For manufacturers, every dollar saved in waste reduction directly translates to higher margins and a more sustainable bottom line. This particular data management waste takes several forms, each of which can hinder efficiency and increase operational costs. Data silos occur when information is isolated in different systems, making it difficult for teams to access and share crucial data.

Manual data entry errors introduce inaccuracies and delays, while data redundancy leads to unnecessary duplication and wasted storage resources. Moreover, late access to data prevents timely decisions, while variable data standards create discrepancies while reporting, making it simply impossible to generate actionable insights. These inefficiencies highlight the growing importance of data analytics in manufacturing, which enables teams to extract meaningful insights, optimize operations, and drive better decision-making.

Along with this, leveraging cloud computing in manufacturing allows for seamless data integration, accessibility, and scalability across the enterprise. Furthermore, predictive analytics in manufacturing empowers businesses to anticipate issues before they arise—whether it’s equipment failure, supply chain disruptions, or demand fluctuations—enabling more proactive and cost-effective responses. By utilizing real-time data and machine learning models, your business can not only reduce waste but also transform the way you approach production optimization. The time to act is now!

Let’s explore how you can start reducing manufacturing data waste and improve operational efficiency, with integrating cloud computing.

The Hidden Challenges to Cope with Manufacturing Data Management Waste

Poor data management is a silent killer of efficiency and profitability. It gives rise to manufacturing data management that manufacturers have to deal with. Here is how bad data management cuts into the pockets of manufacturers:

1. Data Overload and Fragmentation

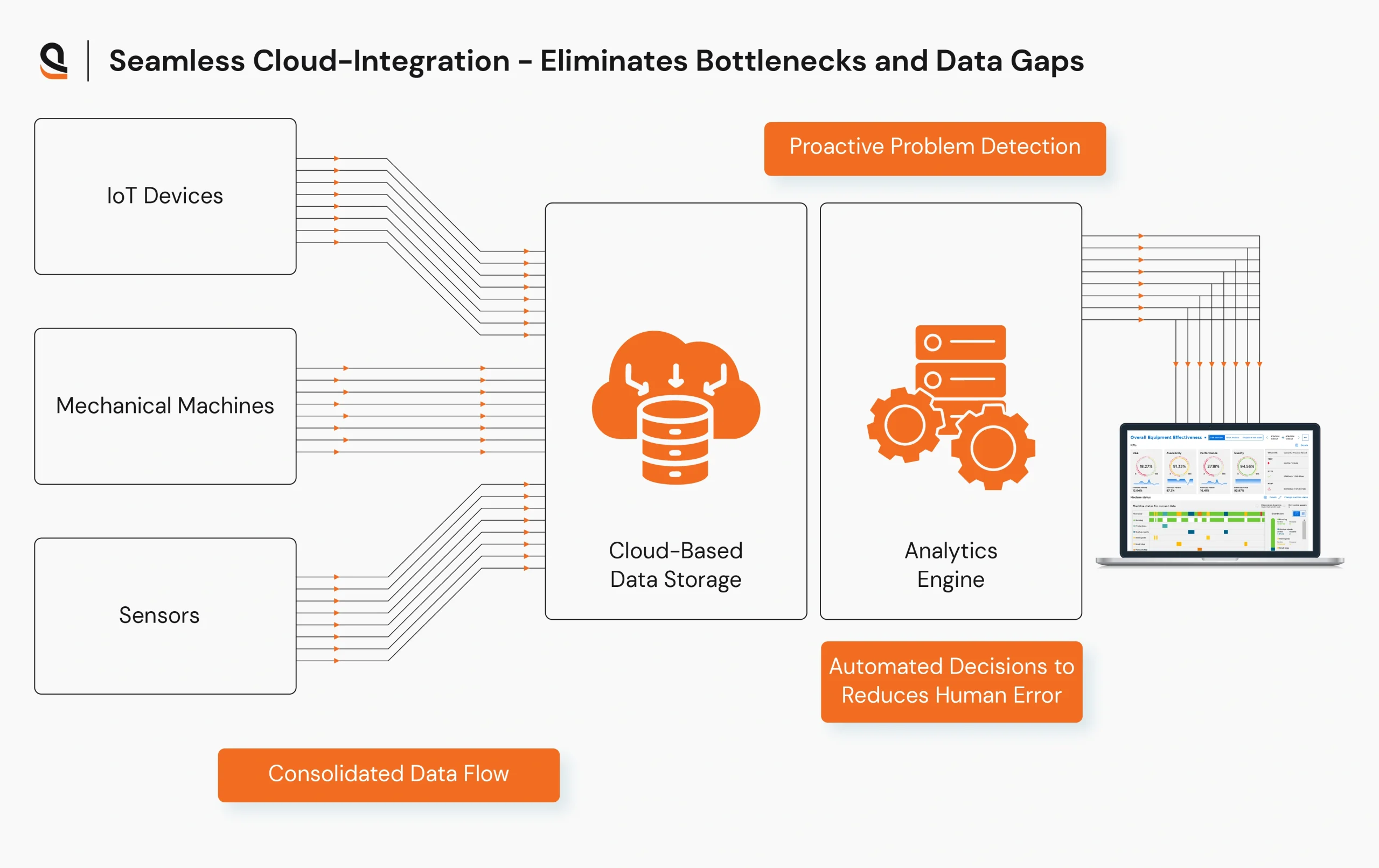

Manufacturing systems generate vast amounts of data from various sources—machines, sensors, and production lines. Without a solid manufacturing data management system to consolidate this data, it ends up scattered across silos, creating confusion and inefficiencies. This is where cloud computing in manufacturing plays a key role in centralizing data, providing a unified platform for seamless access and better decision-making.

2. Lack of Real-Time Insights

In a fast-paced manufacturing environment, waiting for data to be processed or analyzed can delay action on potential issues, leading to unnecessary downtime and wasted resources. By leveraging data analytics in manufacturing, manufacturers can gain real-time insights, enabling quicker, more informed decisions to keep operations running smoothly and prevent costly delays.

3. Manual, Error-Prone Decision Making

Many manufacturers still rely on manual processes for decision-making, which can be slow, inconsistent, and prone to human error. This leads to delays, mismanagement of resources, and inefficient use of time. Predictive analytics in manufacturing can automate these decisions, making them faster and more accurate, while also minimizing human error and optimizing resources.

4. Overproduction and Stockouts

Manufacturers often struggle with aligning production with actual demand, leading to overproduction and excess inventory, or stockouts that cause delays. Both scenarios lead to wasted resources or missed opportunities. Data analytics in manufacturing can offer a more accurate understanding of demand patterns, helping to balance production and reduce waste. Predictive analytics in manufacturing further enhances this by forecasting demand trends, enabling proactive planning.

5. Slow Data Flow and Latency

When data is delayed or not processed quickly enough, it can lead to inefficiencies in decision-making, with manufacturers missing out on timely opportunities to optimize production. Implementing cloud computing in manufacturing allows for faster data processing and seamless integration across systems, reducing latency and enabling quicker decision-making to optimize production processes.

6. Inability to Continuously Optimize Processes

Without continuous monitoring and the right insights, manufacturers may miss bottlenecks and inefficiencies in their processes, which can lead to ongoing resource waste and stagnation. Manufacturing data management systems, combined with predictive analytics in manufacturing, provide continuous process monitoring and offer actionable insights, enabling manufacturers to identify areas for improvement and optimize processes in real time.

How AQe Digital Uses Cloud Computing in Manufacturing to Narrow Down Data Management Waste

At AQe Digital, we know the most critical issue that the manufacturing data analytics sector faces is waste in data management. The continuous flow of data sent from machines, sensors, and production lines easily overwhelms anyone unprepared with adequate tools and processes for analysis and management.

It is here, therefore, that our practice comes into play—cloud computing in manufacturing. It transforms the factorial ways of manufacturers using and managing data to eliminate inefficiency from decisions that will optimize their operations. This is how we specifically attack waste in manufacturing data management:

1. Consolidated Processing of Data Ensures Uniformity and Accuracy

Removing data silos essentially ensures that manufacturers are only working with consistent and reliable data, which ultimately helps reduce errors, duplicate work, and the data silos that lead to inefficiencies in decision-making and operations.

- We merge data from disparate sources into one, highly centralized place. By means of cloud data-storage solutions, we develop powerful conduits through which machines, IoT sensors, and production lines can process and store data all at once-any loss of duplicate information.

We merge data from disparate sources into one, highly centralized place. By means of cloud data-storage solutions, we develop powerful conduits through which machines, IoT sensors, and production lines can process and store data all at once-any loss of duplicate information.

2. Real-Time Monitoring with Instantaneous Data Analytics in Manufacturing

The real-time information pinpoints the inefficiency and upcoming problems (equipment malfunction, bottlenecks in process) before it yields any delays or waste. This kind of proactive approach in predictive analytics in manufacturing would ensure the reduction of downtime and enhancement of productivity.

- Using IoT sensors, machine learning models, and cloud infrastructure to provide real-time data analytics in manufacturing, thus continuously feeding them immediate insights into their processes.

3. Automated Resolution of Data-Driven Decisions

By taking away manual intervention from the stage, automation eliminates the introduction of potential human error in the process and, thus, an accelerated response to changing conditions, efficient resource utilization, less time spent being idle, reduced excess stock, and the optimization of throughput.

- Data analytics in manufacturing is introduced into workflows to support rapid data-informed decision-making. This activity includes automatically adjusting production schedules, machine operations, and inventory management based on real-time insights.

4. Predictive Analytics in Manufacturing to Prevent Overproduction and Stockouts

It is the process of predictive analytics in manufacturing that aligns with production with actual demand. This, minimizes instances of overproduction that lead to excess stock and stockouts, which can cause operational delays. With precision in forecasting comes waste reduction; only the right amount of materials and products are produced.

- Demand forecasting, monitoring of machine health, and predictive analytics in manufacturing concerning potential production hiccups; having an understanding of prior data and trends allows us to accurately predict future needs.

5. Optimize Data Flow and Reduce Latency

So manufacturers get the insights they need in real-time, this minimizes the inefficiencies that arise from delayed data and decision-making and enhances the speed of operations while reducing wasted resources.

- We optimize the data flow from machines, sensors, and other devices. Seamless integration with cloud platforms like Google Cloud, Microsoft Azure, and AWS ensures that such data gets captured and processed without unnecessary delays for analysis.

6. Continuous Improvement and Data-Driven Process Optimization

Continuous data-driven optimization helps remove inefficiencies, streamline workflows, and minimize resource wastage. Proactively dealing with problems as they arise, along with continuous optimization, keeps the manufacturers lean and free from wastage due to the burden of obsolete processes.

- We use data analytics in manufacturing to continually monitor bottlenecks and areas for improvement related to manufacturing processes. We provide actionable insights about processes to manufacturers via comprehensive reports and dashboards.

Advantages of Cloud Computing in Manufacturing for Process Optimization

With years of experience in helping manufacturers streamline operations and extract maximum operational efficiency, we enhance work throughput while reducing waste and cutting downtime. By leveraging cloud computing in manufacturing, we ensure seamless data integration and real-time access to insights. Here is how our specifically tailored solutions have yielded very large results for our clients:

- Our predictive analytics in manufacturing setup analyzes real-time machine data to actually predict failure before it occurs. This has helped our clients maintain machines longer, create less expensive stops in production, and by extension, average an overall equipment efficiency(OEE) increase across their plants.

- Our intelligent real-time dashboards have transformed the processes by which manufacturers track and manage production flows. By automating data analysis and decision-making, we have helped our clients make better decisions much faster, enabling them to respond quickly to operational crises.

- We have also helped clients reduce their systems’ time to implementation through the simulation of their production systems, thus accelerating the time-to-market for new products/process changes.

How AQe Digital Assists Manufacturers in Waste Reduction

At AQe Digital, we focus on driving measurable improvements in manufacturing operations by using advanced technologies to reduce waste. Our approach helps manufacturers minimize inefficiencies, optimize processes, and improve productivity. Here’s how we do it:

1. Custom Data Analytics Platforms – Tailored to Your Needs

- Each manufacturing process is different. Hence, we build custom data analytics platforms aimed at bringing efficiency to your processes. We integrated data analytics in manufacturing AI-ML and cloud computing to ensure that data from your production lines and equipment undergoes real-time processing and analysis.

- This customized strategy enables pinpointing of inefficiencies such as wasteful energy consumption, bottlenecks in production, and undesired downtime. By gaining specific actionable insights, we can guide you to avoid unnecessary production, bring about optimal resource allocation, and keep you from costly mistakes leading to waste.

2. AI-Driven Process Optimization – Smart Manufacturing & Continuous Monitoring

- Among the consultancy, we also partner with the AI-based solutions of constant monitoring production data against irregular patterns that tell about inefficiencies. By this means of real-time analysis, adjustments in processes that can help increase overall efficiency can be prescribed.

- By the predictive models, failures in machines and even maintenance can be anticipated, letting time down. And with the help of optimizing the workflows in production by saving time, man, or materials, we can stretch an output too.

3. Seamless Cloud Integration with Existing Systems – Smooth Data Flow

- Bringing our solutions into your existing systems (ERP, MES, and other production tools) guarantees seamless flow of data across the platform without manual input.

- Thus, that integration minimizes data entry errors, slows down information sharing, and mismatches data sets. With real-time data flowing into your decision-making process, you must make faster and better informed decisions based on today’s facts – which are good decisions that stop waste arising from misinformation or stale data.

4. Scalable Cloud-Based Solutions – Adaptable to Your Growth

- Our cloud solutions are designed to grow with your business. As your production increases demand, so does the ability of our software to accept greater amounts of data-all without compromising performance and security.

- Scalability with cloud systems allows you to increase operations efficiently, avoiding investments in costly on-site infrastructure. Beyond that, changing operating systems in the cloud is easier to maintain and update and helps to lower the origin and costs of overhead and waste tied to legacy systems.

Wrapping Up: The Benefits of Cloud Computing for Smart Manufacturing Data Management

The control of waste and efficiency improvement can be provided by embedding AI and ML integration in the cloud into a manufacturing process. Here is a quick summary of some key advantageous points:

- Data Streaming: IoT devices and production lines will give you an immediate streaming of data for rapid detection of inefficiencies.

- Predictive Maintenance: Machines predict turning failures to avoid unplanned shutdowns, hence prolonging machine life and curtailing repair costs.

- Optimized Resource Application: Advanced machine learning models can improve consumption levels of overproduction as well as excess stock through inventory/production scheduling efforts.

- Seamless System Integration: All your systems will have a seamlessly integrated flow of data and be free from manual keying of data errors.

- Flexibility and Scalability: Cloud solutions scale up with your growth, thus providing a secure scalable infrastructure with no need for expensive hardware on-site.

Manufacturers can now waste less and take better decisions in the long run. With our manufacturing IT solutions, you can achieve continuous operational efficiency.