Intelligent Automation for Production Planning & Scheduling

Turn data into actionable insights and automate your production planning with confidence—so you can focus on what matters most: delivering quality products on schedule.

Turn data into actionable insights and automate your production planning with confidence—so you can focus on what matters most: delivering quality products on schedule.

Our platform leverages advanced analytics and AI-driven forecasting to provide clear visibility into future demand trends.

This empowers your team to plan inventory more accurately, reducing the risk of both overstocking and shortages, and ensuring you consistently meet customer expectations.

We optimize the allocation of your workforce, equipment, and materials by analyzing real-time data and operational priorities.

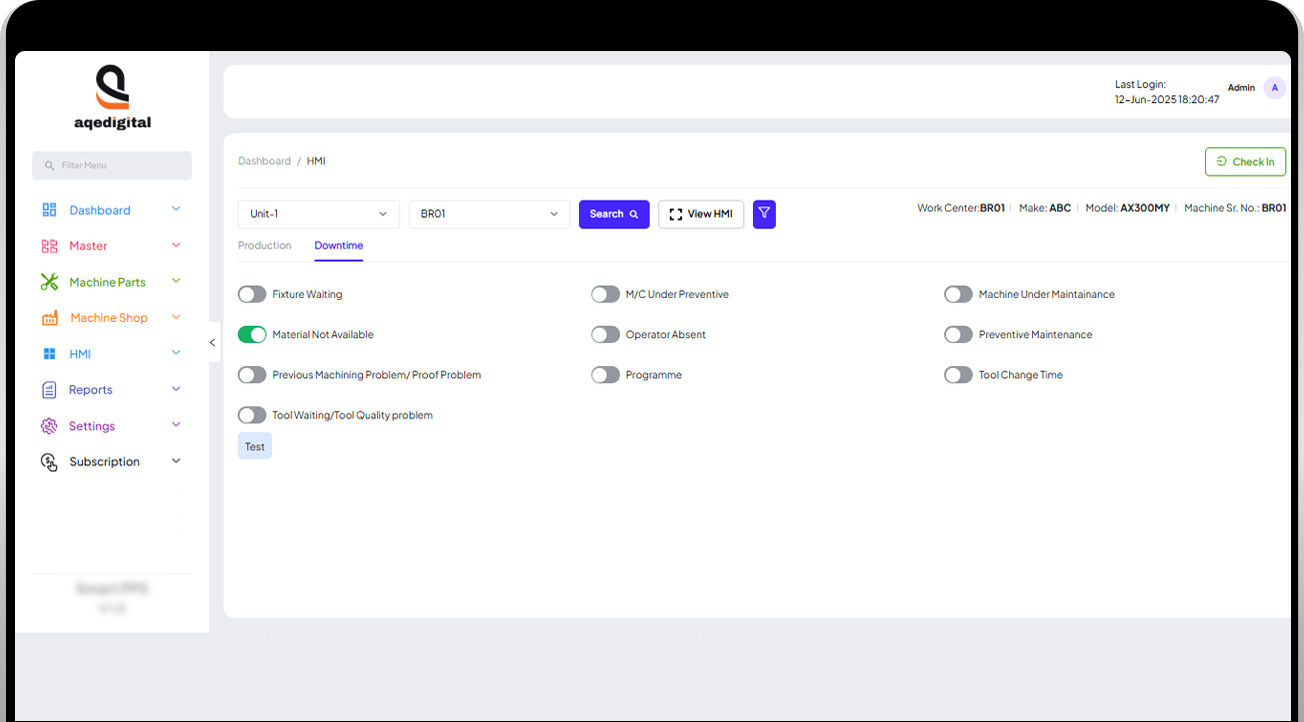

This ensures that resources are deployed where they’re needed most, helping you minimize bottlenecks, avoid unnecessary downtime, and keep production running smoothly.

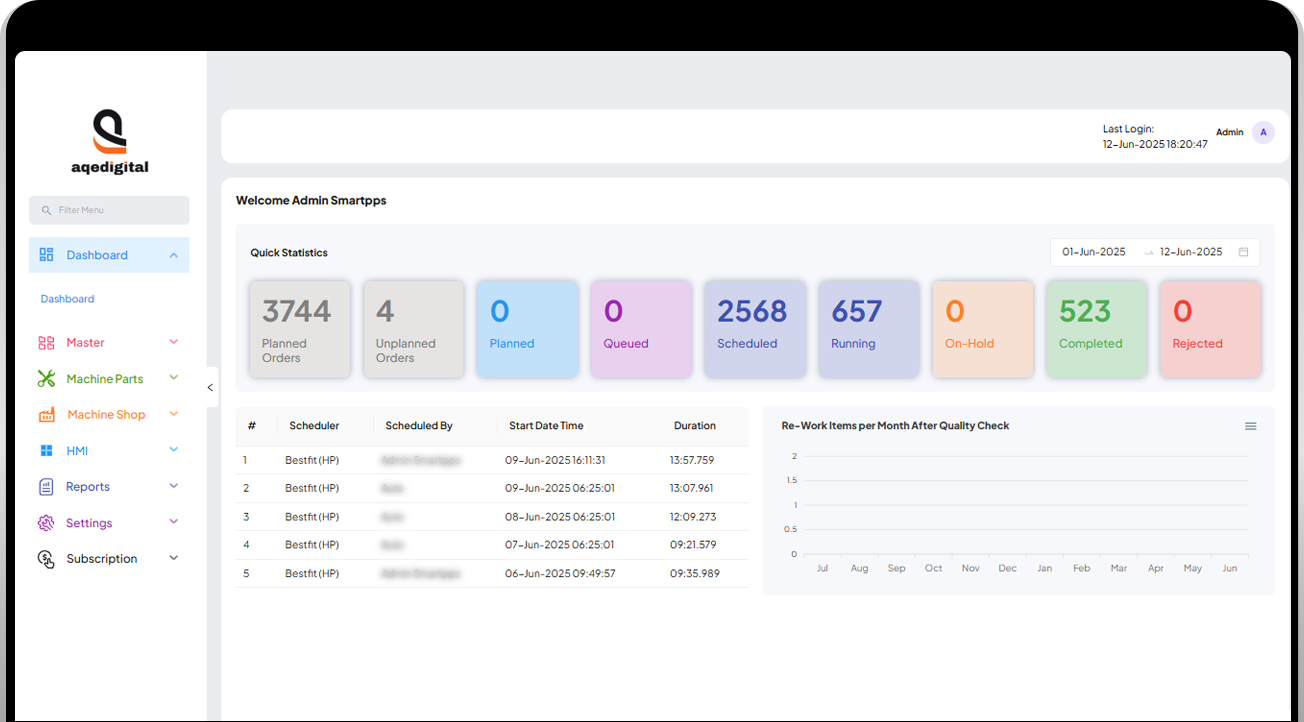

Our smart scheduling engine automatically updates your production plan in response to new orders, equipment issues, or last-minute changes.

This dynamic approach eliminates manual errors, streamlines coordination, and enables your team to adapt quickly without losing productivity.

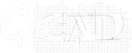

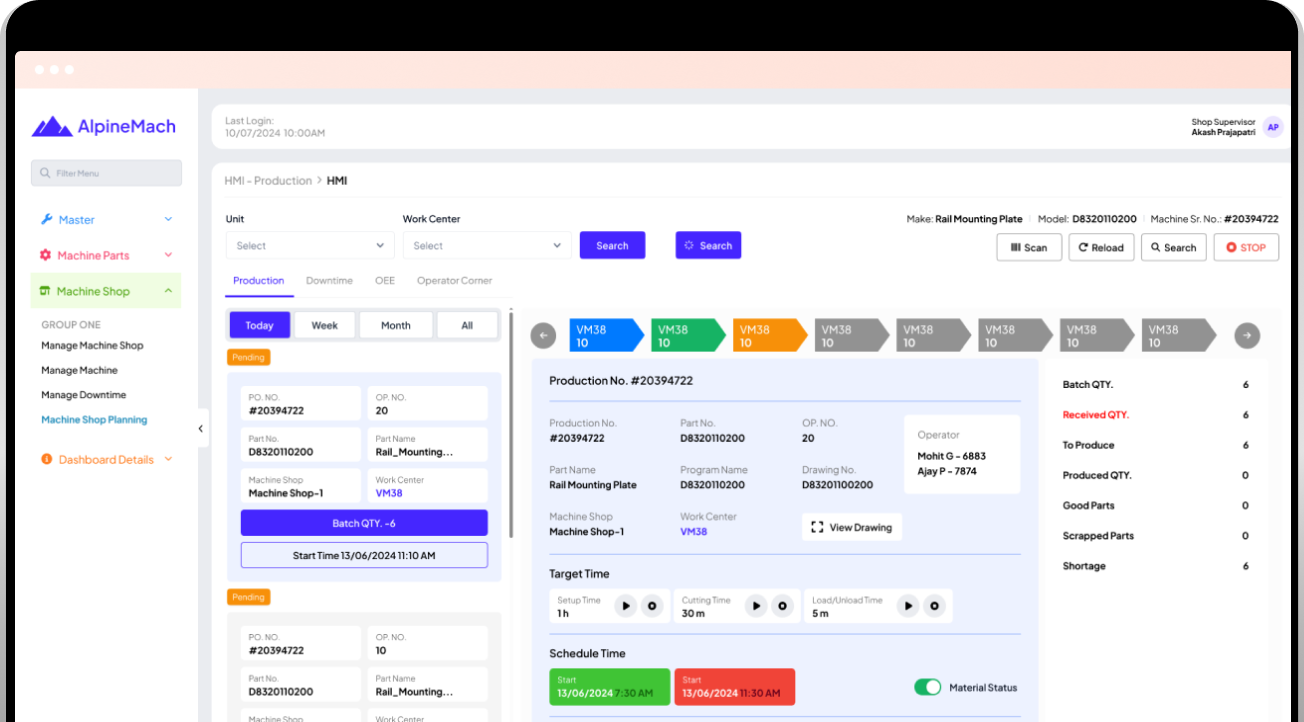

With our solution, you gain a live, centralized view of your entire operation. Real-time monitoring and actionable dashboards allow you to identify potential problems early, make informed decisions, and keep every stakeholder aligned—reducing the impact of disruptions.

Our system is built for agility, continuously adapting to changing shop floor conditions.

Whether it’s sudden order shifts or unexpected equipment downtime, our platform ensures your production plans remain accurate and executable, supporting uninterrupted operations.

Adaptive Scheduling Intelligence

Reduction in Maintenance Costs

Increase in Production Yield

ROI Within the First Year