Data analytics have positively impacted and transformed many industries, and manufacturing is not an exception. With the implementation and capitalization of data analytics, manufacturers have a lucrative opportunity to turn their data gathered from the procurement, production, and distribution processes into a valuable asset.

Though the nature of data and its volume have been a prevailing challenge, the manufacturer’s bigger challenge is leveraging the available data. Undoubtedly, data can boost overall productivity, profitability, and efficiency if utilized strategically, specifically in manufacturing data analytics. A Deloitte study highlights that implementing predictive maintenance can lead to a 70% reduction in equipment failures and cut maintenance expenses by up to 25%. In the manufacturing sector, this approach is increasingly being powered by AI-driven predictive analytics.

Why Data Analytics For Manufacturing Industry Is The Need Of The Hour?

Manufacturing data analytics is no longer a luxury; it’s a necessity for manufacturers to have predictive analytics in manufacturing. The evolving digital landscape requires well-planned data analytics in manufacturing to remain competitive and stay ahead of the curve.

Businesses can optimize their manufacturing workflows, improve product quality, streamline operations, and make informed decisions to drive growth and enhance overall productivity, capitalizing on manufacturing data analytics. Additionally, with predictive analytics in manufacturing, they can forecast machine downtimes, equipment failures and schedule maintenance with proper planning.

Streamlined operations, optimized production, and cost-effectiveness are major aspects that manufacturers are always looking for with data analytics in manufacturing. With manufacturing data analytics, manufacturers can extract valuable insights from the data and identify areas for improvement to increase efficiency and profitability.

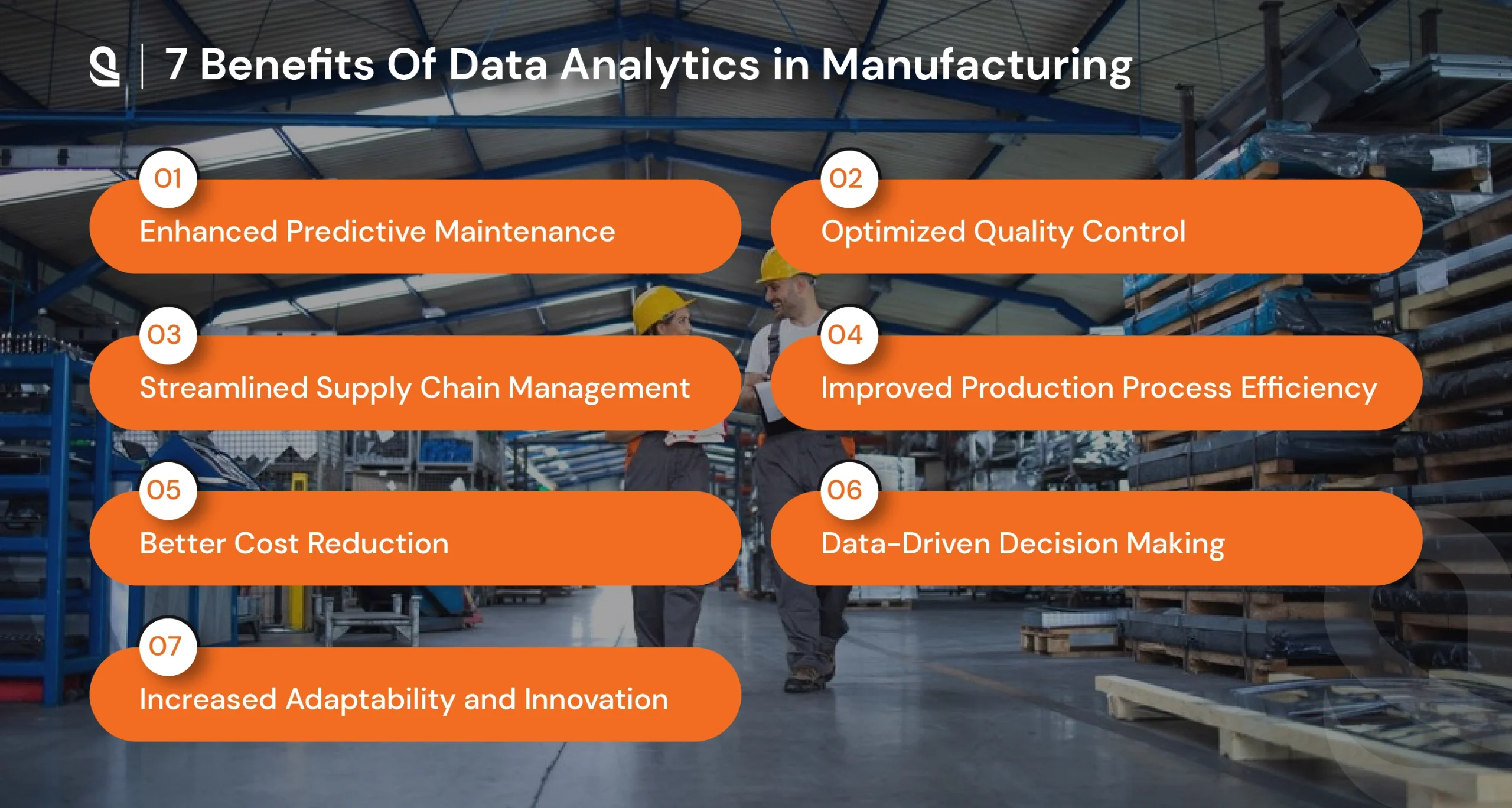

Top 7 Advantages Of Data Analytics in Manufacturing

1. Enhanced Predictive Maintenance with Manufacturing Data Analytics

Manufacturing data analytics-empowered predictive maintenance helps manufacturers accurately predict machine failures. The sensor data, machine learning algorithms, and predictive analytics in manufacturing help address maintenance needs in advance and minimize unscheduled downtime. Machine learning algorithms analyze patterns and detect anomalies signaling potential failures by leveraging the real-time insights gathered from sensor data integrated with IoT-enabled devices. Manufacturers can reduce unexpected disruptions by minimizing manufacturing downtime and enhancing productivity and resource allocation through predictive analytics in manufacturing. Manufacturing data analytics also enables timely interventions and proactive improvements in equipment reliability.

Benefits:

- Unexpected downtimes can be prevented with timely interventions through manufacturing data analytics. Predictive analytics in manufacturing helps minimize production disruptions and improve resource utilization.

- Save money with an extended machinery lifecycle by implementing data analytics in manufacturing. Predictive analytics in manufacturing helps curb emergency repair expenses or major equipment failures with proactive maintenance.

- Prevent excessive wear and tear on the machines by regularly monitoring and implementing timely interventions to extend their lifespan with predictive analytics in manufacturing.

2. Optimized Quality Control through Data Analytics for Manufacturing

Data analytics for manufacturing helps improve product quality by accurately reducing defects during production. Leveraging AI-powered vision systems, statistical process control, and real-time monitoring in the production cycle can help take product quality to the next level by using data analytics for manufacturing. Manufacturing data analytics helps maintain quality standards with minimal error, utilizing AI-powered vision systems that automatically detect defects through image recognition. Data analytics for manufacturing enables data-driven quality monitoring with statistical process control (SPC) to detect process variations and prevent potential defects in real-time. With uninterrupted monitoring, production anomalies can be identified instantly, which helps reduce waste, improve product consistency, and achieve cost savings through data analytics for manufacturing.

Benefits:

- Leverage manufacturing data analytics to reduce variation in product quality by standardizing production processes using data-driven insights.

- Data analytics for manufacturing helps control production costs by minimizing material wastage. It also helps decrease the need for reprocessing and detecting defects in the early stage of manufacturing.

- Data analytics services help have higher client retention rates by delivering flawless products, strengthening brand reputation, and meeting client expectations.

Download the Ultimate Guide to Solving Data Challenges in Manufacturing

Send download link to:

3. Streamlined Supply Chain Management in the Data Analytics Manufacturing Industry

Integration of data analytics in the manufacturing industry has revolutionized the importance and impact of data in supply chain management. From inventory optimization to demand forecasting, data analytics in the manufacturing industry helps ensure a resilient and agile supply chain. Manufacturing data analytics also helps manufacturers respond quickly to market demands and trends, leveraging real-time data visibility into inventory levels and logistics movement. Data analytics in the manufacturing industry enhanced demand forecasting accuracy, preventing stockouts and overstocking. Data analytics for manufacturing helps improve supply chain visibility by tracking materials and products throughout the supply chain, reducing inefficiencies and enhancing operational responsiveness.

Benefits:

- Manufacturers minimize unnecessary storage expenses by preventing overstocking and understocking, leveraging predictive analytics in manufacturing to optimize stock levels.

- From route optimization to risk management, data-driven insights help ensure a seamless flow of materials and products with manufacturing data analytics.

- Data analytics for manufacturing enables demand forecasting, and real-time analytics allow manufacturers to understand market demands and trends quickly.

4. Improved Production Process Efficiency with Data Analytics in Manufacturing

Process efficiency, streamlined workflows, and resource utilization are interconnected and represent the major concerns for any manufacturer. Data analytics in manufacturing helps identify inefficiencies, optimize workflows, and reduce waste, leading to improved process efficiency. Data analytics in manufacturing helps with continuous production process improvement by tracking key metrics, identifying areas requiring adjustments, and enabling real-time performance monitoring.

Benefits:

- Manufacturing data analytics provides better visibility into manufacturing processes, enabling optimized workflows and reduced cycle times, which in turn facilitate rapid production with improved quality.

- Data analytics services provide data-driven insights for better decision-making, enhancing overall efficiencies with reduced labor and resource wastage. It also enables better return on investment (ROI) and cost-effectiveness.

- Manufacturers can minimize waste through improved process control and optimizing resource utilization by leveraging data analytics in manufacturing.

5. Data Analytics and Manufacturing: Driving Cost Reduction

In the era of Industry 4.0, data analytics and manufacturing go hand-in-hand to drive cost-effectiveness. Manufacturing data analytics helps manufacturers drive cost efficiency by optimizing energy usage, reducing material waste, and lowering labor expenses. It is possible to identify probable savings across production processes by leveraging cost analysis. With predictive maintenance and demand forecasting, manufacturers can practice better resource utilization, planning, and scheduling of materials as well as labor.

Benefits:

- With advanced manufacturing data analytics, manufacturers can have smart energy-intensive processes to reduce overall power usage and costs.

- Eradicate excess consumption and unwanted scrap generation with enhanced material utilization and data-driven insights aligned with demand.

- With reduced unplanned downtime and automation, manufacturers can streamline labor-intensive tasks that help enhance productivity and operational efficiency.

6. Enabling Data-Driven Decision Making for Business Growth

Manufacturers can make data-driven decisions and find new opportunities by integrating data analytics in manufacturing. Accurate data analytics ensures long-term growth and competitiveness for manufacturers by providing actionable insights. Data visualization tools help simplify complex datasets and provide clear insights based on key business metrics. These insights help businesses identify areas for improvement, their strength, and hidden patterns to explore new opportunities and business strategies that drive growth.

Benefits:

- Contrary to traditional data management, advanced data analytics provide actionable insights and hidden data patterns that can help manufacturers make more informed decisions driven by data.

- Data analytics provides accurate demand forecasting that helps manufacturers plan and schedule production lines more efficiently to achieve better productivity and production processes.

- With data-backed decision-making and strategies, manufacturers can optimize resource allocation and utilization to reduce waste, leading to improved cost management and revenue generation.

7. Increased Adaptability and Innovation Through Manufacturing Data Analytics

Manufacturing data analytics enables organizations to stay competent, stay ahead of the curve, and innovate efficiently. Data analytics in manufacturing enables businesses to strategize and adjust production according to shifting consumer demands and market trends. With optimized design, testing, and production processes, manufacturers can accelerate product development. Additionally, manufacturers can use data-driven insights to implement new technologies such as AI, automation, and IoT, ensuring continued innovation and competitiveness.

Benefits:

- Real-time market analysis enables manufacturers to quickly adapt to shifting trends and consumer demands.

- Data-driven product development reduces time-to-market and enhances innovation efficiency.

- Integrating cutting-edge technologies ensures that manufacturers remain industry leaders and drive continuous improvement.

Why AQe Digital?

As a provider of data analytics solutions for manufacturing and your reliable go-to digital transformation partner, we focus on delivering the best services to manufacturers. What sets us apart from other data analytics solutions providers:

Domain-Specific Knowledge: With over 27 years of experience, our team possesses in-depth domain knowledge of the manufacturing sector, enabling us to deliver result-oriented manufacturing data analytics solutions that address industry-specific challenges.

End-to-End Solutions: At AQe Digital, we offer comprehensive data solutions to help manufacturers leverage their data to its full potential. From data collection to visualization to predictive modeling, we deliver comprehensive solutions.

Seamless Integration: Our team ensures your ongoing business operations stay uninterrupted, enabling smooth integration of data analytics solutions with existing IT infrastructure such as ERP, MES, IoT systems, software, and other devices.

Scalability & Flexibility: Whether for small manufacturers or large enterprises, our solutions scale effortlessly to meet evolving business needs, focusing on better ROI and operational efficiency.

Proven Track Record with Continuous Innovation: As a data analytics consulting services provider, AQe Digital has successfully transformed manufacturing operations for multiple clients. We stay ahead of industry trends, regularly updating our solutions to help manufacturers leverage the latest in data analytics technology.

Key Takeaways

- Data is a valuable asset that can help manufacturers transform their production process, optimize workflows, and standardize product quality.

- By predicting failures and leveraging data, manufacturers can enhance productivity and resource utilization while minimizing manufacturing downtime.

- AI-powered vision systems and real-time monitoring help improve product quality, reduce defects, and minimize material waste.

- Data analytics can help manufacturers have better production processes with deep visibility and continuous process monitoring.

- Actionable insights from advanced analytics improve production planning, business strategies, and resource allocation.