Cutting-edge smart devices are fundamentally reshaping the future of factory logistics by spearheading the transformation towards Industry 4.0 and the sophisticated concept of the smart factory.

They are changing how smart factory logistics work. From tracking inventory in real time to predicting delays before they happen, these devices are making operations smarter, faster, and more efficient.

With IoT technology in smart devices, factories are no longer guessing. They’re making decisions based on data.

For manufacturers, operational and financial benefits remain the top priorities fueling this investment. According to a Deloitte Analysis, 92% of manufacturers view smart manufacturing as the key driver of competitiveness, while 85% believe it will transform production and boost talent attraction.

It’s all about staying ahead. IoT in manufacturing and IoT connectivity for smart factories are solving problems that cost time and money. Let us break down how cutting-edge smart devices are solving real supply chain & logistics challenges.

What Are Smart Factories and Their Role in Modern Manufacturing

A smart factory is a modern manufacturing setup where machines, systems, and people are connected through advanced sensors, data networks, and automation tools.

It uses cutting-edge smart devices and IoT technology to monitor processes, manage inventory, and make decisions in real time. This enables factories to operate more efficiently, reduce downtime, and respond promptly to changing demands, all while enhancing accuracy, safety, and overall productivity.

With IoT in manufacturing, inventory systems become dynamic rather than static. Stock levels, storage conditions, and movement data are tracked continuously, providing logistics teams with actionable insights at all times.

The key role of smart factories, as seen in modern manufacturing, includes:

Real-Time Inventory Monitoring

- Sensors track stock levels instantly.

- Automated alerts are triggered when thresholds are crossed.

- Ensures stockouts or overstocking are addressed proactively.

Predictive Demand Forecasting

- Data from past usage patterns helps predict future needs.

- Seasonal trends and production schedules are incorporated for better planning.

- Reduces emergency orders and improves stock rotation.

Enhanced Accuracy and Traceability

- Every unit’s location and condition are logged automatically.

- Serial number tracking improves accountability and compliance.

- Streamlines audits and reporting with up-to-date information.

Optimized Reordering and Procurement

- Integration with supply chain systems enables automatic reorder triggers.

- Procurement decisions are aligned with actual consumption data.

- Reduces lead times and minimizes excess inventory.

Condition Monitoring for Sensitive Materials

- Environmental sensors track temperature, humidity, and vibration.

- Alerts are sent in case of deviations, preventing spoilage or damage.

- Useful for pharmaceuticals, chemicals, and perishables.

Improved Safety and Compliance

- Automated alerts for hazardous conditions ensure immediate action.

- Tracks equipment health and maintenance schedules.

- Supports audits, regulatory compliance, and risk management.

How Industrial IoT Is Revolutionizing Inventory Management – A Real-World Success Story

Siemens’ electronics manufacturing plants are a great example of how industrial IoT solutions are transforming logistics. By connecting machines, storage systems, and workflows through IoT in manufacturing, they’ve created a more intelligent and responsive inventory system.

What changed?

Instead of relying on manual audits and paper logs, their logistics teams now track parts and materials in real time. Sensors monitor stock levels, temperature, and movement, while automated alerts flag issues instantly, whether it’s a missing batch or a handling error.

Impact of Introducing IoT Solutions

- 20% increase in operational efficiency

- Fewer stock discrepancies

- Improved safety and compliance

- Faster response to production delays

Nearly half of Siemens’ manufacturers (49%) see operational improvements that boost efficiency and reduce waste. For them, it is not just about technology; it is about giving teams the tools to stay ahead.

Siemens’ experience shows how IoT connectivity for smart factories isn’t future talk—it’s happening now, and it’s driving real results.

What Are Smart Devices Driving Logistics Innovation?

Smart devices in factory logistics are connected, data-driven tools and systems equipped with advanced sensors, computing power, and communication capabilities.

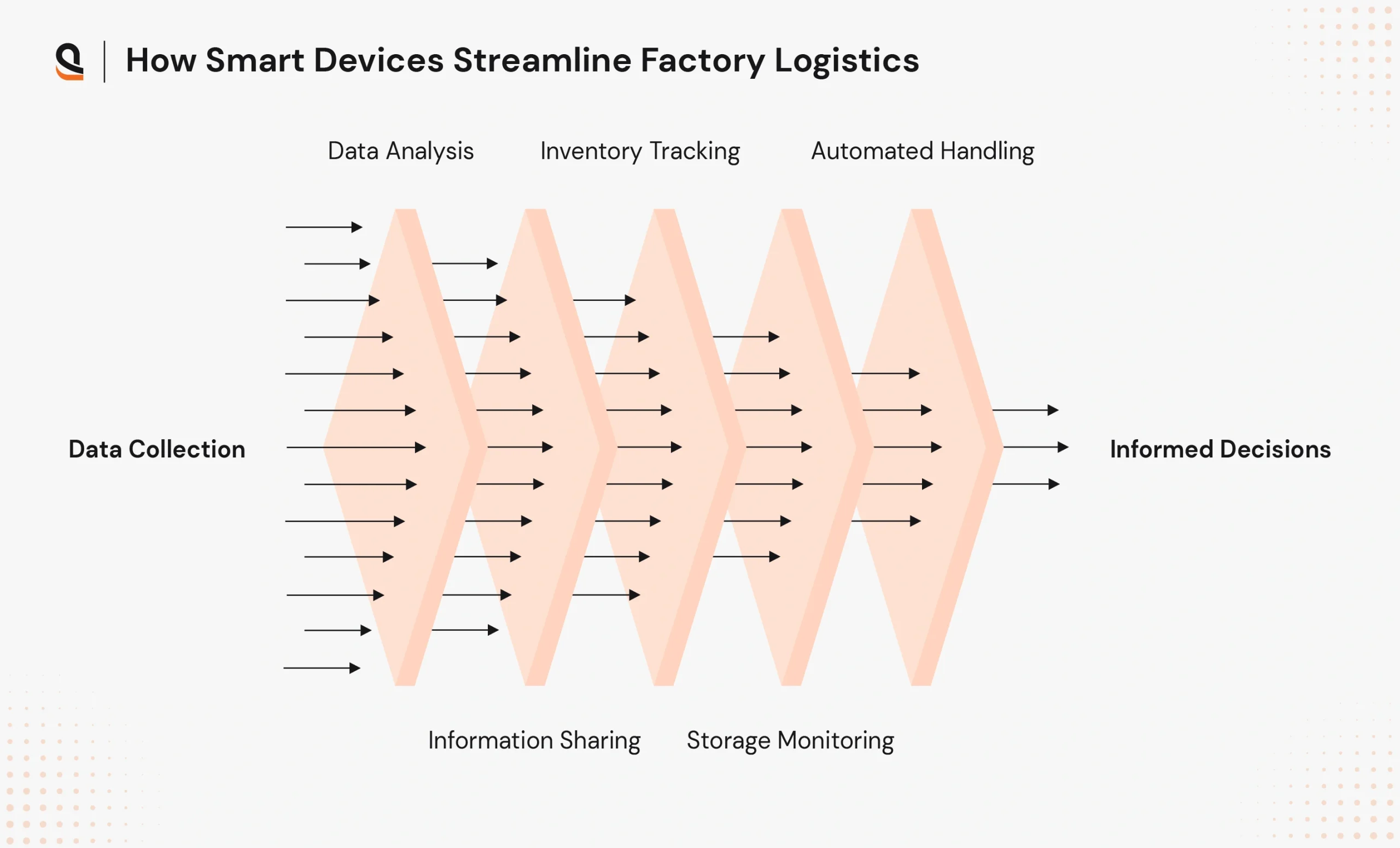

These cutting-edge smart devices collect, analyze, and share information in real time, helping logistics teams track inventory, monitor storage conditions, automate material handling, and make faster, more informed decisions.

By integrating IoT technology in smart devices, they enhance accuracy, reduce downtime, improve safety, and optimize workflows—making logistics operations more efficient, reliable, and responsive to changing demands.

A quick overview of the essential smart devices transforming logistics today:

Cutting-edge smart devices allow logistics teams to monitor stock, prevent delays, and respond quickly to changing needs.

Advanced Sensors

These small but powerful devices track everything—from where stock is stored to the temperature it’s kept at. They help prevent stock shortages and spoilage by sending alerts when something is off.

Automated Guided Vehicles (AGVs) and Robots

These machines move materials around the factory without needing human help. They follow smart routes and adjust to changes, making logistics faster and safer.

IoT Gateways and Edge Devices

These act like local controllers, gathering data from sensors and sending it to cloud systems. They ensure smooth communication and quick decisions, even when the network is unstable.

Wearable Devices

Smart glasses or wristbands help warehouse staff by providing hands-free access to inventory information or guiding them through tasks. They improve efficiency and reduce mistakes.

Smart Storage Systems

These shelves and bins adjust automatically based on the size or type of goods. Combined with intelligent algorithms, they make storing and retrieving inventory easier and more space-efficient.

Cloud-Connected Monitoring Platforms

All the data from sensors, vehicles, and staff devices is collected in one place. Managers can see stock levels in real time, track issues before they happen, and plan better using predictive tools.

Whether you’re handling inventory, planning supply chains, or managing operations, these technologies are helping factories stay efficient and competitive.

Building Smarter Logistics Through Interoperability

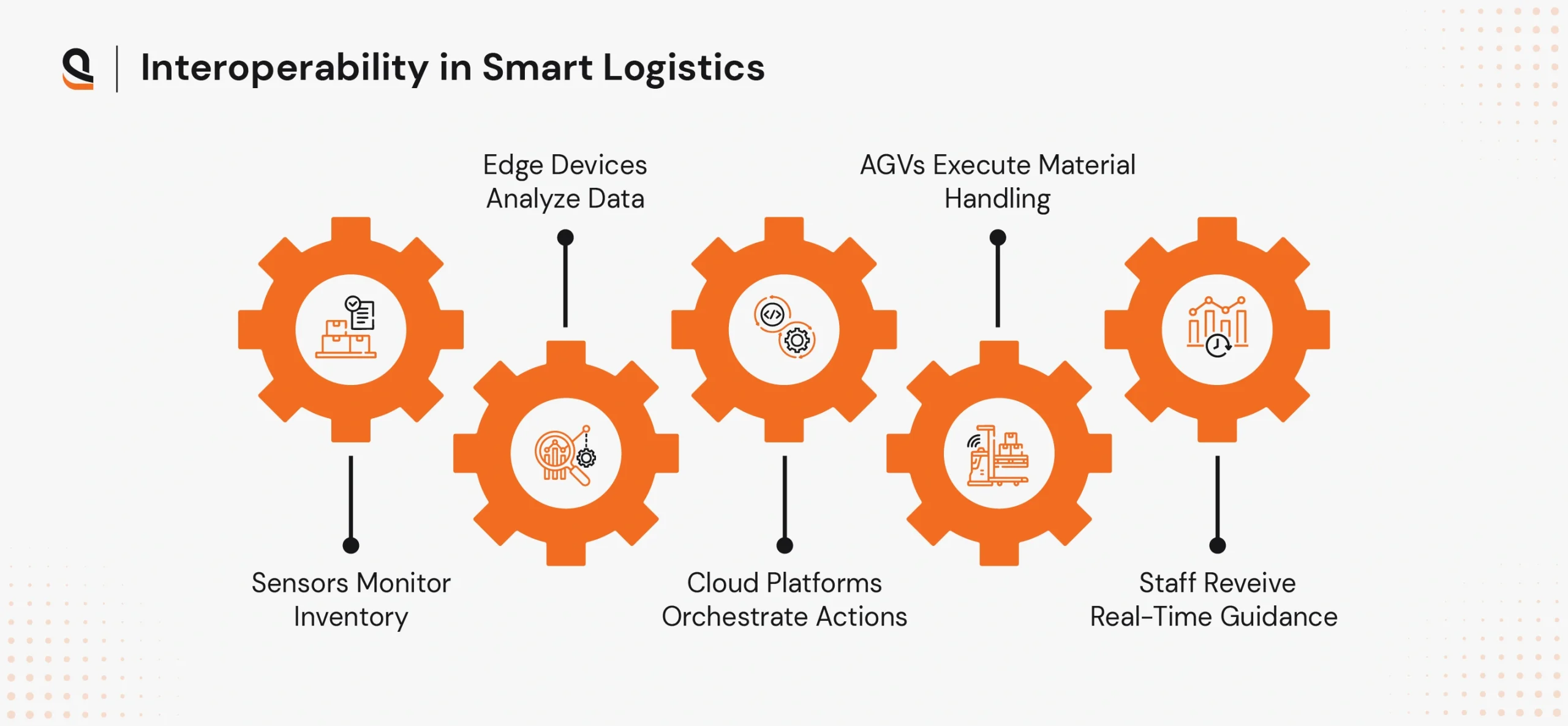

The true strength of smart logistics lies in how devices communicate and collaborate in real time. It’s not enough to deploy sensors or robots; what matters is how they exchange data and support decision-making. This capability, known as interoperability, ensures that machines, systems, and platforms work together seamlessly.

Sensors monitor inventory continuously.

Advanced sensors track stock levels, location, and environmental conditions in real time. For instance, when inventory falls below a set threshold, the system registers it immediately. This eliminates the delays associated with manual checks or periodic audits.

Edge devices analyze and forward critical data.

These devices act as local processing hubs. They filter incoming sensor data, validate it, and transmit relevant alerts to the cloud or enterprise systems. By handling data at the source, edge computing reduces latency and ensures critical decisions are made without delay.

Cloud platforms orchestrate automated actions.

Once data is processed, cloud systems integrate with other logistics tools to trigger actions such as automated reorder requests, stock adjustments, or reporting updates. This eliminates human intervention, reducing errors and improving responsiveness across supply chains.

AGVs and autonomous robots execute material handling.

Automated guided vehicles and robots transport materials within the facility using pre-defined routes optimized by AI and real-time tracking. This improves throughput, reduces manual labor, and ensures goods are moved safely and efficiently.

Warehouse staff receive real-time guidance.

Wearable devices, such as smart glasses or voice-enabled headsets, provide step-by-step instructions for tasks like picking, packing, and sorting. With instant access to inventory data and workflows, staff operate more efficiently and with fewer errors.

It is this seamless flow of information that helps factories improve inventory accuracy, reduce downtime, and scale operations with confidence.

How AQe Digital Ensures Smart, Reliable, and Scalable Logistics

At AQe Digital, we don’t just provide IoT devices we build connected, secure, and actionable logistics solutions that meet the technical needs of modern factories. Here’s how we take care of the key considerations:

Data Security & Compliance: Data is the backbone of logistics operations. Inventory reports, equipment performance, and transportation schedules are sensitive assets that must be shielded from threats.

We make sure to,

- Implement end-to-end encryption across devices, networks, and cloud platforms.

- Use secure communication protocols to prevent unauthorized access.

- Ensure systems meet regulatory standards, keeping operational and sensitive data safe.

Reliable and Resilient Networks: Logistics depends on real-time data flow. Downtime can disrupt schedules, increase costs, and delay deliveries. That’s why network reliability is a non-negotiable requirement.

Some best practices include,

- Deploy low-latency connectivity solutions, including 5G, Wi-Fi 6, and industrial Ethernet.

- Build redundancy and failover mechanisms to prevent downtime.

- Ensure uninterrupted data flow for real-time inventory tracking and process automation.

Seamless System Integration (Interoperability): Factories rely on a mix of legacy equipment and new technologies. A flexible solution ensures devices from different vendors communicate effortlessly.

The best approach to this has,

- Open standards like MQTT and OPC-UA for cross-device compatibility.

- Modular integration frameworks that reduce implementation time.

- Future-proof designs that adapt as operations expand.

Data-Driven Insights and Visualization: Data visualization is at the core of transforming logistics into a data-driven process. When devices, networks, and software solutions work together securely and efficiently, logistics teams gain the tools they need to reduce errors, optimize workflows, and improve safety.

For leadership, these capabilities mean:

- Greater operational visibility for faster decision-making.

- Data-backed insights that support strategic planning and cost control.

- Agility to respond to market changes without large-scale infrastructure changes.

We give high importance to data visualization by the following best practices that,

- Convert real-time data from devices and systems into easy-to-understand dashboards.

- Provide predictive analytics to optimize inventory management, reduce downtime, and improve supply chain decisions.

- Support decision-making with visualizations that highlight key performance indicators for operations and leadership teams.

Final Thoughts

The future of manufacturing is no longer just about machines. It is about how machines, systems, and people work together. With cutting-edge smart devices, IoT-enabled solutions, and data-driven insights, factories can achieve faster decision-making, greater efficiency, and more reliable operations.

By connecting devices, integrating systems, and visualizing data in real time, logistics teams gain clarity and control like never before. It’s not just about tracking inventory or automating processes. It’s about building a flexible and intelligent infrastructure that can adapt to changing demands, mitigate risks, and unlock new growth opportunities.

Investing in manufacturing IT services and smart factory logistics is a practical strategy to stay competitive today while preparing for tomorrow. With the right technologies and expertise, factories can move from reactive operations to predictive, insight-driven performance, turning complexity into clarity at every level.

FAQs

We provide IoT-enabled smart devices and system integration services that optimize material movement, inventory management, and workflow coordination—making your logistics faster, more accurate, and cost-efficient.

AQe Digital delivers end-to-end IoT product engineering, including device integration, cloud connectivity, and data visualization dashboards, helping factories operate smarter and make real-time, data-driven decisions.

Yes. Our industrial IoT services are designed for seamless system integration, connecting legacy machinery, sensors, and software platforms to create a unified smart factory ecosystem.

We turn complex IoT and operational data into interactive dashboards that show inventory levels, equipment status, and workflow metrics—helping decision makers spot bottlenecks, reduce downtime, and plan better.

Absolutely. With smart factory logistics solutions, you can automate workflows, reduce manual errors, improve inventory accuracy, and cut operational expenses, delivering measurable ROI for your factory.

Our modular and scalable approach ensures fast deployment, whether it’s adding smart devices, connecting systems, or setting up dashboards—so your factory starts seeing benefits quickly without disrupting existing operations.

Yes. Every factory is unique. We provide tailored IoT manufacturing services, including device selection, workflow optimization, and data visualization—so your smart factory solution fits your operations perfectly.

We combine IoT expertise, system integration capabilities, and actionable data insights to help factories optimize logistics, enhance efficiency, and scale operations confidently. Our services are focused on tangible business outcomes, not just technology deployment.