Manufacturing is a complex process with multiple tasks happening simultaneously across departments, systems, and resources. To streamline workflows and ensure operational excellence, manufacturers need real time monitoring, production line monitoring, and in-depth visibility into every facet of the process. Implementing smart factory solutions with cloud computing in manufacturing and IoT in manufacturing industry is the key to transforming traditional operations into intelligent, connected systems.

Production units lacking real time monitoring systems face extended downtime, ineffective inventory management, poor resource utilization, inaccurate demand forecasting, and other challenges. To address all these challenges, businesses need to have manufacturing data analytics and IoT solutions for manufacturing, empowered with cloud computing, to enable smart factory automation.

Having cloud and IoT solutions for manufacturing helps manufacturers keep track of everything in real-time, from equipment performance to worker activity, with continuous monitoring. Manufacturers need to integrate IoT solutions in manufacturing to automate workflows and extract actionable insights from across the network of machines and production lines.

Understanding Real-Time Monitoring For Smart Manufacturing Solutions

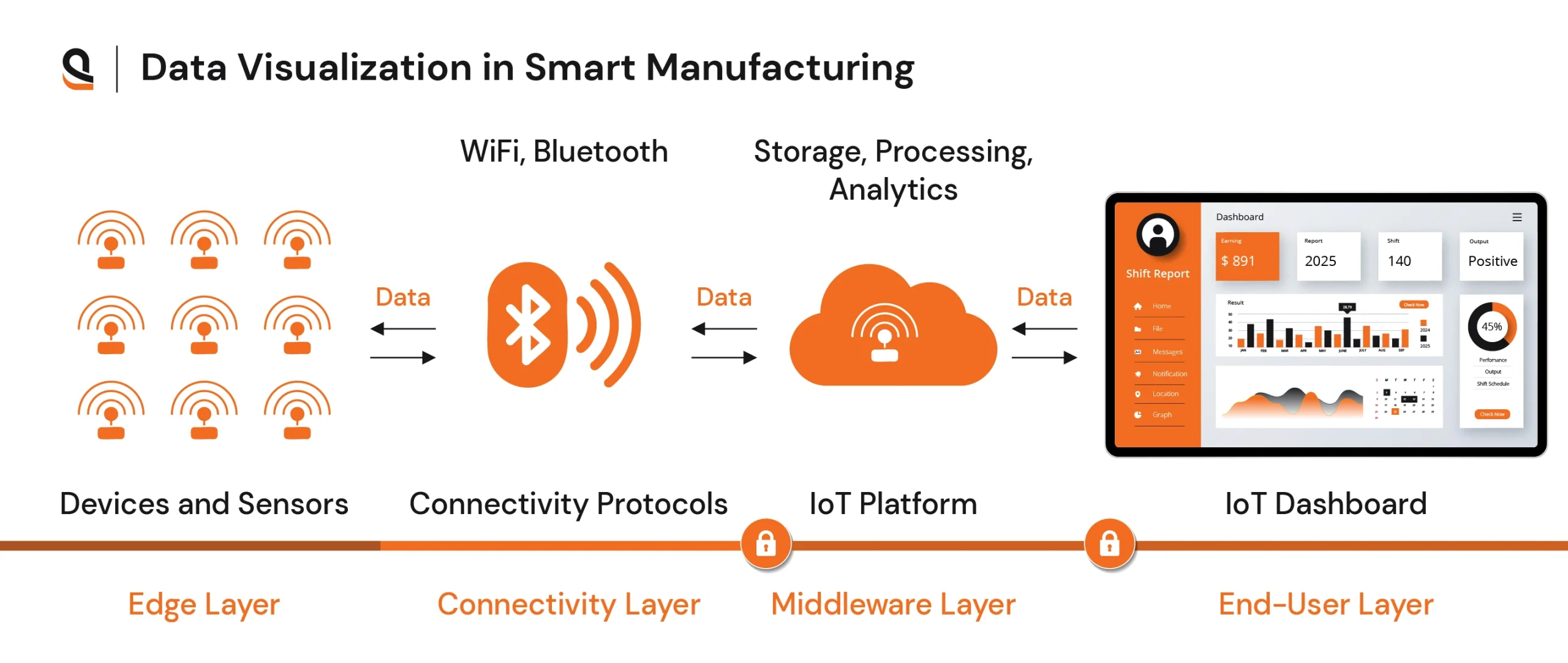

Cloud for manufacturing and IoT-integrated production monitoring helps collect data from the sensors and store it securely in the cloud. This network helps in tracking equipment usage, performance, and maintenance. AI-based data analytics analyzes the vast amount of data, providing actionable insights that enable manufacturers to make well-informed decisions and gain in-depth visibility into the entire production process.

Production environments without real time monitoring and production line monitoring are vulnerable to extended downtime, inefficient inventory use, missed maintenance opportunities, and inaccurate forecasting. These challenges slow productivity and increase costs. To address them, businesses must adopt manufacturing monitoring solutions built on IoT in manufacturing industry and powered by cloud computing in manufacturing.

From maintaining manufacturing conditions like temperature and humidity to reducing unplanned downtime and production delays, having cloud-led IoT solutions in manufacturing in place for production monitoring ensures smooth workflows, better quality, and cost-saving with less product spoilage and damage. With production process monitoring devices, manufacturers can track everything in real time—from equipment status to worker performance.

What is Real Time Monitoring in Smart Manufacturing?

Real time monitoring in smart manufacturing integrates IoT in manufacturing industry with cloud computing in manufacturing to create an intelligent system of sensors and analytics platforms. These systems collect, transmit, and store production data, giving decision-makers full visibility of the manufacturing floor.

AI-powered manufacturing monitoring platforms analyze this data, detecting anomalies and offering actionable insights. This deep understanding allows for early defect detection, optimized resource use, and streamlined operations.

The integration of production process monitoring devices provides a continuous feedback loop on temperature, humidity, equipment health, and operator performance, ensuring every factor that affects productivity is under observation.

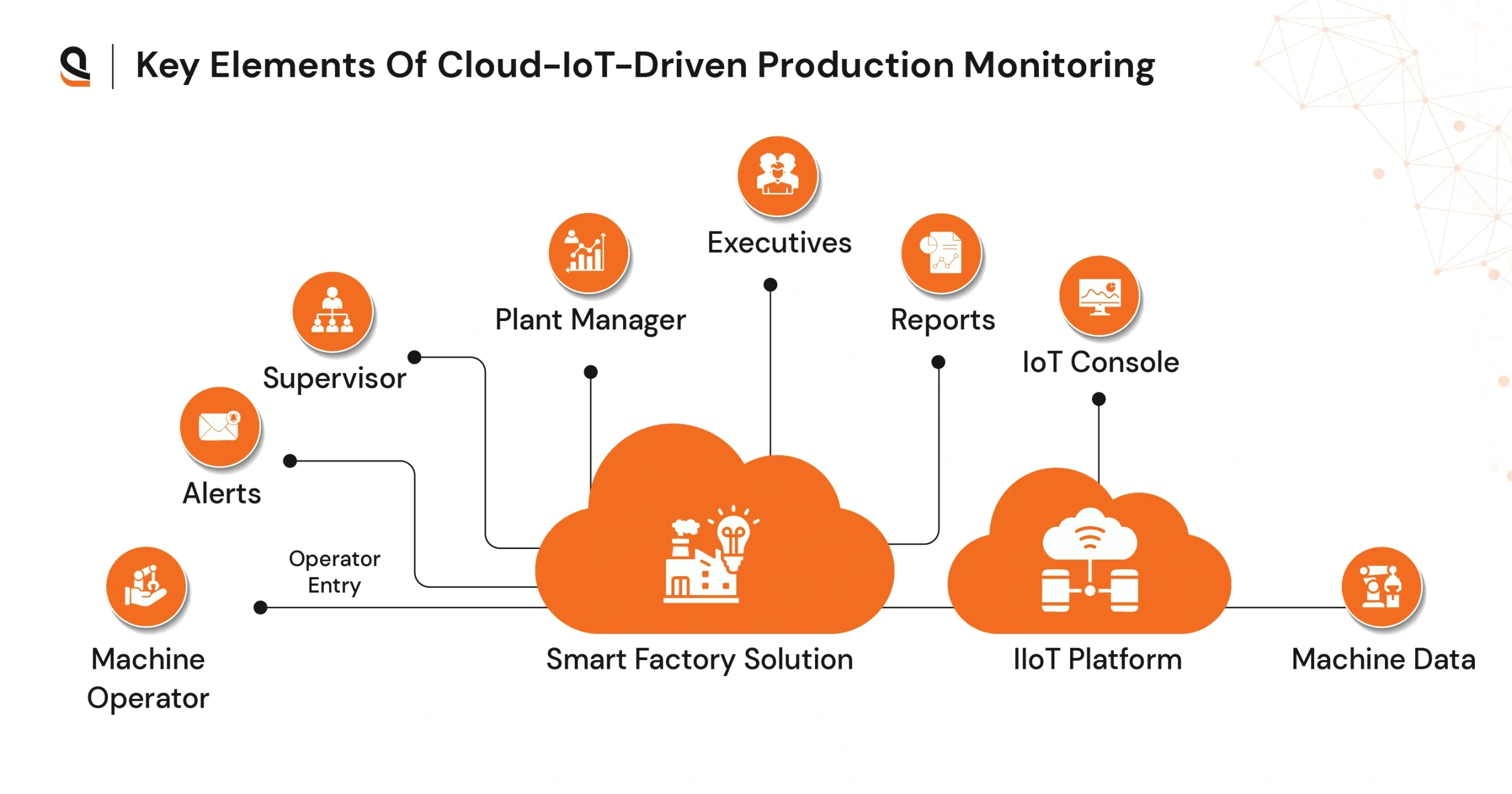

Key Elements Of Smart Production Monitoring System

To enable well-connected, efficient, and smart factory automation powered by cloud and IoT, it consists of the following key components:

- IoT: Gathers data and connects the devices in the manufacturing process, enabling production line monitoring.

- Data processing and analytics: A platform that transforms raw and unstructured data into actionable insights.

- Dashboard: Helps stakeholders visualize complex data in a simple form from manufacturing monitoring systems.

- Cloud: Provides scalable data storage and processing capabilities with easy access.

- Production Process Monitoring Devices: Collect real-time operational data to track efficiency.

Significant Impact Of Cloud and IoT in Manufacturing Industry:

Better ROI: As per the reports by McKinsey, manufacturing has the potential to create an economic impact of $1.2 to $3.7 trillion per year by 2025 with the application of IoT solutions.

Reduced Breakdown: The research by Deloitte indicates manufacturers can reduce equipment breakdown by 70% and decrease maintenance costs by 25% with the predictive maintenance enabled by IoT technologies.

The above stats indicate the importance and significant impact of IoT and cloud for manufacturing. You need a reliable and experienced digital solution provider to integrate IoT and cloud-related services to make your manufacturing efficient, smart, and streamlined.

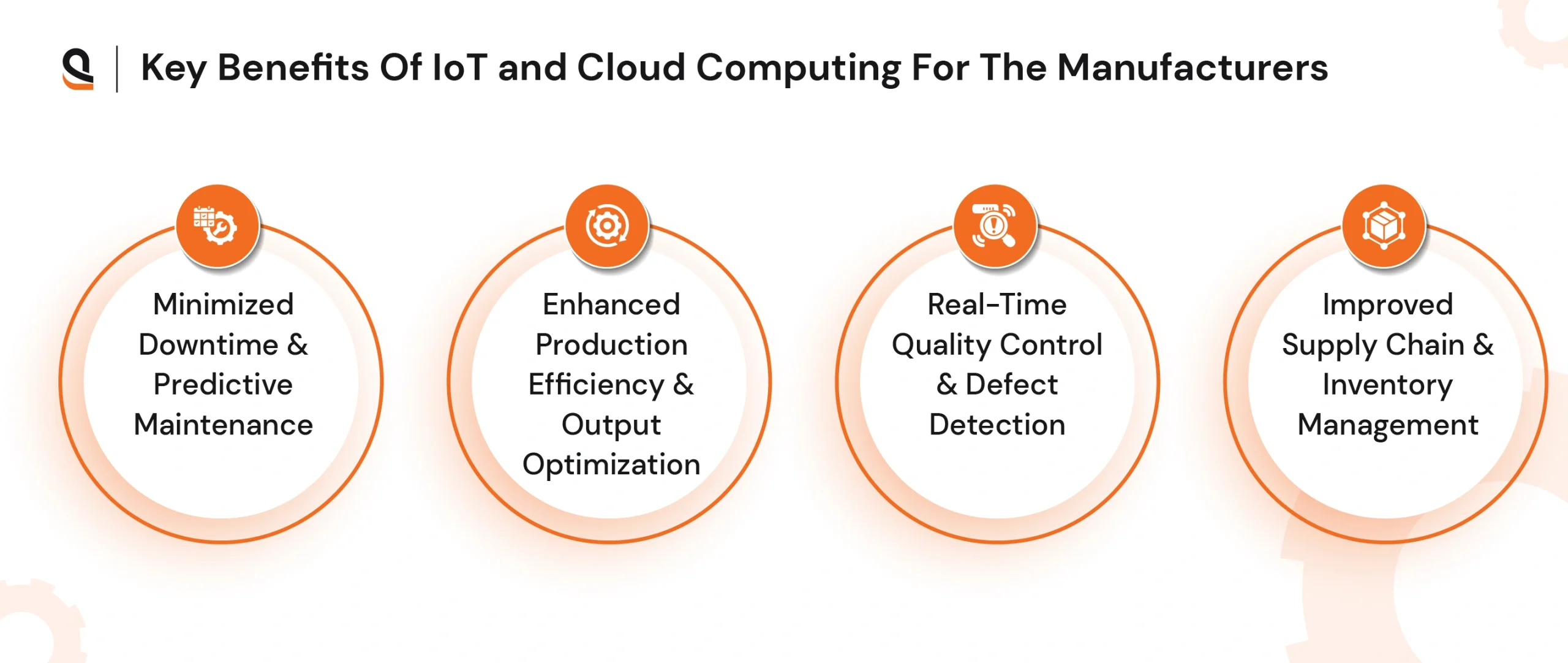

Top Benefits of Integrating IoT and Cloud in Manufacturing

By leveraging IoT and cloud-led production monitoring, manufacturers can gain deeper insights, optimize operations, and enhance overall efficiency with manufacturing data analytics. Let’s explore the key benefits in detail:

Minimized Downtime & Predictive Maintenance

The Challenge: One of the major concerns for manufacturers is unplanned downtime, as it halts production, leading to resource wastage and time. Lack of predictive analytics in manufacturing results in unexpected equipment failure, leading to significant downtime, costly repairs, and revenue loss. The absence of AI-powered predictive maintenance results in a failure to prevent such disruptions.

Our Solution: We help you integrate IoT solutions in manufacturing to continuously monitor machinery health, which helps detect any unusual behaviour or signs of wear and tear. Our team helps you have a cloud for manufacturing and IoT-enabled production monitoring to forecast potential failures for predictive maintenance. It helps manufacturers schedule maintenance and plan the production process more effectively with better resource allocation. With the help of AI and production process monitoring devices, manufacturers can detect signs of wear and tear, allowing for proactive maintenance.

Key Benefits:

- Prevention of costly and unplanned breakdowns

- Optimized maintenance schedules

- Enhanced operational efficiency

Enhanced Production Efficiency & Output Optimization

The Challenge: Poor cross-departmental collaboration, data silos, inaccurate workflows, and inefficient resource utilization lowers the productivity of the production lines. Lack of manufacturing data analytics results in the inability to analyze data accurately, making manufacturers struggle to identify problem areas and make data-driven decisions.

Our Solution: We integrate manufacturing data analytics and dashboards to visualize actionable insights at every stage of the production cycle. Our AI-driven analytics detect inefficiencies, highlight bottlenecks, and optimize machine performance. With cloud-based solutions and IoT in the manufacturing industry, we collect and store the data to identify hidden patterns and store it securely. Production line monitoring helps identify inefficiencies and resource misallocations in real time. Manufacturing monitoring through smart dashboards allows plant managers to monitor workflows and adjust operations on the go.

Key Benefits:

- Identifying and eliminating bottlenecks

- Optimized machine performance

- Reduced idle time

Download the Ultimate Guide to Solving Data Challenges in Manufacturing

Send download link to:

Real-Time Quality Control & Defect Detection

The Challenge: Manufacturers can’t bear rework and product rejection- it incurs financial and reputational damage to the manufacturers. Defective products result in increased wastage of time, money, and resources. Relying on traditional quality checks fails to catch defects early because they are often conducted post-production.

Our Solution: With cloud-based IoT in the manufacturing industry and real-time monitoring, we can help you identify any defects in the early stage and maintain product quality. Integration of AI-driven computer vision and IoT-based sensors helps monitor product quality at every stage. With production process monitoring devices, manufacturers can detect defects during production using computer vision and AI analytics.

Key Benefits:

- Reduced material waste

- Ensured consistent product quality

- Minimized rework expenses

Improved Supply Chain & Inventory Management

The Challenge: Poor visibility into inventory levels leads to overstocking, stockouts, and supply chain inefficiencies. Without real-time data, manufacturers struggle to balance supply and demand, resulting in excess costs or production delays.

Our Solution: Integration of IoT sensors and smart tracking systems provides real-time inventory visibility across the supply chain, and we help you analyze that data accurately with our comprehensive data analytics solution. Integration of IoT in supply chain management optimizes procurement strategies, ensuring that materials and components are available exactly when needed, reducing both excess inventory costs and the risk of shortages. Real time monitoring of inventory through IoT in manufacturing industry helps optimize procurement, forecast accurately, and avoid stock-related disruptions.

Key Benefits:

- Lower storage costs

- Prevention of stockouts or overstock

- Improved supplier collaboration

How Real Time Monitoring & Cloud Computing Enable Smart Manufacturing?

1. Data Collection and Real time Monitoring:

IoT Sensors:

IoT devices are deployed throughout the manufacturing ecosystem to collect data on various parameters. Production line monitoring begins with sensor deployment across machinery, raw materials, and labor workflows. These production process monitoring devices collect data on speed, quality, and performance.

Real-time Data:

The gathered real-time data is transmitted to the cloud, allowing for continuous monitoring of processes and equipment.

Visibility:

The updated and accurate data provides manufacturers with full visibility of their assets, processes, resources, and products. Manufacturers can make informed decisions leveraging the data gathered, integrating IoT solutions for manufacturing.

2. Cloud Computing for Processing and Analysis:

Data Storage and Processing:

Cloud for manufacturing provides the infrastructure for storing and processing the massive amounts of data generated by IoT devices and other tools. Data is processed and analyzed through cloud computing in manufacturing, enabling remote access and intelligent decision-making.

Advanced Analytics:

Cloud-based analytics can identify patterns, anomalies, and trends in the data. It enables manufacturers to optimize processes, reduce downtime, improve quality, and predict potential problems as well as demand with IoT in supply chain management.

Predictive Maintenance:

By analyzing historical and real-time data, manufacturers can predict equipment failures and schedule maintenance proactively, reducing unplanned/planned downtime and costs.

Remote Real time Monitoring and Control:

Cloud for manufacturing enables remote monitoring and control of production processes, allowing manufacturers to adjust and troubleshoot issues from anywhere.

How Does AQe Digital Help Overcome IoT and Cloud Implementation Challenges?

At AQe Digital, we support clients in overcoming challenges in adopting real time monitoring, production line monitoring, and other digital integrations. We help clients by:

Simplifying IoT Integration: Our team helps manufacturers have seamless connectivity between existing machines, legacy IT infrastructure, and newly integrated IoT networks, ensuring smooth integration.

Addressing Data Overload & Management: Our experienced data and cloud experts enable manufacturers to process vast amounts of IoT data accurately, securely, and instantly.

Ensuring Cyber-security & Compliance: Our team prioritizes security and compliance by implementing robust security measures, including encryption, access controls, and compliance adherence.

Optimizing Costs & Scalability: We offer tailored cloud-IoT solutions that scale based on evolving business needs and challenges.

Providing Support & Training: Our expert team assists in implementation, training, and ongoing maintenance to ensure long-term success.

Why is AQe Digital the Preferred IoT and Cloud Solution Provider For Manufacturers?

At AQe Digital, we provide end-to-end cloud consulting services that help manufacturers from around the globe with:

- End-to-End Digital Transformation: We enable manufacturers to transition from traditional monitoring to a real-time cloud-based system.

- Real-Time Production Insights: Our cloud-enabled IoT solutions provide live dashboards for monitoring equipment performance, quality, and process efficiency.

- Seamless Cloud Connectivity: Our solutions integrate with cloud platforms to store, process, and analyze large-scale manufacturing data securely.

- IoT-Enabled Digital Twin Technology: We create digital replicas of manufacturing operations to simulate, analyze, and optimize production.

- Flexible Deployment Models: Whether on-premise, cloud-based, or hybrid, our solutions adapt to the unique needs of each manufacturer.

Conclusion

To stay competitive, manufacturers must embrace real time monitoring, production line monitoring, and data-led decision-making. By combining IoT in manufacturing industry technologies with cloud computing in manufacturing, businesses can gain unmatched visibility, reduce costs, and improve operational agility. AI algorithms combined with manufacturing monitoring systems detect trends and anomalies, helping manufacturers refine production parameters and enhance product consistency.

At AQe Digital- digital transformation partner, we empower manufacturers with end-to-end solutions, from implementing production process monitoring devices to enabling predictive maintenance and AI-led analytics. Contact us to digitally transform your manufacturing process, leveraging our 27+ years of experience and expertise.