In the world of large-scale engineering, where infrastructure spans continents, timelines stretch across decades, and costs run into billions, the success of engineering companies depends on one critical factor: engineering data management (EDM). The ability to collect, organize, and leverage data efficiently determines not only project performance but also long-term sustainability. This is where engineering data management software and systems become a strategic driver of both environmental and financial outcomes.

Modern organizations are realizing that true sustainability extends beyond ecological impact. It includes sustained revenue, reduced risk, operational efficiency, and lifecycle profitability. With the right engineering data management system in place, engineering firms can unlock the full potential of data to ensure that sustainability goals align with business success.

In this piece of information, we are discussing how engineering data management empowers sustainable practices in large-scale projects and what engineering data management.

What Is Engineering Data Management—and Why Is It Crucial for Sustainable Growth?

Let’s begin with a clear understanding of what engineering data management is. Engineering data management (EDM) is the discipline of organizing, storing, and managing engineering data. This includes 2D/3D models, simulations, materials data, specifications, test results, compliance documentation, and more.

But why is it so vital for sustainability, especially in large-scale projects? As per the report, it is estimated that businesses collectively lose USD 3.1 trillion annually in the U.S. due to bad data.

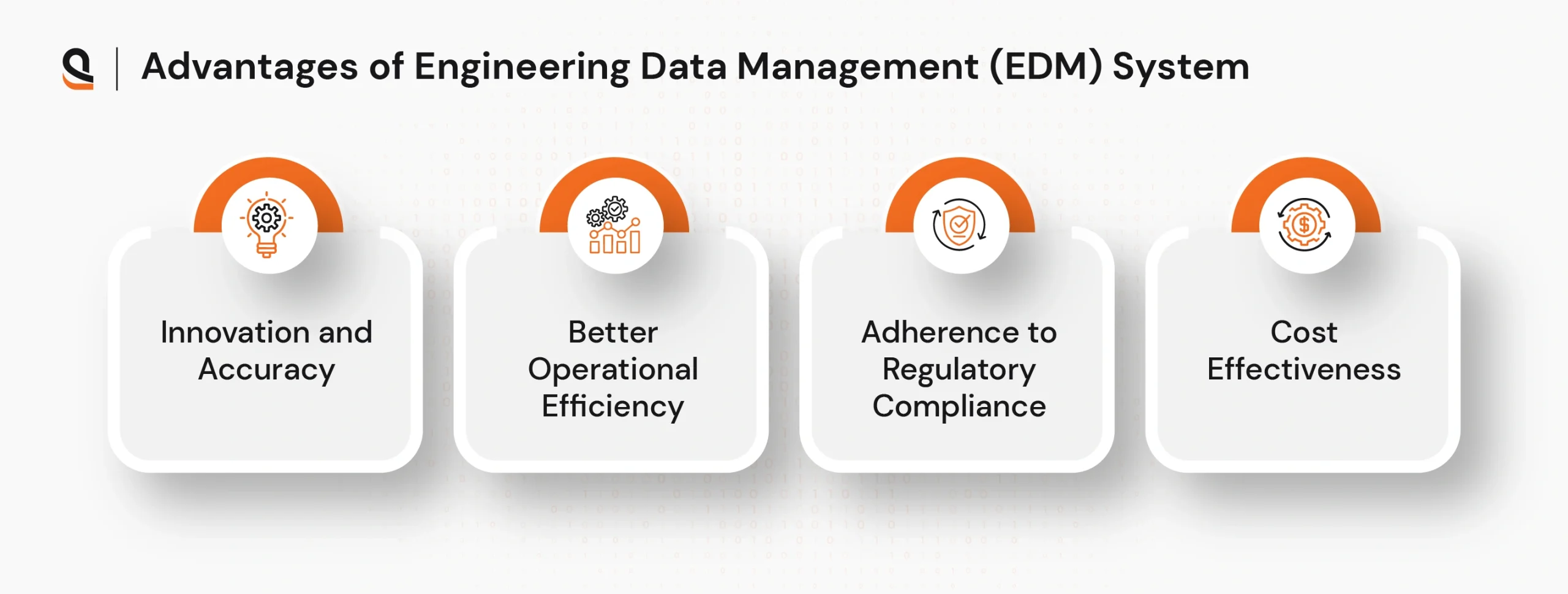

Key Benefits of an Engineering Data Management System

1. Innovation and Accuracy

Engineering data management systems save engineers’ time by allowing them easy access to the data and not wasting time relocating or recreating lost data. With easy data access and advanced analyzing capabilities engineering firms can drive innovation leveraging the historical data and tools to simulate future designs It also helps eliminating silos and fostering better collaboration between teams to share insights and drive innovation.

2. Better Operational Efficiency

Disorganized data can result in delayed projects, increased costs, and poor productivity for engineering industries. Implementing engineering data management software helps centralize all engineering data in a single and structured system, making data stored in a structured manner. With automated workflows, data gets updated in real-time, making data more accurate, error-free, and relevant.

3. Adherence to Regulatory Compliance

Engineering companies are subject to stringent regulations and require detailed documentation and records to pass the audits. Engineering data management systems help engineering firms stay compliant with automated storage and retrieval of documents required for regulation and compliance-related audits. A data management services provider helps reduce the risk of missing adherence to regulatory standards by integrating compliance into everyday workflows.

4. Cost Effectiveness

Inefficient and compromised data management results in costly errors, such as losing or misplacing critical project documents. This can result in materials wastage or missed deadlines for production, and loss of a client owing to dissatisfying service. Engineering data management software organizes data in a proper, structured manner and stores it securely, providing accurate information for better decision making. It also helps organizations analyze historical data to identify new opportunities and bottlenecks.

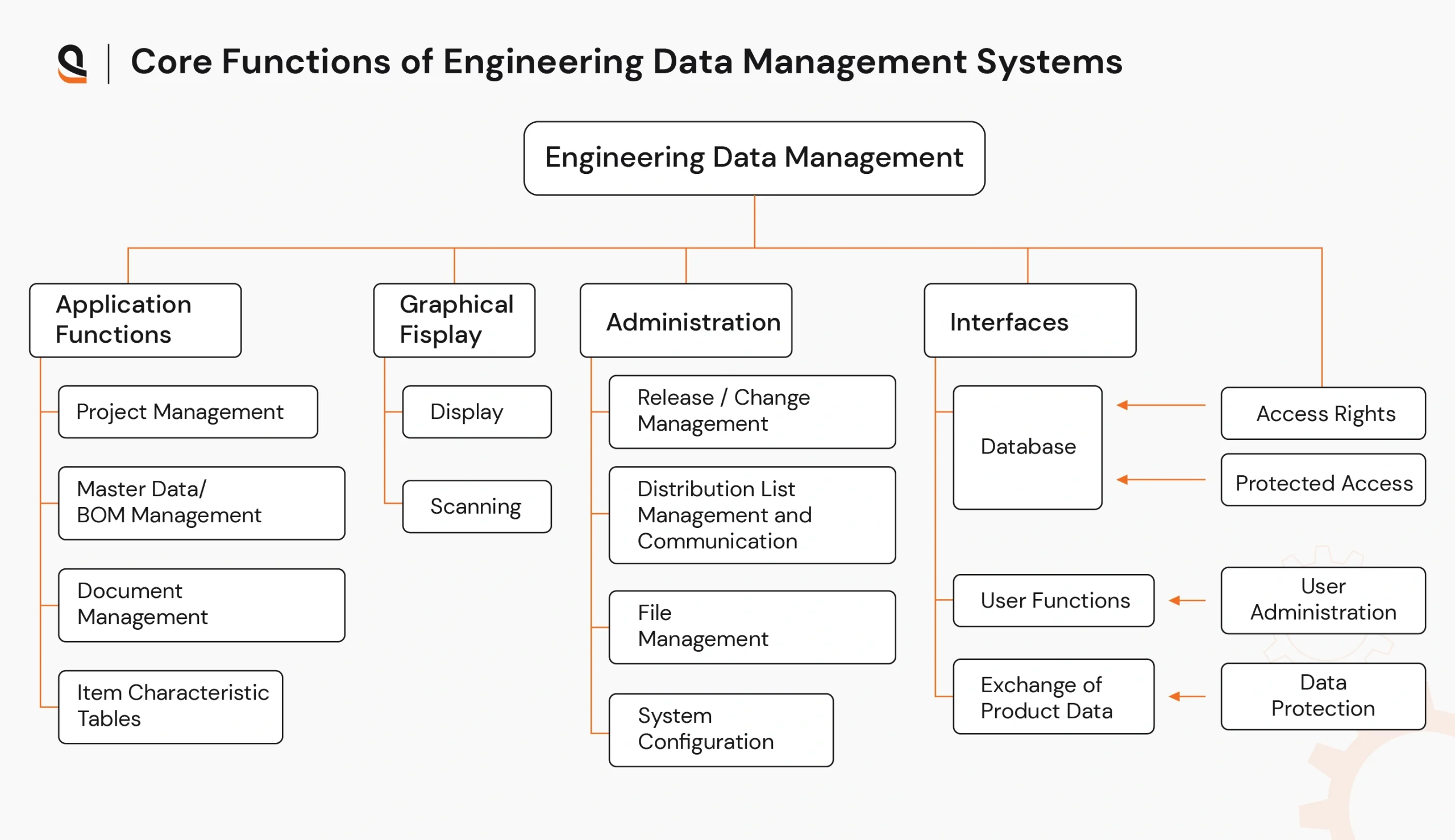

Essential Functions of an Engineering Data Management System:

- Data Storage: To store data such as files, documents, etc, ensuring security and easy accessibility.

- Data Retrieval: Facilitating quick and efficient search to locate the files utilizing advanced search tools, making business operations faster.

- Collaboration: Enhancing overall communication, data sharing, and updates across departments and teams for transparency and

- Data Processing: Collecting and processing data into a form that can be utilized and implemented in the projects.

As a leading data analytics consulting services provider, we leverage these functionalities to help engineering firms streamline workflows, enhance productivity, and improve overall operational efficiency.

How Engineering Data Management Supports Financial Sustainability?

Engineering companies can leverage engineering data management software to make well-informed decisions and get valuable insights from the data to drive efficiency, sustainability, and productivity. This data can help engineering companies have better resource utilization, materials management, and enhanced tracking that can impact overall sustainability.

How does EDM impact revenue?

- EDM ensures data accuracy, which helps reduce rework and maintain product quality.

- Helps with better resource planning and utilization, eventually reducing operational expenses.

- A proactive approach towards maintenance and minimized repair costs helps extend the life of machines and equipment.

- Engineering firms can enhance operational efficiency with centralized data access for better decision-making.

The Evolution of Engineering Data Management (EDM) in Green Engineering

Engineering data management has undergone a significant transformation over the recent years, especially with the rise of sustainability as a central engineering concern. What began as a method to manage CAD files and version control has now matured into a comprehensive digital framework that supports eco-conscious decision-making across entire lifecycles.

Today, modern engineering data management software enables real-time data sharing, predictive analytics, and lifecycle assessments—essential tools for green engineering. The integration of AI and cloud computing into EDM systems has further pushed the envelope, enabling proactive design improvements, smarter resource use, and the ability to simulate environmental outcomes before construction even begins.

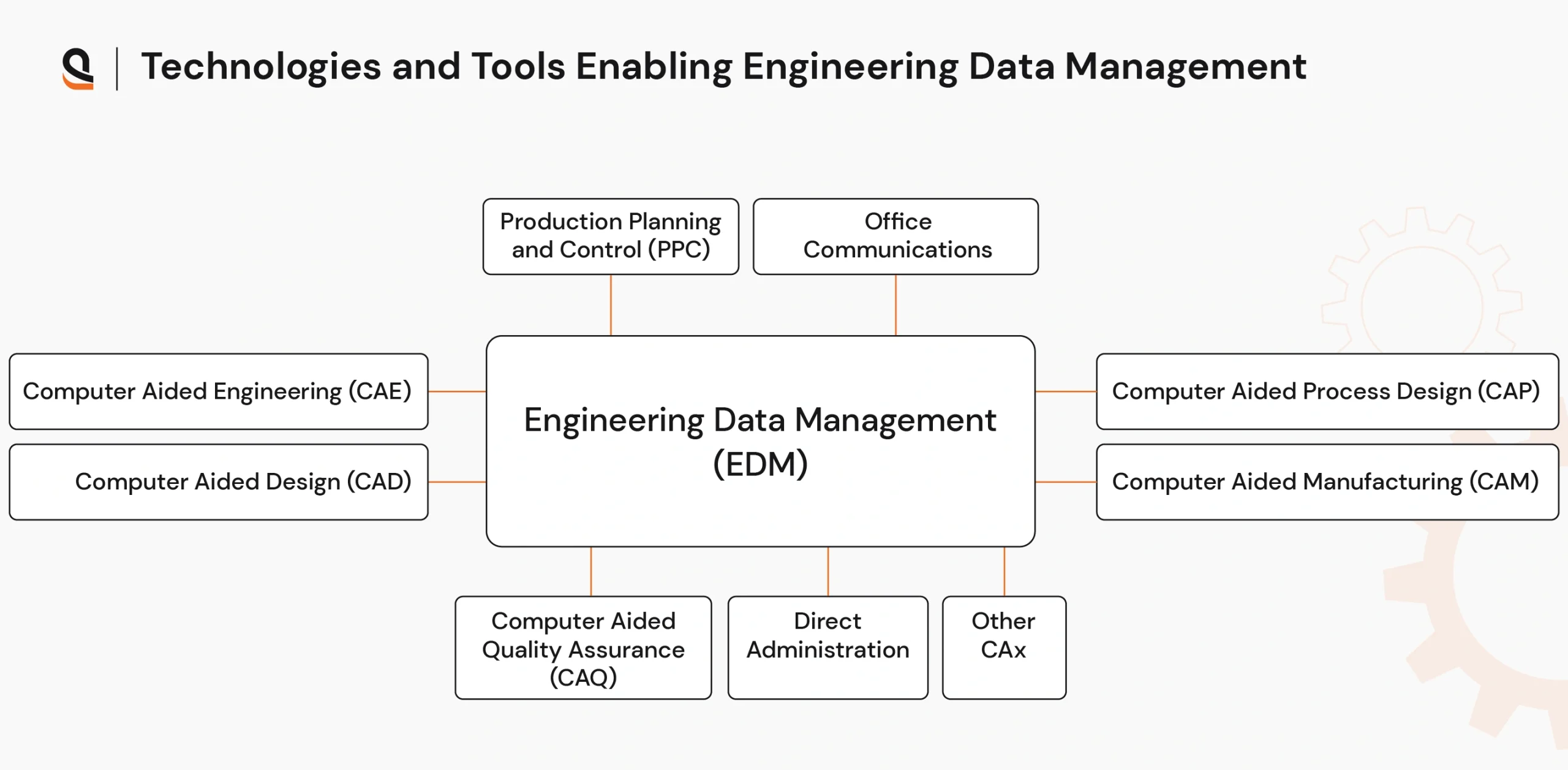

Key Tools and Technologies Supporting Engineering Data Management Systems

The engineering unit comprises multiple departments and teams where data is fragmented and spread across disparate systems. To manage, evaluate, and analyze huge and multiform data, several technologies listed below play a key role in implementing engineering data management systems effectively:

1. Product Lifecycle Management (PLM) Software

Product Lifecycle Management (PLM) systems are used to support and manage product development as well as management processes. PLM helps engineering firms manage data related to products in a centralized way. It also serves organizations to have better coordination, version control, workflows, and compliance tracking with seamless integration with engineering data management systems.

Features of PLM systems:

- Document Management: Allows organizations to store, retrieve, and share documents, ensuring seamless and real-time data exchange.

- Version Control: A system that facilitates the organization in managing multiple versions of the same unit of information.

- Bill of Materials (BOM) Management: Helps list all the production assemblies, sub-assemblies, parts, and raw materials to deliver a finished product.

- Communication Tools: The PLM system comprises advanced collaboration tools for teams and departments to have uninterrupted communication, coordination, and collaboration.

- Seamless Integration: PLM platforms get easily integrated with the current IT infrastructure and systems without disrupting the ongoing workflow.

2. CAD Data Management Tools

Computer-Aided Design (CAD) software is an integral component of engineering workflows. CAD software assists in creating, editing, organizing, and sharing data. CAD software can be easily integrated with other enterprise tools and systems. It ensures smooth data exchange and collaboration among designers, ensuring better productivity and design quality.

Features of CAD software:

- 3D Modeling: Allows designers to create detailed three-dimensional models of parts and assemblies, enabling visualization, testing, and design optimization.

- Parametric Design: Enables users to create models based on defined parameters and constraints, allowing easy adjustments and modifications to dimensions or features.

- Automated Drafting: Automatically generates 2D technical drawings from 3D models, streamlining the creation of precise and standardized blueprints.

- Collaboration Tools: Facilitates real-time collaboration among multiple designers and engineers, enabling them to work together on the same model.

- Data Management: Ensures that all design data, including drawings, models, and specifications, is organized, stored, and easily accessible.

3. Data Management Systems (DMS)

Data Management Systems (DMS) support engineering firms in storing, organizing, and retrieving engineering data efficiently. DMS is a centralized repository for the engineering data that includes technical documents and process information related to a product’s design, manufacturing, assembly, inspection, testing, and maintenance. It enhances data integrity, decision making, and collaboration by ensuring data accessibility, reliability, and processing.

Data Management System’s Key Features:

- Data Security: DMS protects data from unauthorized access and potential data breaches, keeping it stored securely with security measures such as access controls and encryption.

- Access Control: Keeps your data protected by controlling who can access the data and maintaining data integrity.

- Backup: Data backup features are often provided with DMS to prevent data loss.

- Data Acquisition and Validation: Ensuring data accuracy and relevance is collected from multiple sources.

- Data Processing: Data is processed into a usable form and effectively used in projects.

-

- Explore this related guide: Boost Engineering Revenue & Productivity by 40% with AI

Conclusion

Sustainability in large-scale engineering is a core requirement for profitability, compliance, and public trust. With engineering data management as a strategic pillar, organizations can balance environmental stewardship with commercial success.

Whether you’re overseeing a multi-billion-dollar infrastructure build or managing complex industrial assets, the right engineering data management software turns data into a driver of long-term value.

Sustainable engineering begins with sustainable data. And with the right system in place, sustainability pays. If you are seeking an experienced digital transformation partner and an engineering data management company, contact us to access comprehensive data management services and solutions.