Machine failures or downtime are the most important causes of delayed operations and overdue deadlines for the manufacturing industry. Manufacturing downtime could fall under two categories – planned maintenance or unplanned maintenance due to equipment failure, machine failure, raw material stock-out, and other possible reasons. However, costlier delays and complications within workflows occur due to unplanned downtime, unlike planned downtime.

Earlier manufacturers used to depend on manual and traditional maintenance methods lacking accuracy and a proactive approach. It often leads to unplanned breakdowns and expensive disruptions to manufacturers over production lines. However, the implementation of technologies like cloud computing and AI for Manufacturing has transformed the sector. For instance, many industries face issues with supply chain disruptions impacting their predictive maintenance schedule. However, AI-enabled systems help businesses schedule dynamically whenever required parts get delayed due to supply chain issues. Integration of advanced technologies optimized productivity, operational efficiency, and cost-effectiveness by minimizing downtime and facilitating data-driven decisions.

AI-enabled devices and applications gather data from machines, workers, and sensors and process it for data-driven decision-making and to extract actionable insights. Predictive analysis can predict issues before they occur and enables remote monitoring of equipment using smart algorithms. According to a report by Markets and Markets, AI in the manufacturing sector is expected to grow at a rate of 45.6%, from $3.2 billion in 2023 to $20.8 billion by 2028.

Embracing AI has shifted manufacturers from a ‘fix-it-when-it-breaks’ approach to strategic, data-driven maintenance planning.

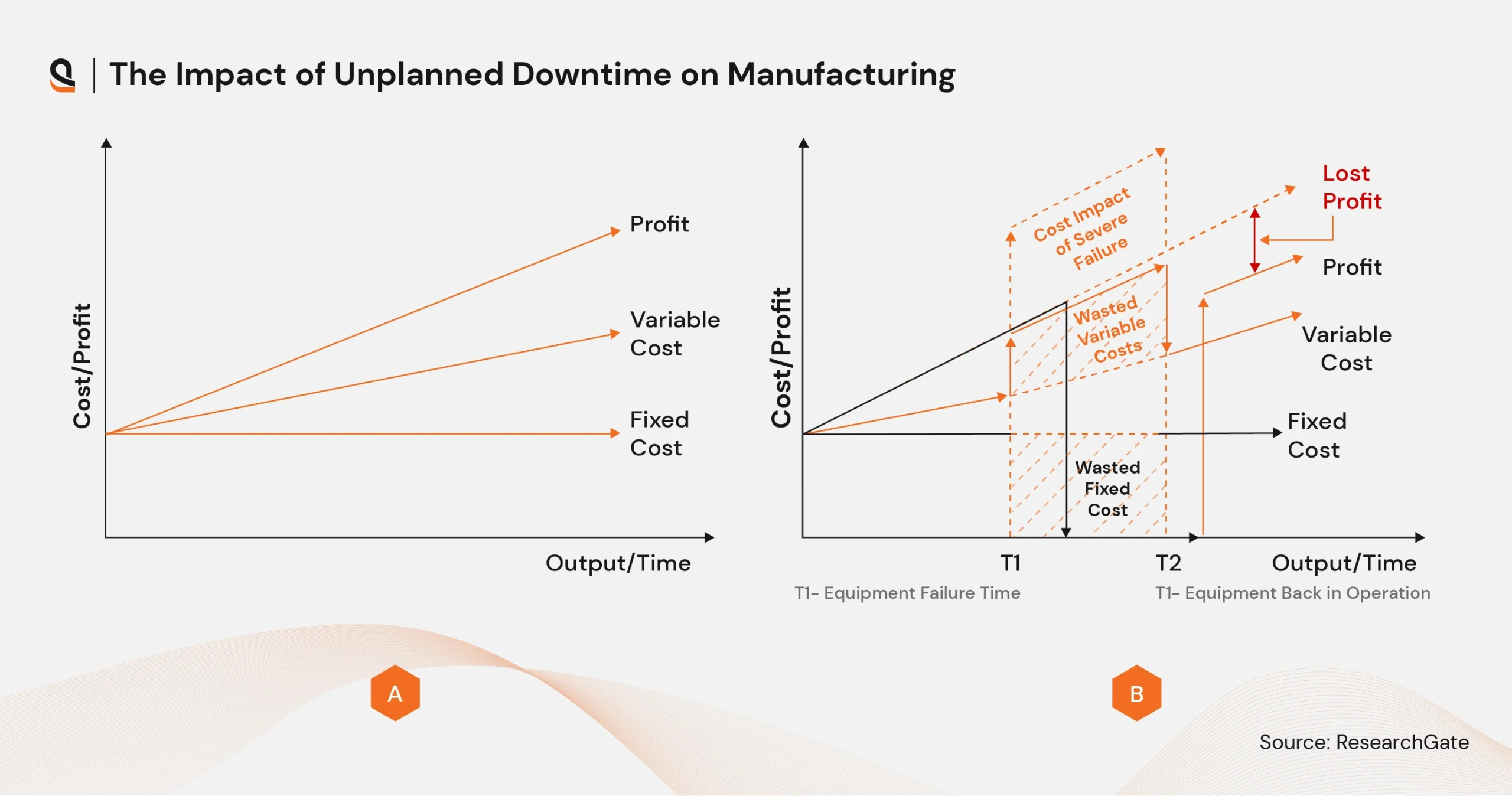

The Impact of Downtime on Manufacturing

Both planned and unplanned downtime disrupt the manufacturing process, impacting entire production workflows. Planned downtime can be scheduled with minimum disruption, but unplanned downtime caused by equipment failure, human errors, or supply chain disruptions adversely impacts multiple aspects of manufacturing.

Some key consequences of unplanned downtime include:

Financial Losses: Idle machines, resources, and delays in manufacturing result in poor ROI. Additionally, major breakdowns can result in high costs to fix the issue and shorten the life of the equipment.

One of the major challenges for any industry is worker shortage and skill gaps. AI-based systems can help bridge gaps by providing real-time maintenance guidance and automating complex diagnostics for better resource allocation and cost-effectiveness.

Operational Inefficiencies: Unplanned downtime results in inaccurate resource allocation resulting in low production and resource wastage.

For instance, the automotive industry can optimize operational efficiency ensuring their high-speed assembly lines are uninterrupted, capitalizing real-time monitoring with AI-based models.

Reputation Damage: Missed deadlines and inconsistent product quality can result in reputation damage to the manufacturers.

For example, food processing units can leverage AI-empowered predictive maintenance to detect anomalies in temperature-controlled environments to avoid spoilage.

These consequences indicate the need for proactive solutions such as AI-enabled manufacturing systems to shift manufacturers from reactive to predictive and preventive approaches.

How AI Optimizes Predictive Maintenance For Manufacturing?

AI-Powered Predictive Maintenance

AI plays a significant role in predictive maintenance facilitating enhanced data processing and decision-making. AI can process large data and complex sets gathered from multiple sources like sensors, machines, and historical logs quickly and accurately. In predictive maintenance, AI algorithms analyze complex data sets to provide more nuanced insights into equipment health.

Machine learning models help manufacturers stay ahead of maintenance issues and plan their production lines accordingly. With AI-powered predictive maintenance, companies can refine their forecasts as machine learning models constantly adapt, improving their predictions over time leveraging dynamic feedback loop and continuous learning. This allows maintenance teams to act proactively, reducing the risk of breakdowns and false alarms.

AI facilitates rapid communication by swiftly relaying information to the maintenance team and supervisors whenever intervention is required. It helps prompt immediate action and allows machines to operate with minimal delay.

Real-Time Monitoring and Anomaly Detection

AI constantly monitors equipment conditions in real-time allowing manufacturers to make proactive decisions. Anomaly detection algorithms help identify deviations from the normal performance of machines pinpointing potential issues before escalation. Additionally, an integrated predictive maintenance solution helps manufacturers gain insight into when maintenance would be required by accurately estimating the remaining useful life (RUL) of equipment. For example, manufacturers can optimize cost-effectiveness by reducing energy waste with enhanced machine performance and lowering material waste through accurate defect detection and predictive quality controls.

AI systems when integrated with existing enterprise asset management and maintenance systems translate actionable insights into efficient maintenance workflows making predictive maintenance more effective and timely. AI doesn’t just help in identifying potential issues – it communicates them effectively by sending instant alerts to the maintenance teams facilitating prompt action.

Manufacturers can perform maintenance during planned downtime with minimal impact on overall operations leveraging predictive maintenance insights derived with AI capabilities. Manufacturers can predict when a critical component might fail within hours by analyzing production floor data with AI, triggering preemptive action.

Advanced Pattern Recognition

Machine learning-based AI algorithms overpowers all other pattern recognition methods. It can identify subtle correlations and anomalies in machine data enabling timely maintenance. AI algorithms can detect early signs of wear or failure with anomaly detection, that may go unnoticed by traditional analytics and humans alike.

Furthermore, manufacturers can allocate resources more efficiently and effectively with optimized maintenance schedules based on equipment health and performance trends analyzed by AI algorithms.

Leveraging a 360-degree Data View

Accessing scattered data from documents, manuals, blueprints, and sensors is crucial for efficient machine maintenance. AI-powered systems connect these diverse data sources into a unified knowledge hub, enabling workers to quickly find the information they need. Whether it’s details about a specific machine or its components, having real-time data at their fingertips enhances the effectiveness of maintenance teams. This connected approach allows workers to address issues promptly, reducing downtime and ensuring smooth operations.

For example, if an air pump requires a fix, AI can instantly provide details about its make, model, and repair instructions. Predictive maintenance powered by AI goes a step further, alerting teams to potential issues like temperature deviations and guiding them with actionable insights. By indexing company data and making it searchable, AI eliminates the need for workers to rely solely on memory, saving time and boosting productivity with instant, reliable knowledge.

AI-Driven Production Scheduling

AI enhances production by dynamically adjusting schedules based on real-time data. If a machine is predicted to fail, the system can reassign tasks to other machines, ensuring continuous operations. Advanced algorithms optimize production plans, minimizing disruptions caused by maintenance activities.

Continuous Improvement with AI

AI models that are not stagnant undergo regular updates and retraining using new data to have continuous improvement in accuracy and relevance. This adaptive learning process of AI models boosts the accuracy of the predictive maintenance systems making it more reliable. It enables manufacturers to have a proactive maintenance approach to improve productivity, reduce costs, increase operational efficiency, and extend the lifespan of assets.

Benefits of AI in Manufacturing

AI is transforming the manufacturing industry making it more efficient, autonomous, and data-driven, here are the key benefits:

Lower Operational Costs

AI can reduce manufacturing costs over time, even if initial investments are high. Predictive maintenance minimizes expenses from machine breakdowns and downtime. Technologies like IoT-connected devices, and machine learning allow businesses to test products digitally and create affordable prototypes before mass production, cutting costs linked to trial-and-error processes.

Extended Machine Lifespan

To monitor equipment health, AI-driven predictive maintenance uses data gathered from different sources. The stakeholders receive alerts from predictive maintenance about potential or overdue repairs. With this proactive businesses can identify and address problems before costly and heavy failures. To ensure smooth operations and extended machine life-span regular machine checks are conducted using the data.

Quality Control

Manufacturers can have better quality control using machine learning to detect defects and irregularities in their products. With early issue detection manufacturers can resolve the issues efficiently and timely.

Enhanced Safety

AI innovations also improve workplace safety. For instance, computer vision can monitor and detect potential safety dangers to prevent accidents.

Why AQe Digital? Your Preferred Partner For Reliable AI Services

At AQe Digital, we understand that no business operations, objectives, and challenges are alike. That’s why we create robust and tailored AI solutions specifically for your business needs.

Domain Expertise: With years of experience in AI-driven manufacturing solutions, we help manufacturers reduce downtime, improve OEE, and cut maintenance costs.

Tailored Solutions: We train AI algorithms specifically for your machines, operations, and failure patterns to have accurate downtime predictions and facilitate proactive maintenance.

Seamless Integration: Our team integrates smooth connectivity with ERP, MES, SCADA, PLCs, and IoT-enabled assets for real-time data processing, remote monitoring, and AI-led insights.

Ethical & Responsible AI Practices: For reliable, transparent, ethical AI adoption our team follows stringent data security protocols, compliance (ISO, NIST, GDPR), and neutral AI decision-making.