For manufacturers and businesses alike, effective asset and equipment maintenance is essential to ensuring operational efficiency and extending the lifespan of critical machinery. The reason manufacturers emphasize maintenance capabilities is that they can significantly impact the productivity, operational efficiency, and resource utilization capacity of the manufacturing unit.

In the manufacturing facility’s operation budget, maintenance and repair costs are often one of the highest line items that affect the ROI and cost-effectiveness of the product. Most manufacturers operate with a dilemma about how often a machine should be taken down for service and how long they will have to hold production for unplanned breakdowns.

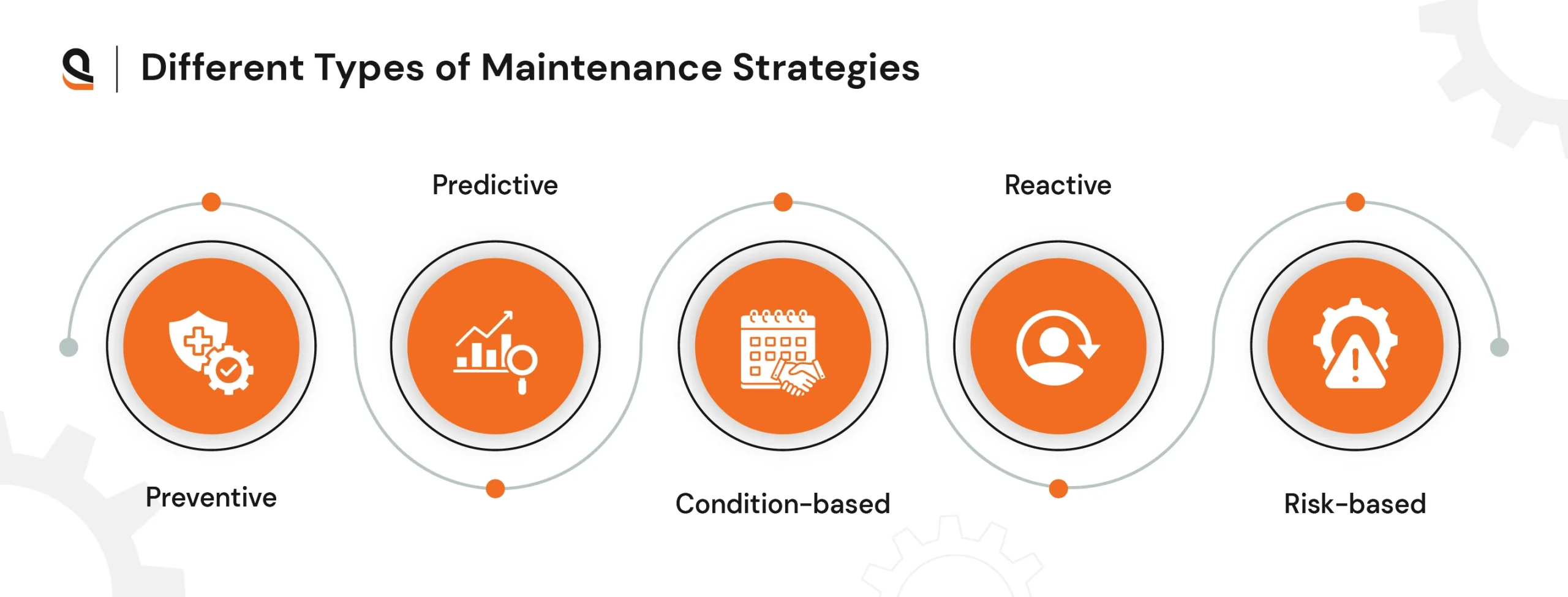

Maintenance strategies and approaches remain vital for manufacturers as machine downtime can reduce production capacity, increase expenses, and cause delays. Several maintenance strategies are followed by manufacturers to increase productivity and enhance operational efficiency. A predictive maintenance services provider helps you integrate AI into the manufacturing process, and the well-planned execution of maintenance strategies contributes to AI reducing downtime in manufacturing, helping manufacturers operate more efficiently.

In this blog, we are discussing preventive maintenance vs. predictive maintenance for manufacturers to enable organizations to have long-lasting productivity and streamline operational efficiency with better resource utilization.

What Is Reactive Maintenance?

When restoration or repair of the equipment is performed once the machine has already broken down, it is reactive maintenance. In simple words, manufacturers following this strategy allow their machines to stop and halt the production line at a time. Companies prefer maximizing asset output over equipment lifespan and other parameters by using machines to their limits, ignoring health and efficiency, and resorting to reactive maintenance. However, this strategy is effective until equipment fails, halting production.

Additionally, it can also lead machines to have harmful band-aid fixes, as each time the machine goes down, the technician only focuses on solving the issue rather than finding the root cause of the issue. Having such band-aid lauded machines leads to recurring asset problems, wasted budget, wasted resources, and it can even result in permanent system failure.

Businesses using Reactive Maintenance may suffer from reduced asset lifespan due to repeated emergency fixes and inefficient use of resources

What Is Predictive Maintenance?

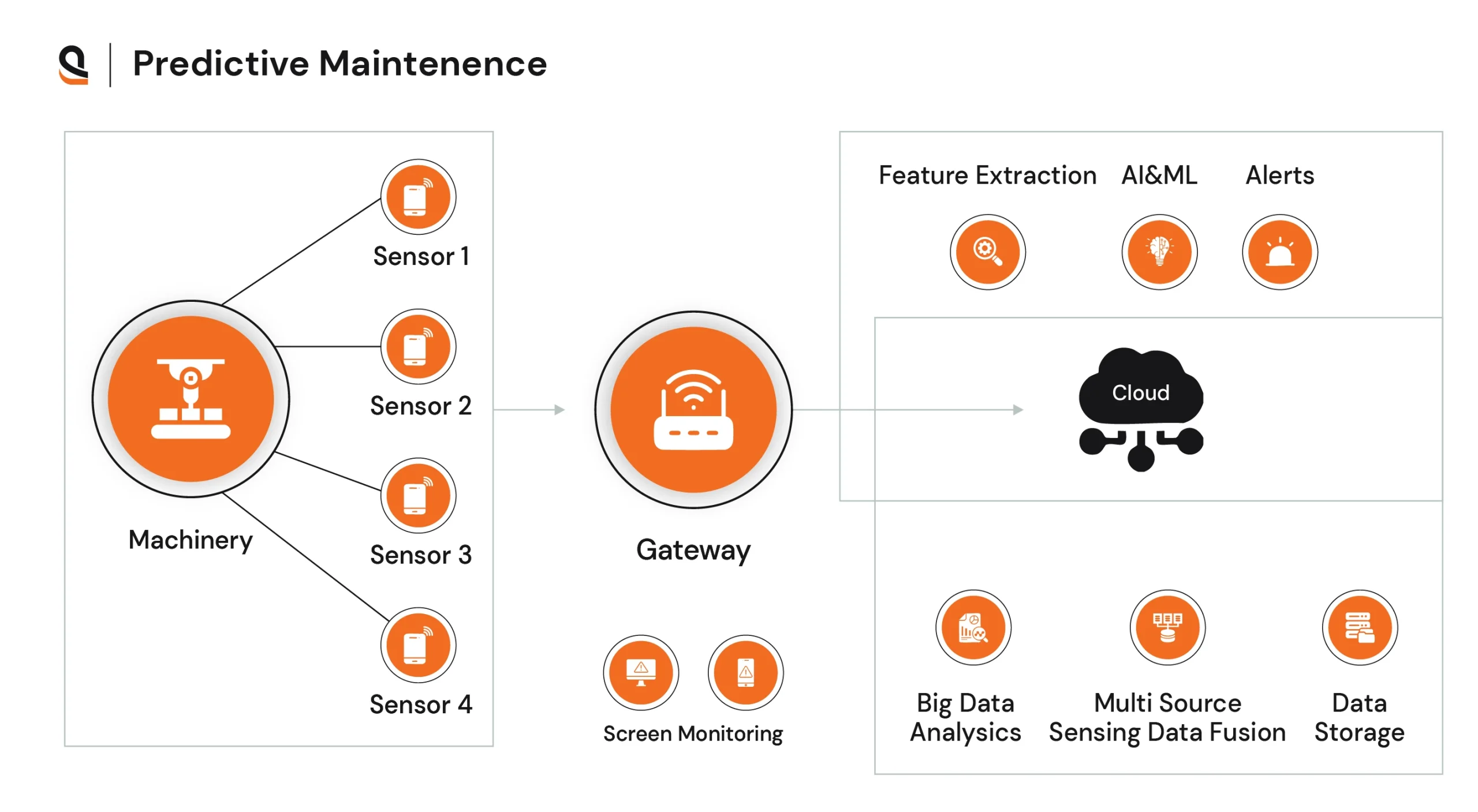

The predictive maintenance approach comprises advanced condition-monitoring tools and techniques such as Artificial Intelligence (AI), machine learning, and IoT-enabled sensors. It gets integrated with the manufacturing equipment, creating a network. These connected devices and equipment collect performance data and analyze it to predict equipment failure proactively. Predictive maintenance is not just a trend—it’s a proactive maintenance strategy that leverages real-time data and predictive analytics to detect equipment issues before they escalate.

With real-time data and continuous monitoring, it allow stakeholders to schedule production, maintenance, and resources for better productivity and efficiency. AI in manufacturing enables predictive maintenance that provides real-time and instant insights into the health status of equipment and entire manufacturing operations.

Apart from having better productivity, streamlined operations, and cost-effectiveness, predictive maintenance increases the equipment lifespan and saves expenses by avoiding major equipment failure, eliminating the need to purchase new machines. Predictive Maintenance, supported by AI, eliminates the guesswork involved in traditional maintenance approaches.

Which Maintenance Strategy Is Best For Manufacturers?

Having a strategy that predicts failure, extends machine lifespan, streamlines resource utilization, and offers several other benefits is undoubtedly the best maintenance strategy for manufacturers. AI in manufacturing enables predictive maintenance to drive innovation, productivity, compliance, security, and consistency for manufacturers, making it the most preferred approach for maintenance.

Maintenance strategies have evolved from time-based models to AI-enabled predictive models that are more efficient and cost-effective. A modern maintenance strategy focuses on preventing failure, not just responding to it, and this is where predictive maintenance plays a crucial role. AI in Manufacturing has transformed maintenance strategies from reactive guesswork to actionable intelligence. AI-driven maintenance strategies enable continuous improvement by using data to refine maintenance schedules and machine performance.

As per the study by the Boston Consulting Group (BCG), nearly 90% of manufacturing sector giants plan to integrate AI into their manufacturing processes. With AI in manufacturing, companies can collect sensor data, interpret patterns, and anticipate faults, making predictive maintenance more accessible than ever. Manufacturers should regularly evaluate their maintenance strategies to ensure alignment with production goals and asset health.

However, the ideal approach depends on a manufacturer’s specific needs, resources, and technological readiness. Integrating AI-driven predictive maintenance can be a game-changer and a digital transformation for manufacturers to boost innovation and efficiency, staying competitive in the market. The integration of AI in manufacturing empowers businesses to switch from outdated maintenance strategies to smarter, data-driven systems.

Maintenance is key to managing and optimizing manufacturing equipment and industrial assets, but implementing the right maintenance strategy with a reliable and experienced digital partner is even more important. Choosing the right maintenance strategy is essential for achieving long-term equipment reliability and plant efficiency.

Switch To Predictive Maintenance From Reactive Maintenance

With the speed at which manufacturers are innovating and market trends as well as demands evolving, one must adopt a system that is more focused on prevention and less on reaction. Unlike reactive maintenance, which waits for failures to happen, predictive maintenance solutions ensure minimal disruption and better cost management across production lines. Manufacturers who still rely heavily on reactive maintenance are at a higher risk of unexpected downtimes and higher repair costs.

Manufacturers need to show a readiness to embrace new technologies, workflows, and revamp manufacturing processes for better productivity and financial growth. AI integration into the existing manufacturing ecosystem demands nothing but patience and firm determination from manufacturers. The shift from reactive maintenance to predictive maintenance represents a significant milestone in the digital transformation journey of manufacturers.

AQe Digital and its experienced team seamlessly integrate AI tools and technologies into your manufacturing process and units without interrupting your ongoing processes, workflows, and operations.

How AQe Digital Helps Manufacturers Have Financial Benefits With AI Integration?

As a predictive maintenance solution provider, our AI experts strategically integrated AI technologies and tools into various aspects of the manufacturing process. Leveraging predictive analytics in manufacturing, we enable data-driven insights that support everything from automation to enhanced product quality. We empower manufacturers to streamline operations and take their manufacturing process to the next level.

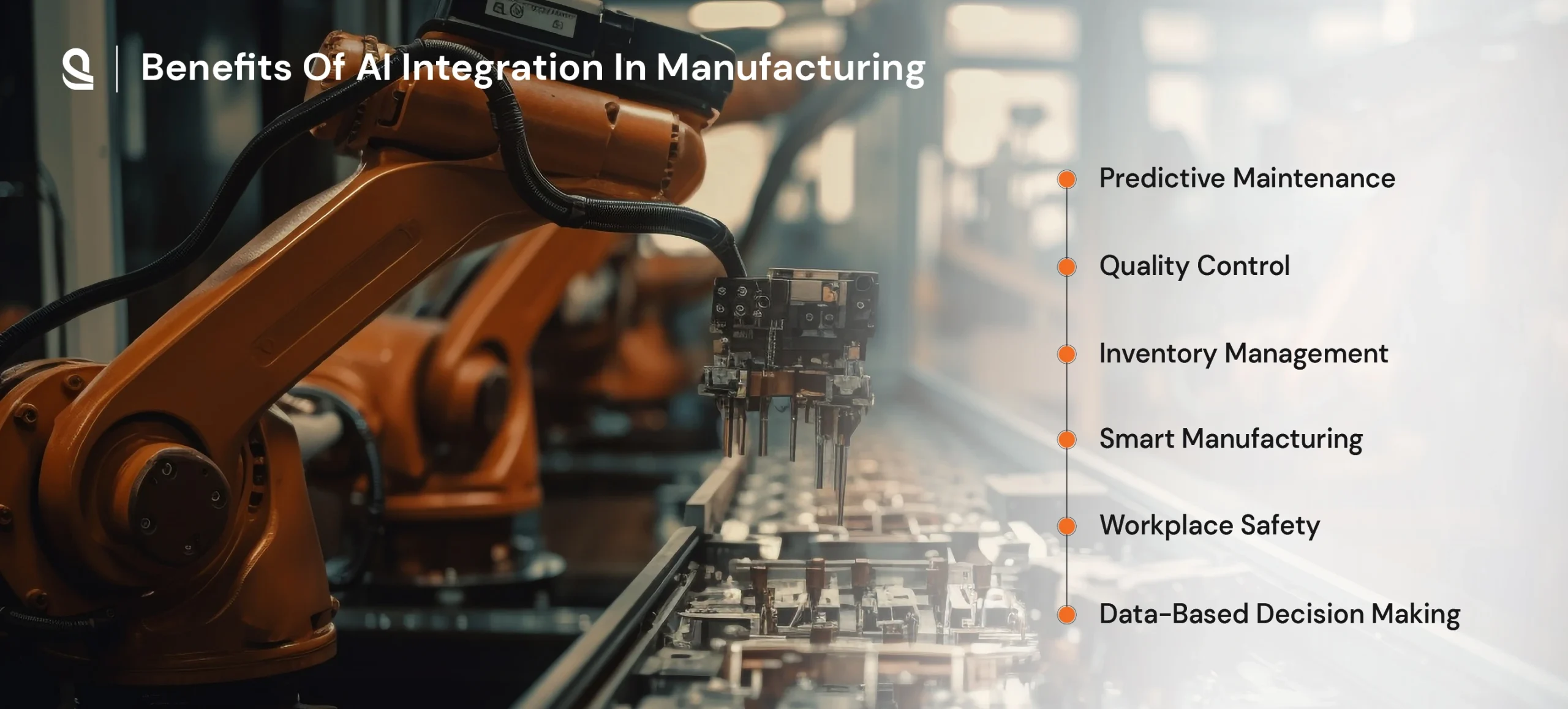

Benefits of AI In The Manufacturing Process:

Predictive Maintenance:

Our team enables manufacturers to analyze large amounts of data gathered from machine sensors and other devices to predict potential equipment failures. It helps with scheduling and planning costly downtimes and extending the equipment’s lifespan.

Financial Impact: Cost savings with better resource utilization, production scheduling, downtime scheduling, and timely repairs to avoid major equipment failures and costly repairs.

Quality Control:

AI-driven quality control is redefining standards in modern manufacturing. With the integration of AI-empowered visual inspection, we help manufacturers identify defects and inconsistencies in their products faster and more accurately. This helps ensure the production of high-quality products and reduces potential costs associated with returns and repairs.

Financial Impact: Enables cost-effectiveness by reducing defects by 20%-30%, minimizing waste, warranty claims, and recalls, and saving expenditure in rework costs.

Inventory Management:

With the integration of AI into supply chain management, our team helps manufacturers predict demand trends, optimize stock levels, and streamline logistics. AI-driven inventory management reduces storage and transportation costs and ensures a seamless flow of goods from the manufacturing chain to the market.

Financial Impact: Significantly cuts holding costs by 10-15%, preventing stockouts, and optimizing procurement. It helps free up working capital and reduces waste from overproduction.

Smart Manufacturing:

Our team integrates AI into the manufacturing process to enable machines to communicate seamlessly and make data-driven decisions. Our solution helps make the production process more efficient by decreasing the time needed to react to changes in the manufacturing chain, such as an increase in product demand or a supply shortage due to external factors.

Financial Impact: Boosts production efficiency, reduces energy consumption by 10%-20%, and lowers defect rates, improving profitability and sustainability. AI in Manufacturing not only supports predictive maintenance but also fosters smarter decision-making at every level of operations.

Workplace Safety:

With an AI-integrated manufacturing ecosystem, manufacturers can monitor working conditions, equipment health, temperature, and predict defect issues and alert stakeholders or workers to potentially hazardous situations.

Financial Impact: Reduces accidents, cutting legal, insurance, and compensation costs while preventing lost workdays and maintaining workforce productivity.

Data-based Decision Making:

Our team helps manufacturers have real-time and accurate data with AI integration. With real-time analyses, actionable insights, and accurate forecasts based on available data, AI can help businesses find new opportunities, develop data-driven business strategies, and optimize performance by identifying areas of improvement.

Financial Impact: Enhances manufacturing efficiency by 10-15%, enables faster market responses, optimizes production, and aligns supply chain strategies to maximize profitability.

Why is AQe Digital The Preferred Partner For AI Services?

At AQe Digital, we deliver comprehensive manufacturing IT solutions focusing on business growth, scalability, and operational efficiencies. Our global clients prefer our digital transformation services because:

- Tailored AI Solution: Our team delivers tailored solutions to address specific needs to optimize overall manufacturing processes.

- Seamless AI Integration: At AQe Digital, our team ensures easy integration with existing manufacturing systems without disrupting the ongoing operations and workflows.

- End-to-End Services: We ensure smooth AI adoptions for manufacturers with our comprehensive AI-related services that range from consultation to deployment and ongoing support.

- Customized AI Models: We deliver AI-driven solutions enabling high accuracy and efficiency for manufacturers by designing them, focusing on their unique challenges and requirements.

- Scalable Solutions: At AQe Digital, we deliver scalable AI solutions that ensure flexibility and adaptability to evolving business needs and trends.

Conclusion

Having the right maintenance strategy is essential for manufacturers of any size to have operations at any location around the globe. Being reactive to machine failures or downtime costs huge financial losses to businesses. Integrating AI into the manufacturing process can be a game-changer to drive innovation, automation, efficiency, and productivity with better ROI and financial growth. Combining multiple maintenance strategies with AI capabilities offers a hybrid approach that balances cost, efficiency, and risk management.

As your go-to digital transformation partner, we provide comprehensive manufacturing predictive maintenance services that range from consultation to implementation. Contact us to get connected with our AI experts to address your business goals, objectives, and challenges, leveraging AI capabilities and our 27+ years of experience.