Quality control in manufacturing is a crucial factor in the success of any industrial operation. It ensures that every product meets quality standards, satisfies customers, complies with regulations, and upholds a positive brand reputation. However, traditional quality control (QC) methods often face challenges such as inconsistency, low throughput, and high operational costs.

This is where AI for quality control is transforming the industry. With advancements in AI image recognition and data analytics, manufacturers can now use automated quality inspections and enhance inspection quality. This leads into improving accuracy, reducing defect rates, and improving manufacturing efficiency.

As a trustworthy IT service provider in manufacturing, we deliver next-generation software solutions by leveraging AI image recognition and advanced data analytics to drive innovation in AI for quality control in manufacturing. Our technology empowers manufacturers to detect defects in real-time, generate predictive quality insights with automated quality inspection reporting, enabling faster, more consistent, and more reliable production cycles.

Challenges in Traditional Quality Control in Manufacturing

Quality control in manufacturing is of paramount importance in ensuring that their products conform to the highest standards. However, traditional QC practices tend to create bottlenecks in the very heart of manufacturers’ operations, be it in efficiency, cost, or product quality. Here follows a list of the challenges commonly encountered by manufacturers during QC implementation, and how AI image recognition and data analytics solutions provided by AQe Digital can bring them some resolutions:

- Human Error – Human inspections are liable to errors. Frustrations, inconsistencies, and subjective judgments could lead inspectors to miss defects.

- Slow Processing – Lengthy inspections become a bottleneck. This holds up the flow of production and ultimately hampers the throughput.

- Limited Scalability – Manual quality control in manufacturing can’t keep up with increased demand. Processes become ineffective and cannot meet high capacities.

- High Costs – Delayed defect detection bears a huge cost. Rework, recalls, and product failure will accumulate.

- Data Silos – Fragmentation of quality data is common. In the absence of a unified view, manufacturers cannot easily spot trends or identify the root causes.

5 Ways that Enhance Quality Control in Manufacturing through AI Image Recognition

Consistency in product quality is of great importance these days. However, a barrage of human errors, slow processing time, limited scalability, crippling costs, and many more challenge the field of traditional quality control in manufacturing.

At AQe Digital, we utilize advanced AI image recognition and data analytics to help solve these problems and make quality control in manufacturing much smarter, faster, and efficient. Let’s dive into the following great solutions that help resolve common QC challenges faced by manufacturers:

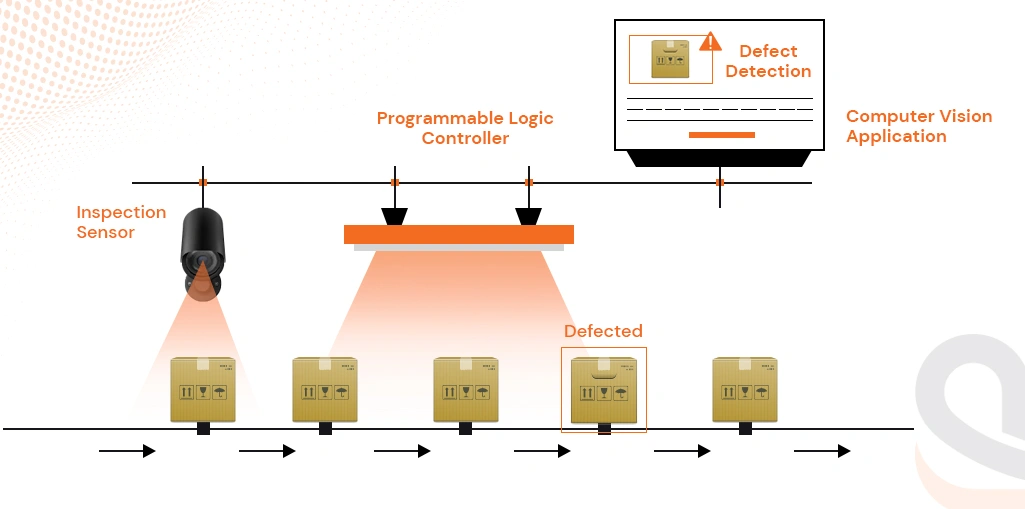

1. AI-Driven Defect Detection via Computer Vision

Addresses the Challenge: Human Error

With AI image recognition and computer vision, we automate defect detection, ensuring that every product is inspected with pinpoint accuracy. Using high-speed cameras integrated with IoT-enabled sensors, our custom services in AI in quality control for manufacturing models detect defects such as scratches, cracks, misalignments, and deformities in real time.

- Our customized services of AI for manufacturing quality control ensures complete reliability and independence from human errors. The AI does not tire or take subjective decisions; hence, every product must pass the same high standards.

2. Predictive Analytics for Quality Optimization

Address the Challenge: Slow Processing

Our predictive analytics platform utilizes AI for manufacturing quality control and machine learning algorithms to identify trends through analysis of production history and defect data. This is useful for a manufacturer in real-time so that they can reactively adjust their processes to minimize/or prevent defects. Additionally, AI image recognition is employed to visually inspect products, enhancing defect detection and improving overall quality control in the manufacturing process.

- By leveraging predictive analytics, we enable manufacturers to anticipate defects early and make timely process adjustments, reducing downtime and keeping production lines running efficiently. This proactive approach leads to quicker decisions, smoother workflows, and consistently higher output quality.

3. Automated Inspection & Classification

Address the Challenge: Limited Scalability

Our services in AI for quality control in manufacturing automatically carry out the classification of products against given quality standards. The AI in image recognition model moves rapidly to separate defective items for some rework or rejection, letting only the best of its kind products hit the market. With the integration of classifying systems based on AI in the robotic lines of production, we have made the entire QC process highly scalable.

- We leverage AI for manufacturing quality control automation for the process of classification so you can ramp your production without fear of sacrificing quality, so with your growing business, your QC system goes along.

4. Real-Time Quality Monitoring & Reporting Dashboards

Addressing the Challenge: High Costs

In our dashboards for real-time monitoring and reporting, interactive insights regarding the production process are available live. AI collects data from diverse QC checkpoints and aggregates it in a dashboard convenient for manufacturers to monitor and respond to real-time defects, compliance issues, and optimization requirements. Stopping the progress of defects allows timely intervention, which saves good resources from being directed into expensive fixes downstream in the production process.

- A dashboard minimizes any costs due to defects due to traceability; concerns can be addressed as soon as they develop. This way, we get improved quality assurance, with swift corrective actions mitigating recall and rework risks.

5. An AI-Integrated IoT Sensor for Precise Analysis

Addressing the Challenge: Data Silos

We bundled AI image recognition and IoT sensors together to collect real-time machine data, including temperature, pressure, and vibration, with precision analysis to detect early anomalies potential for defect developments before they become relativable. So basically, no critical information is overlooked, to give you a clear picture of your operations at all times.

- By bridging your data silos and facilitating a real-time, end-to-end view of production processes, our solution allows manufacturers to make truly data-based decisions and hence, lift product quality while reducing wastage.

Why AQe Digital: AI for Quality Control in Manufacturing

What we offer is not just a solution but a transforming, AI for quality control in manufacturing that is innovative in the way it transforms your manufacturing to a different scale. Being the leader in adopting the much-emphasized artificial intelligence, machine learning, and data analytics to enhance operational efficiency through a drastic drop in defects and maintain consistency in product quality, the industry leader dedicates efforts toward attaining the goal.

Investing in us does not only mean simply finding a quality control software ready for the future, but also one that outputs intelligent, rapid, and more precise results. Below are reasons as to why we are a trusted manufacturing IT solutions provider for our quality control in manufacturing uplift:

- Integration without effort such as plug-and-play compatibility –

AQe Digital, your digital transformation partner, ensures that not only does its AI for manufacturing quality control solution integrate seamlessly into your existing systems, but they have also ensured that they integrate into your ERP (Enterprise Resource Planning) systems, MES (Manufacturing Execution Systems), and IoT networks as well. - 99% accuracy in defect detection by AI for manufacturing quality control-

Design a system with data accuracy in manufacturing that never misses a detail, Whether it involves a tiny scratch, misalignment, or a crack, and provides the same consistent results across your entire production line. - A cloud-based dashboard capable of quality monitoring in real-time from anywhere and at any time –

As far as offering real-time quality tracking and reporting accessible at any moment, from anywhere, it’s AQe Digital’s cloud-oriented dashboards that take the prize. - Predictive insight into quality control for almost preventing defects before they occur –

We analyze historical data through real-time production trends to enable manufacturers to make adjustments to their systems early enough for operations to continue seamlessly without the costly impacts left from defects in the line.