.

Asset Lifecycle Optimization

Tracks equipment performance across its lifespan to determine the right time for repairs, part replacements, or upgrades. This maximizes ROI and avoids premature asset replacement.

Resource Efficiency

Allocates labor, spare parts, and energy efficiently based on predicted needs. Resources are available when required, avoiding idle time and reducing operational costs.

Risk Mitigation

Detects potential safety hazards and operational risks early. By addressing equipment issues proactively, companies reduce accidents, regulatory breaches, and unplanned losses.

Operational Agility

Provides real-time insights for quick, informed decision-making. Teams can respond effectively to production fluctuations, supply chain disruptions, or unexpected machine behavior, maintaining operational flexibility.

The improvements discussed here are part of the broader advantages detailed in 7 key advantages of manufacturing data analytics for growth, emphasizing analytics as a growth driver for manufacturers.

What Are The Challenges in Integrating Predictive Analytics?

Adopting predictive analytics in manufacturing can transform operations, but the journey is not without its hurdles. Understanding these challenges helps leaders appreciate the complexity and why expert guidance is essential.

Data Quality Issues

- Predictive models rely on accurate, complete, and consistent data.

- Inconsistent sensor readings, missing MES entries, or fragmented IoT data can undermine predictions.

- Without proper preprocessing, insights may be misleading, which results in poor maintenance or production decisions.

Integration Complexity

- Manufacturing environments often involve multiple legacy systems, MES platforms, ERP software, and IoT devices.

- Seamlessly connecting these systems with analytics platforms requires deep technical expertise and careful planning.

- Integration errors can result in incomplete data streams, delayed alerts, or operational disruptions.

Skills Gap and Training

- Advanced analytics, machine learning models, and IoT integration in manufacturing demand specialized skills.

- Teams may lack experience in building predictive models, interpreting insights, or embedding them into workflows.

- Without proper training, even the best analytics software may fail to deliver tangible results.

Evaluating Vendor Support and ROI

- Non-technical executives must assess whether a vendor can provide end-to-end implementation, ongoing support, and measurable business outcomes.

- Key considerations include scalability, cost, integration ease, and the ability to generate actionable insights that improve efficiency, reduce downtime, and enhance quality.

AQe Digital Helps Make Manufacturing Analytics Simple

Predictive analytics in manufacturing is not plug-and-play. Attempting to implement it without expertise can lead to wasted resources, missed opportunities, and limited ROI. Partnering with experts like AQe Digital ensures:

- Seamless integration with existing systems.

- Accurate, high-quality data for reliable insights.

- Knowledge transfer and training for internal teams.

- Clear alignment with business goals and measurable returns.

Our case study on transforming chemical manufacturing with AI & Data analytics clearly illustrates how data-driven strategies improve reliability and support smarter decision-making in manufacturing.

In a Nutshell:

Predictive analytics is changing the way manufacturers run their operations. It helps spot issues before they become problems, keeps production moving, and improves efficiency across the plant.

Although implementing data analytics isn’t simple, data quality, system integration, and specialized skills are critical for success. Engaging with experienced data analytics consulting services drives measurable results.

For business leaders and technical teams alike, adopting predictive analytics means making more informed decisions, minimizing downtime, and staying ahead in a competitive market.

FAQs

Manufacturing analytics is the use of data from machines, MES, IoT sensors, and business systems to monitor, predict, and optimize production performance, quality, and cost.

Predictive analytics analyzes historical and real-time signals (vibration, temperature, energy, process parameters) to forecast failures, defects, and bottlenecks so teams can act before issues impact output.

It reduces unplanned downtime, scrap, and rework, improves OEE and throughput, stabilizes quality, optimizes maintenance, and strengthens supply chain planning.

Sensor/IoT telemetry (vibration, temperature, current), MES events (orders, shifts, recipes), quality data (inspection, FPY), ERP data (work orders, inventory), and maintenance logs (CMMS).

MES/SCADA run and visualize operations; BI reports history. Manufacturing analytics adds predictive and prescriptive intelligence that automates alerts, recommendations, and optimized actions.